Anchored roadbed widening method

A subgrade and road technology, applied in roads, roads, buildings, etc., can solve the problems of complex construction steps and insignificant settlement effect, and achieve the effect of controlling uneven settlement, ensuring bearing capacity, and avoiding sliding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

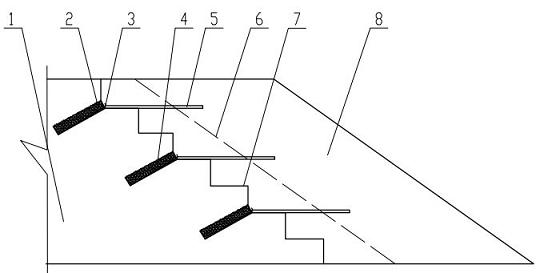

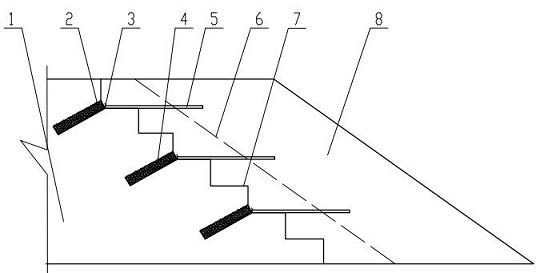

[0024] According to attached figure 1 It can be seen that the present invention specifically relates to a method for widening an anchored road subgrade, and the specific steps of the method are as follows:

[0025] 1. The slope of the old subgrade 6 is cut by 30-50cm, and the surface soil and humus are removed;

[0026] 2. Excavate steps 7 with a height of 60-100 cm and a width of 90-150 cm on the slope 6 of the old subgrade from the ground;

[0027] 3. Drill anchor holes 2 with a diameter of φ80-100mm at the intersection of the vertical surface and the horizontal surface of the excavated steps along the direction of 15-30 degrees to the horizontal surface. The depth of the anchor holes 2 is 3-5m, and the distance along the line is about 2m;

[0028] 4. Put a steel bar 4 with a diameter of 8-10mm in the anchor hole 2, the steel bar is exposed 5-10cm, and the end hook 3 is folded upward to form an angle of 90 degrees, and the exposed part of the steel bar 4 is treated with ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com