Method for manufacturing organic thin film transistor realizing patterning and automatic-modification interface in one step

A patterned, organic semiconductor technology that can be used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve problems such as carrier traps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (3) Fabrication of organic thin film transistors

[0043] Drop film standing method:

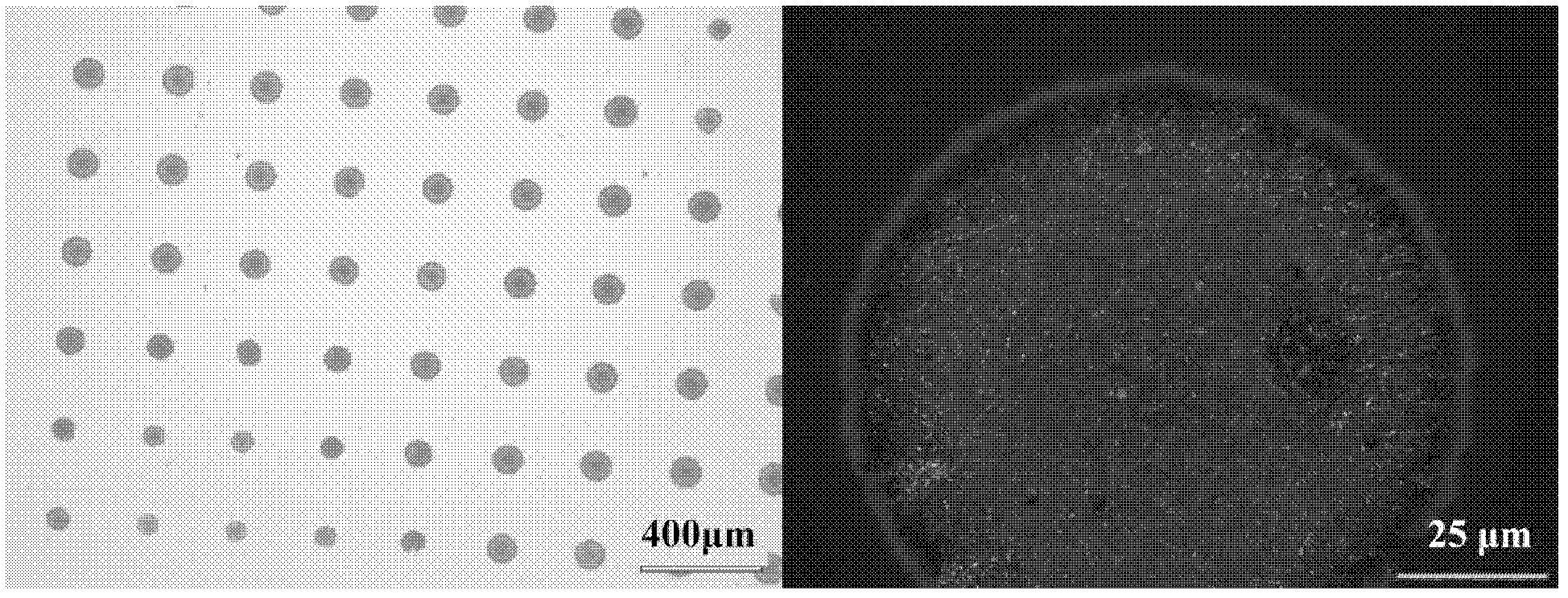

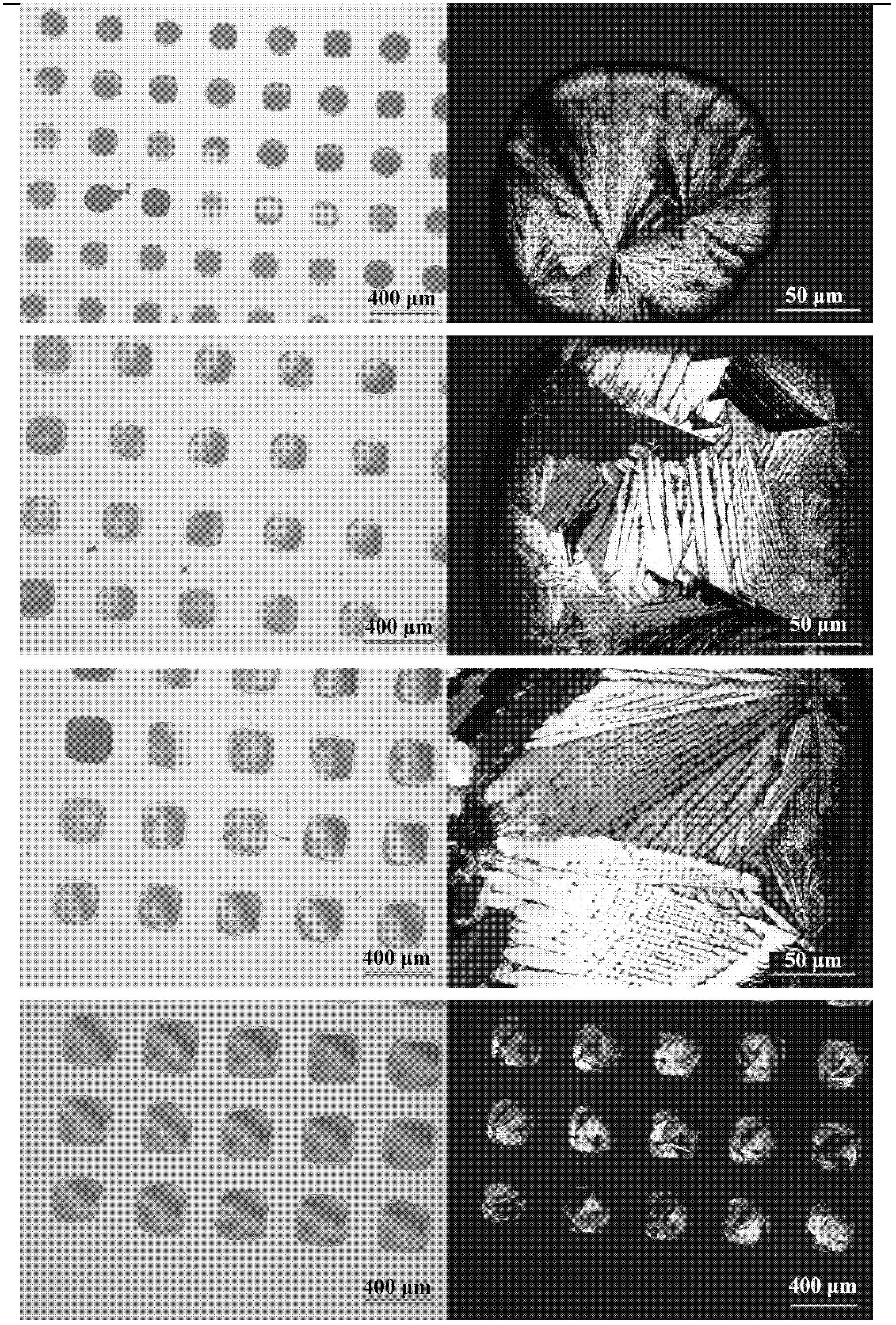

Embodiment 1

[0045] Dissolve Tips-pentacene and polystyrene (PS) at a ratio of 80% / 20% in chlorobenzene at 40°C, let it stand and filter to make a solution with a concentration of 3%, and then homogenize the solution Drop it onto the surface-selectively treated silicon wafer with gold electrodes at an inclination angle of 15°-30°, let it stand until the film is uniform, and post-bake it on a hot stage at 120°C for 30 minutes to prepare a film.

Embodiment 2

[0047] Dissolve Tips-pentacene and polystyrene (PS) at a ratio of 60% / 40% in chlorobenzene at 40°C, let it stand and filter to make a solution with a concentration of 3%, and then homogenize the solution Drop it onto the surface-selectively treated silicon wafer with gold electrodes at an inclination angle of 15°-30°, let it stand until the film is uniform, and post-bake it on a hot stage at 120°C for 30 minutes to prepare a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com