Method for comprehensively utilizing degreased rice bran

A technology for defatting rice bran and rice bran protein, applied in the field of comprehensive utilization of resources, can solve the problems of reducing the value-added rate of rice bran resources, deep separation of main components of rice bran, etc., and achieves the advantages of improving utilization rate and economic value, high comprehensive utilization rate and large economic benefit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

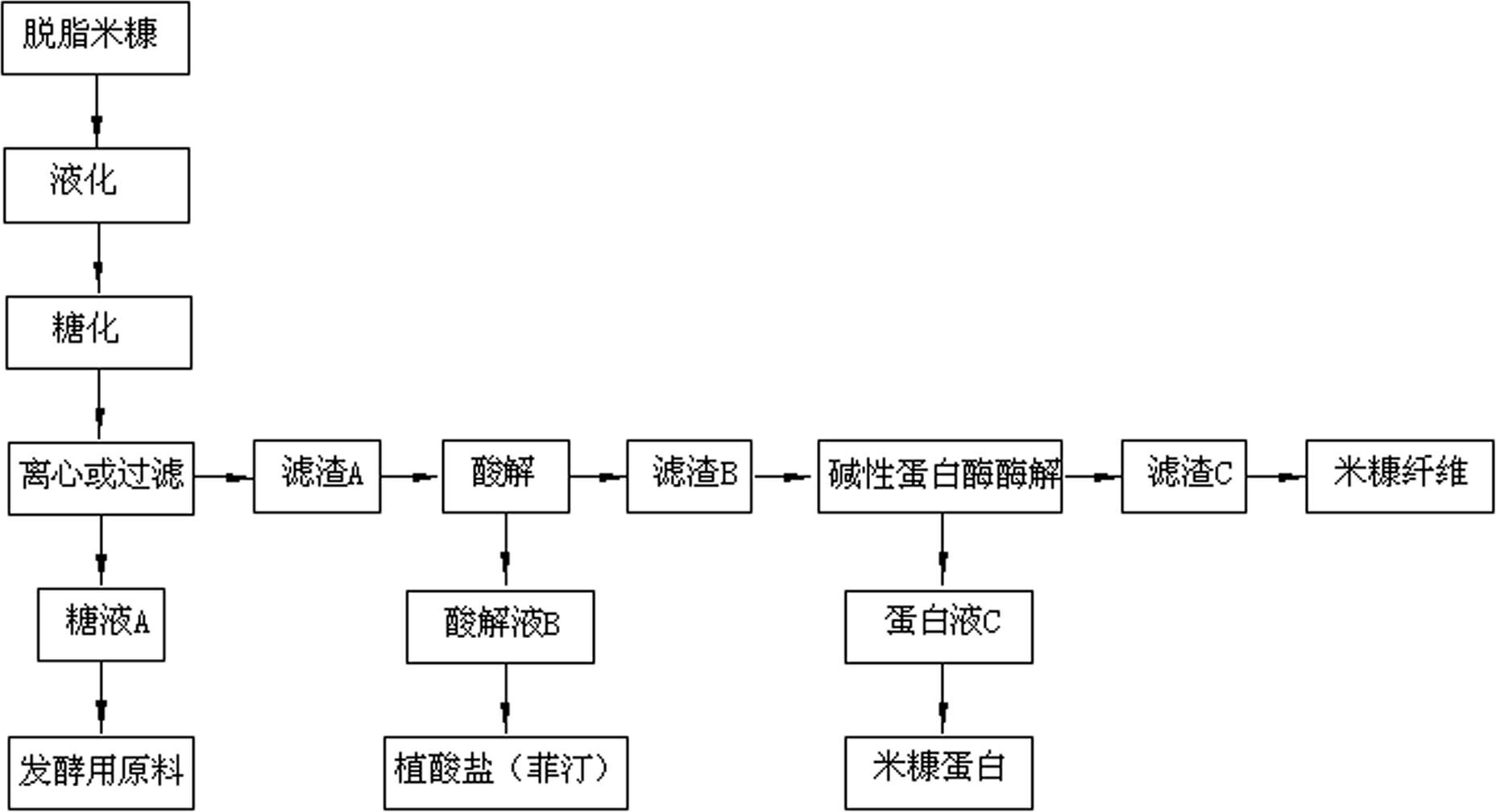

Image

Examples

Embodiment 1

[0035] 1) Add 5 times the weight of water (250g) and 1% (0.5g) liquefied enzyme to 50g defatted rice bran, stir and react at 90°C until the iodine test is complete, cool to 60°C, adjust the pH value to 4.5, add 2 % (1g) glucoamylase, saccharified for 2h, filtered to obtain residue A and supernatant A.

[0036] The supernatant A is directly used as the medium for production and fermentation: the supernatant A is adjusted to pH 5.5 with ammonia water, and then sterilized by high-temperature steam at 121°C for 15 minutes. After cooling, it is inserted into Clostridium acetobutylicum for anaerobic fermentation. 2% of the volume of the culture medium, the fermentation temperature is 32°C, and the fermentation time is 72 hours. After fermentation, a fermentation broth with a solvent content of 16.5g / L can be obtained. The ratio of acetone, butanol, and ethanol is about 3:6:1. Distillation separates acetone, butanol and ethanol.

[0037] 2) Add residue A to 5 times its weight of wat...

Embodiment 2

[0041]1) Add 5 times the weight of water and 1% liquefied enzyme to 50g defatted rice bran, stir and react at 90°C until the iodine test is complete, filter to obtain residue A and supernatant A, supernatant A is directly used for production fermentation Substratum, obtain biochemical products acetone, butanol and ethanol through fermentation according to the method of embodiment 1;

[0042] 2) Add residue A to 5 times the weight of water, adjust the pH value to 3.9, stir and react at 60°C for 5 hours, filter to obtain residue B and supernatant, wash residue B with water, filter to obtain supernatant and residue, and apply twice The supernatants were combined as supernatant B, and the pH was adjusted to 4.5 with 10% calcium hydroxide solution, and then adjusted to 9.0 with 10% ammonia water, filtered, and the obtained filter cake was washed with water for 3 times, and then dried to obtain phytate products 3.15g.

[0043] 3) Add 5 times the weight of water to the residue B, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com