Automatic pressing and detecting machine for iron cores

A technology of automatic pressurization and detection machine, which is used in measuring devices, inductance/transformer/magnet manufacturing, instruments, etc., can solve the problems of high labor intensity of staff, non-standard inspection, slow pressing speed of hydraulic press, etc., to avoid Dangerous risk of human operation, simple and clear operation, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

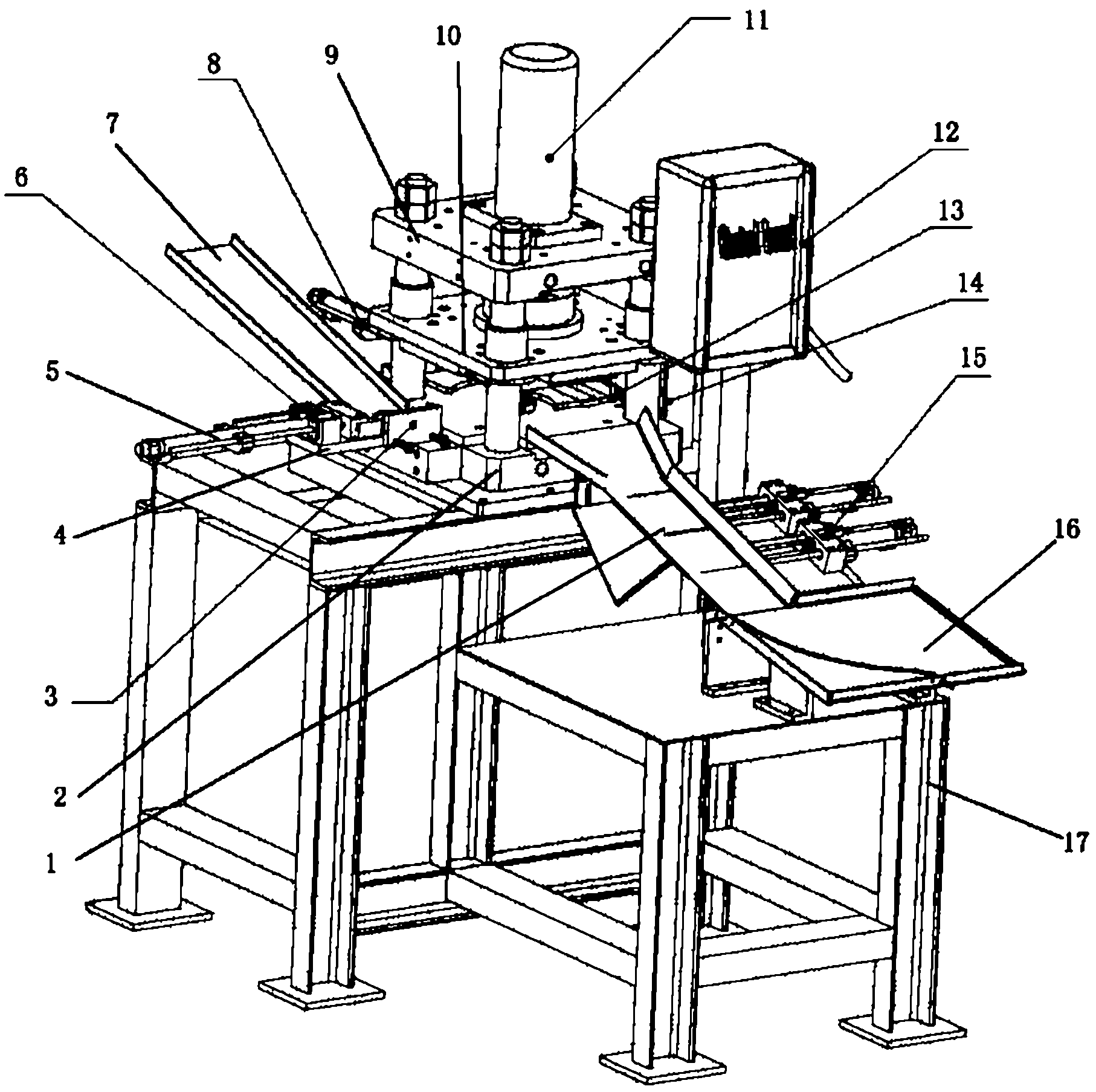

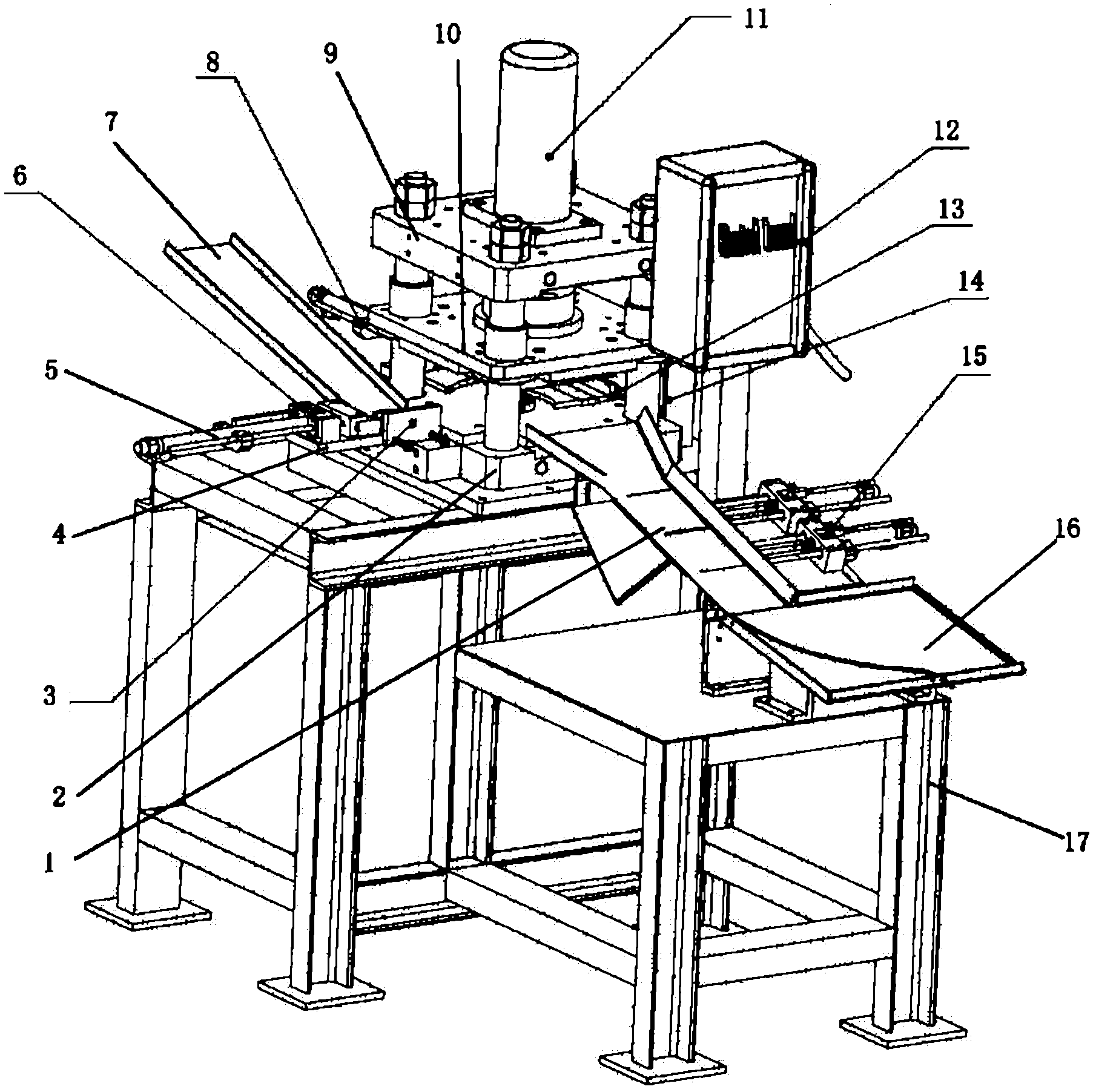

[0023] Such as figure 1 The shown iron core automatic pressurization detection machine includes a support 17 composed of a first support and a second support, and is characterized in that: the first support is provided with a press for pressing the iron core. The pressing device is also provided with a pushing mechanism 8 that pushes the pressed iron core out of the pressing device, and the left side of the pressing device is connected with a The feeding mechanism, the feeding plate 7 is connected on the described feeding mechanism, the front side of the described compacting device is connected with the material guide groove 1 connected with the charging pan 16, and the described compacting device is also provided with The grating detection device 14 for detecting the height of the pressed iron core also includes a control device for controlli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com