Sensor fixing device for measuring unsteady force by utilizing shock waves to load and fix particle swarm

A technology of fixing particles and fixing devices, which is applied in measuring devices, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., can solve the problem of error rationality without effective experimental verification, and achieve the effect of facilitating experimental work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawings and examples.

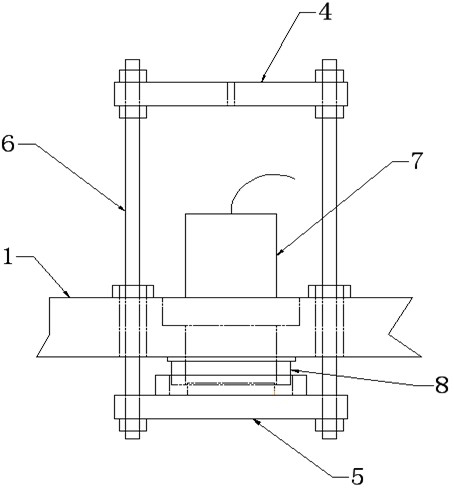

[0023] Such as figure 1 , figure 2 As shown, the present invention includes two parts: a base and a cage-shaped support, wherein the base includes: an upper cover plate 1 of the base, a base plate 2 and a lower cover plate 3 of the base, wherein the base plate 2 and the lower cover plate 3 of the base structured as Figure 5 , Figure 6 Shown; Cage-shaped bracket comprises: cage-shaped bracket top cover 4, cage-shaped bracket bottom cover 5, connecting rod 6 and sensor threaded connection ring 8 (its structure is as follows Figure 7 shown), wherein the connecting rod 6 is fully threaded; the two sides of the four base plates 2 are respectively provided with threaded holes, and the upper cover plate 1 of the base and the lower cover plate 3 of the base are also respectively provided with threaded holes. These three components are connected into a whole wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com