Manufacture process for lithium ion battery negative pulp adopting lithium titanate material

A lithium-ion battery and manufacturing process technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle stability, potential safety hazards, and large volume changes, and achieve stable discharge voltage, high safety, and excellent cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

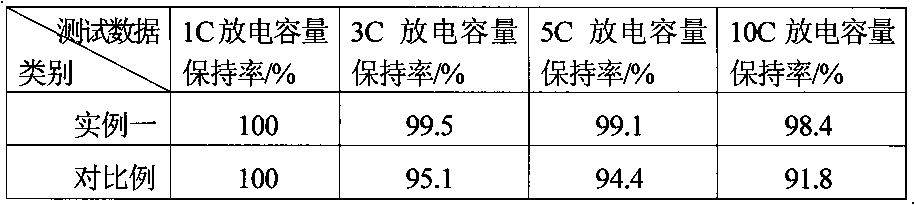

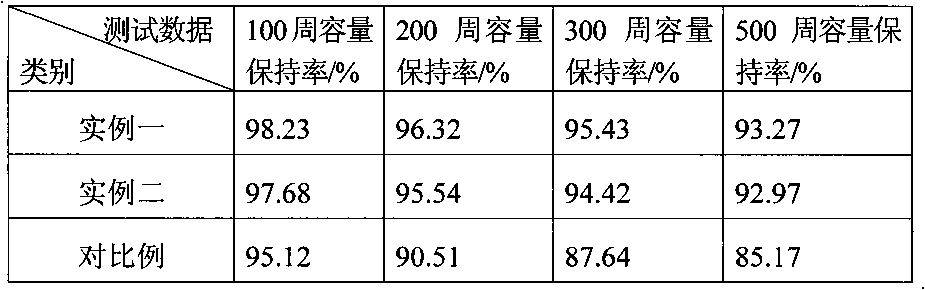

Embodiment 1

[0025] Making stacked lithium-ion power batteries

[0026] The production method of the negative electrode sheet:

[0027] Dissolve 8 grams of polyvinylidene fluoride in 80 grams of N-methylpyrrolidone, and use a defoaming mixer to carry out vacuum stirring (rotation 15Hz, revolution 25Hz) for 2.5h; then add 3 grams of carbon black SUPER-P, vacuum stirring (rotation 15Hz, revolution 30Hz) for 1.5h; finally add 100g lithium titanate powder and 30g N-methylpyrrolidone, stir in high-speed vacuum (35Hz rotation, 40Hz revolution) for 4h, and finally stir slowly (15Hz rotation, 25Hz revolution) for 1.5h , the negative electrode slurry was obtained after standing for 1 h in vacuum to remove air bubbles.

[0028] Coat the negative electrode slurry on both sides of a 15um thick aluminum foil, remove the solvent N-methylpyrrolidone at 120-130°C, control the thickness of the negative electrode sheet at 170±10um, and control the thickness of the negative electrode sheet after rolling At...

Embodiment 2

[0038] Winding lithium-ion power battery

[0039] The production method of the negative electrode sheet:

[0040] Dissolve 10 grams of polyvinylidene fluoride in 90 grams of N-methylpyrrolidone, stir in vacuum (rotation 15Hz, revolution 25Hz) for 3.5h; then add 4.5 grams of carbon black SUPER-P, and vacuum stir (rotation 15Hz, revolution 30Hz) 1.2h; finally add 30g of lithium titanate powder, stir in vacuum for 0.5h, then add 70g of lithium titanate powder and 30g of N-methylpyrrolidone as a solvent, stir in vacuum (rotation 35Hz, revolution 40Hz) for 5h, add titanic acid The process of lithium powder was stirred for a total of 5.5 hours. Finally, stir at a slow speed (rotation 15Hz, revolution 25Hz) for 1.2h, and leave to stand for 0.5h to remove air bubbles in a vacuum to make negative electrode slurry.

[0041]Coat the negative electrode slurry on both sides of a 15um thick aluminum foil, remove the solvent N-methylpyrrolidone at 120-130°C, control the thickness of the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com