Method for removing rolling oil from double surfaces of rolled copper foil

A technology of rolling copper foil and rolling oil, which is applied in the direction of metal rolling, metal rolling, and workpiece surface treatment equipment, etc., can solve the problems of easy oxidation of rolled copper foil, low efficiency, and slow line speed, etc., and improve labor efficiency. Productivity, enhancement of degreasing effect, and effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

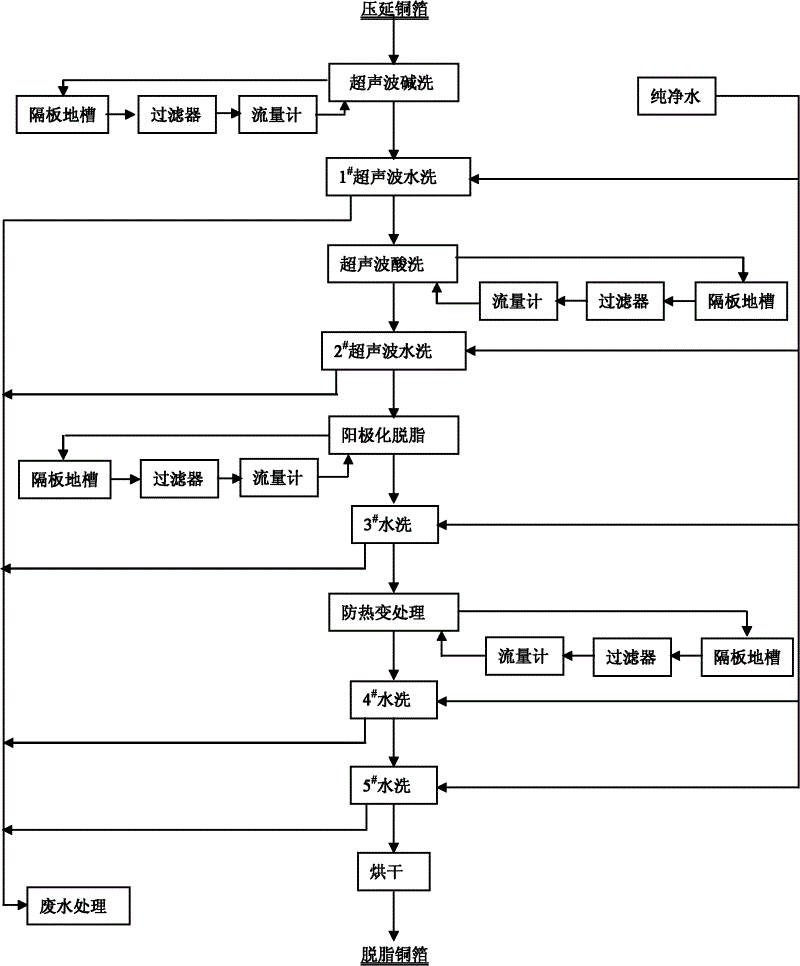

Image

Examples

Embodiment 1

[0047] (1) Ultrasonic alkaline degreasing; (≥22KHz)

[0048] Alkaline special degreasing agent: mixed lye with sodium hydroxide and sodium carbonate, and added OP emulsifier non-ionic surfactant. The solution ratio is: NaOH: 50g / l; Na 2 CO 3 : 20g / l; OP emulsifier: 2g / l.

[0049] Solution temperature: room temperature

[0050] Solution flow: 1 ~ 3M 3 / Hr

[0051] (2) 1# ultrasonic pure water washing; (≥22KHz)

[0052] Conductivity≤50μs / cm, water volume 1M 3 / Hr. Dip + spray form

[0053] (3) Ultrasonic acid degreasing; (ultrasonic frequency: ≥22KHz)

[0054] Sulfuric acid: 8% (weight percent concentration)

[0055] OP emulsifier (non-ionic surfactant): 2 g / l.

[0056] Flow: 1~3M 3 / Hr

[0057] Solution temperature: room temperature

[0058] Adopt separate circulation system, three-stage clapboard landing tank for oil filtration and heating filtration.

[0059] (4) 2# ultrasonic pure water washing (≥22KHz)

[0060] Conductivity≤50μs / cm, water volume 1M 3 / Hr. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com