Graphene film sensitized D-shaped optical fiber surface plasmon resonance (SPR) sensor and preparation method thereof

A graphene film and sensor technology, applied in the fields of optical engineering, fiber optics, and materials engineering, can solve the problems of low detection sensitivity of SPR structure, easy oxidation of silver film, etc., and achieve good chemical stability, compact structure, and high sensitivity. The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

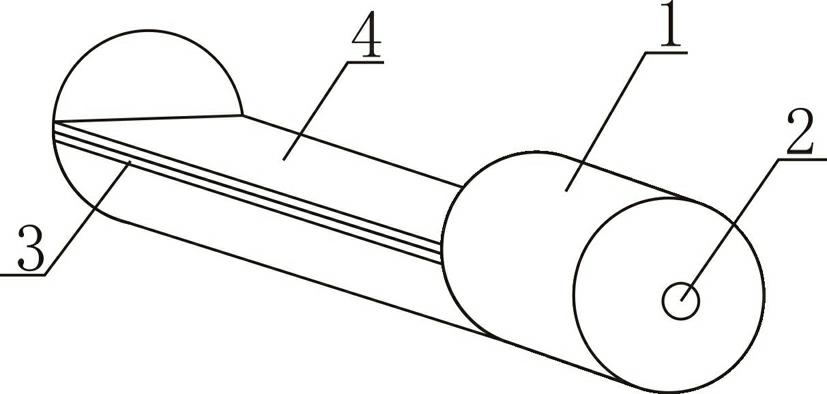

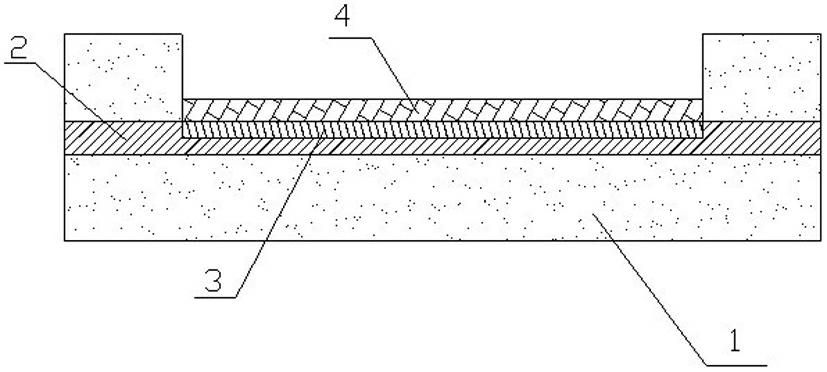

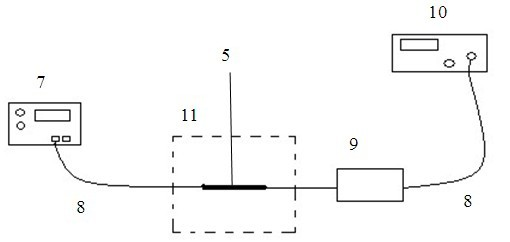

[0026] Such as figure 1 and figure 2 Shown, a kind of preparation method of the D-type optical fiber SPR sensor based on graphene film sensitization:

[0027] First prepare the D-type optical fiber: grind the middle section of the ordinary multimode optical fiber from the side, the grinding length is 1-3 cm, the depth of the D-shaped groove is equal to the radius length of the optical fiber, so that the bottom of the grinding groove is smooth and smooth, and the smoothness is maintained at 1A. Of course, it can also be prepared according to other existing methods.

[0028] Then a silver film layer is prepared on the polished surface of the D-type optical fiber; a metal silver film layer of about 50 nanometers is plated on the bottom of the D-type optical fiber groove by a chemical deposition reduction method.

[0029] Finally, on the surface of the metal silver film layer, a CVD method (chemical vapor deposition method) is used to grow a graphene film layer with a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com