Rod material precision shear mould

A cutting die and precision technology, applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problems of many section defects, poor quality of blank section, and low precision of blank blanking, etc., to achieve The effect of improving section quality, reducing shear deformation, and improving blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

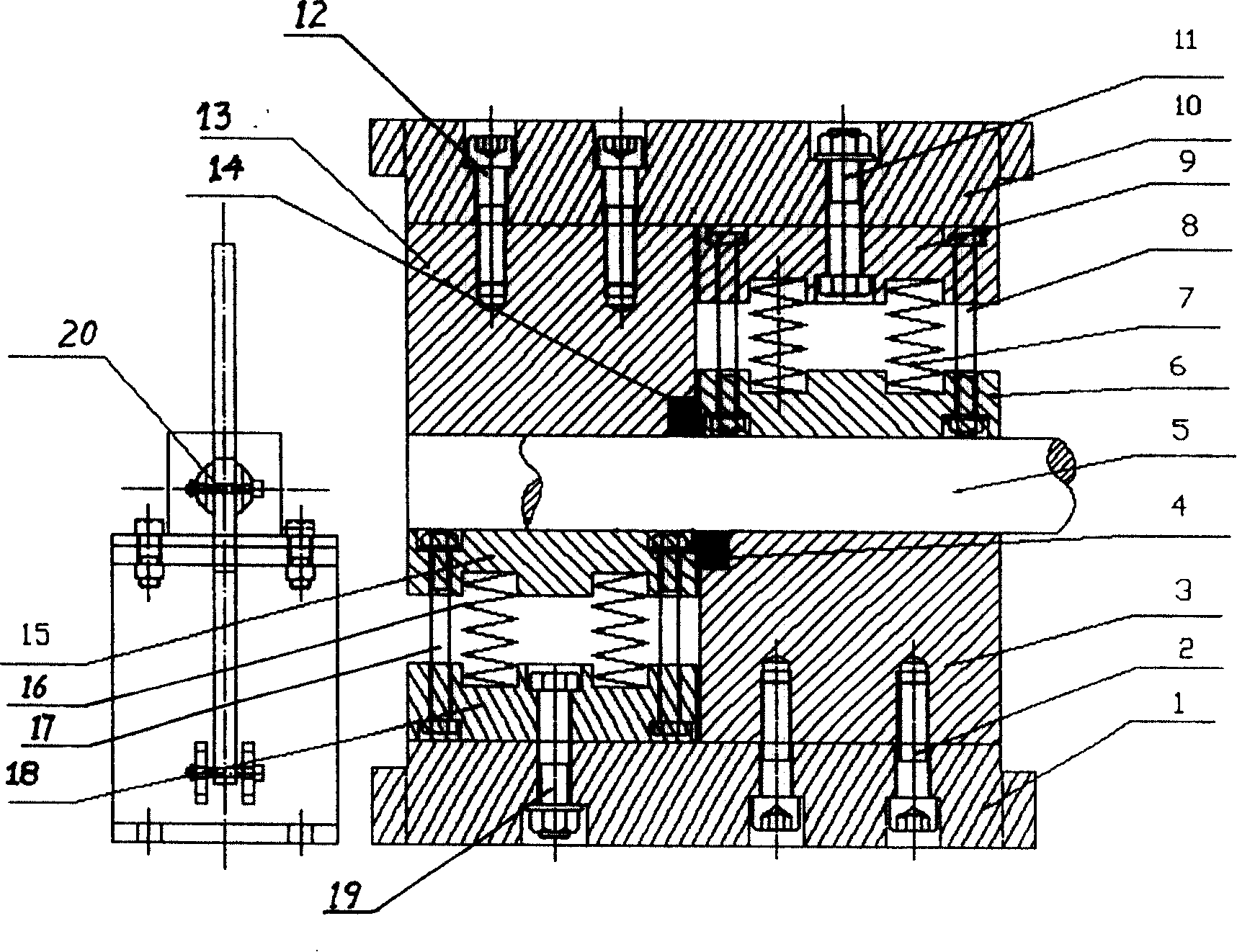

[0009] As shown in the accompanying drawings, the bar stock precision shearing die in this embodiment includes a lower template 1, a lower fixed knife rest 3 mounted on the right side of the lower template 1 through bolts 2, and a lower blade 4 arranged at a corner of the lower fixed knife rest 3 Upper formwork 10, be located at upper fixed knife rest 13 on the left side of upper formwork 10 by bolt 12, be located at the upper blade 14 of upper fixed knife rest 13 corners, wherein: it also comprises by upper clamping block 6, upper clamping The upper clamping device that spring 7, upper connecting bolt 8 and upper fixing block 9 constitute and the lower clamping device that is made of lower clamping block 15, lower clamping spring 16, lower connecting bolt 17 and lower fixing block 18; The clamping block 6 is connected with the upper fixing block 9 through the upper connecting bolt 8, the upper clamping spring 7 is arranged between the upper clamping block 6 and the upper fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com