Purification and recovery plant realized by means of directly calcining lime by aid of primary high-temperature flue gas of converter

A high-temperature flue gas, calcined lime technology, applied in furnaces, furnace components, manufacturing converters, etc., can solve the problems of environmental pollution, heat loss, high equipment operating costs, and achieve high safety, reduce operating steps, and reduce operating costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

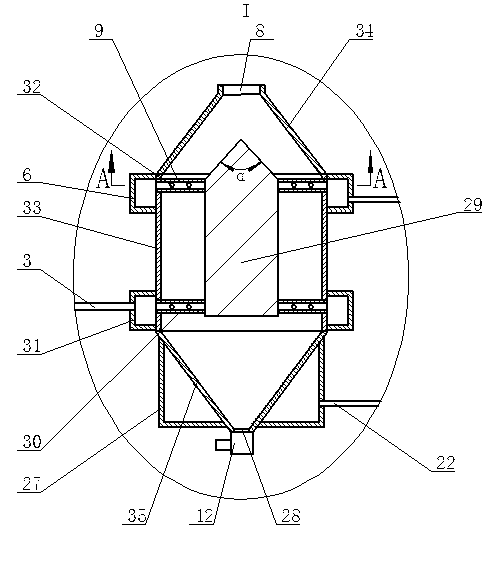

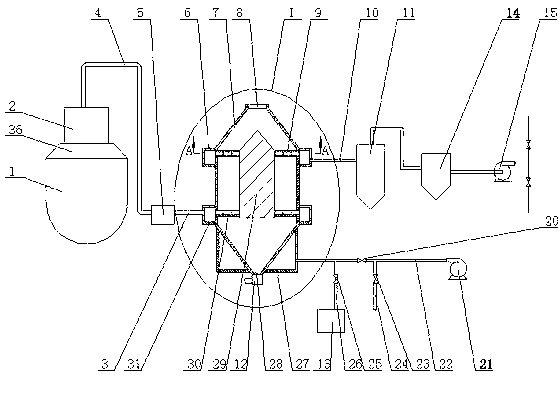

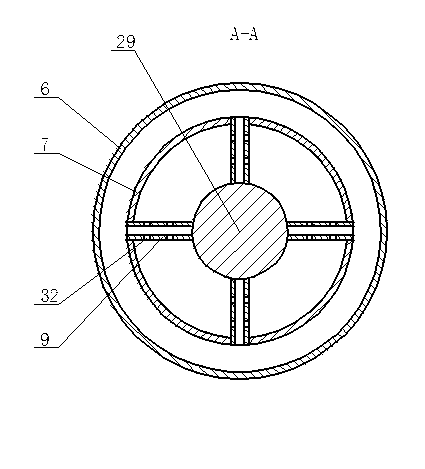

[0007] The device for purifying and recovering the primary high-temperature flue gas of the converter by directly calcining lime according to the present invention includes a converter 1, the converter 1 is connected to the vaporization cooling flue 2 through the movable hood 36, and the vaporization cooling flue 2 is connected to the heat storage through the recovery pipe 4 The regenerator chamber 5 is connected to one end of the intake pipe 3, and the other end of the intake pipe 3 is connected to the flue gas distribution pipe 31. The flue gas distribution pipe 31 is an annular pipe installed on the lower part of the outer wall of the lime kiln shell 7. Lime The top of the kiln shell 7 is provided with a feed port 8, the bottom of the lime kiln shell 7 is provided with a discharge port 28, and a discharge valve 12 is provided at the discharge port 28, and an annular flue gas collection pipe 6 is installed on the upper part of the outer wall of the lime kiln shell 7. Lime The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com