Axial-flow pump for particle image velocimetry and particle image velocimetry method

A particle image velocimetry and axial flow pump technology, which is applied to components of pumping devices for elastic fluids, axial flow pumps, pumps, etc., can solve the problems of increased processing costs, complex structures, and very different structural forms Long distance and other problems to achieve the effect of improving measurement accuracy and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

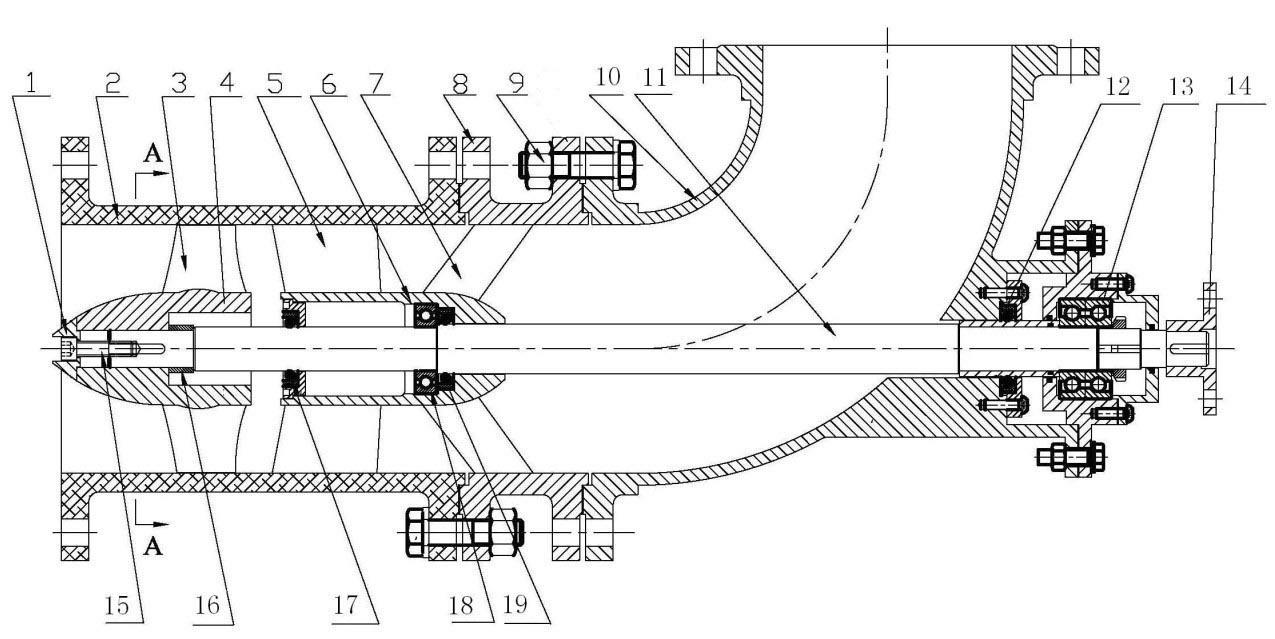

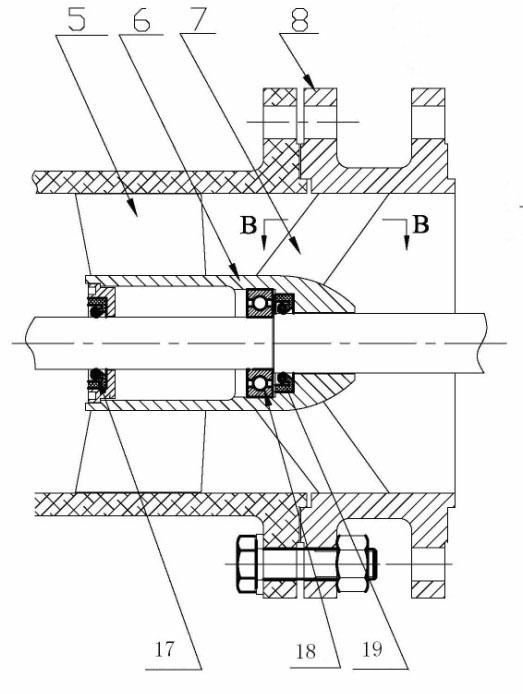

[0019] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] exist figure 1 and figure 2 Among them, the axial flow pump consists of water guide cone 1, impeller blade 3, impeller hub 4, guide vane blade 5, guide vane hub 6, transparent square plexiglass cylinder 2, streamlined rib 7, flange 8, bolt 9, pump Shaft 11, elbow section 10, deep groove ball bearing A13, deep groove ball bearing B18, screw 15, shaft sleeve 16, oil seal A12, oil seal B17, oil seal C19 and coupling 14 and other parts. The impeller blade 3 and the impeller hub 4 are welded and fixed to form an impeller, and the guide vane 5 and the guide vane hub 6 are welded and fixed to form a guide vane. Both the impeller and the guide vane are inside the transparent plexiglass tube; The radial gap between the edge and the transparent square plexiglass cylinder 2 is 0.5mm. When the impeller rotates with the pump shaft 11, the impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com