High-concentration waste water anaerobic fermentation device capable of realizing gas by-pass split-flow

A high-concentration wastewater and anaerobic fermentation technology, which is applied in the field of fermentation equipment and high-concentration wastewater anaerobic fermentation equipment, can solve the problem of poor treatment effect of anaerobic fermentation wastewater, decreased separation efficiency of three-phase separators, and influence on the concentration of anaerobic microorganisms, etc. problems, to achieve the effect of reducing the entrainment of sludge particles, improving the reaction effect, and maintaining the concentration of sludge particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

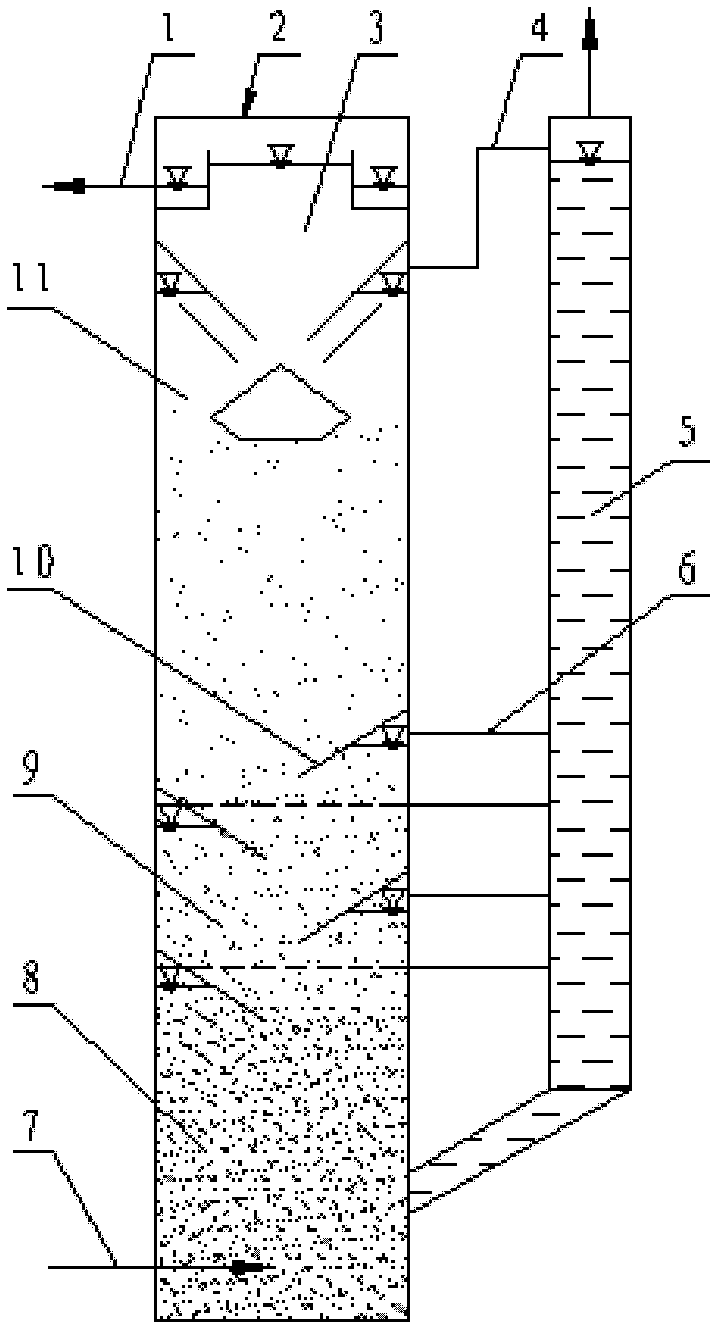

[0023] A high-concentration wastewater anaerobic fermentation device capable of realizing gas bypass diversion, including a reactor 11 mainly composed of a shell 2 and a three-phase separator 3, the three-phase separator is installed at the upper end of the shell, and the shell The lower part is provided with water inlet 7, the upper part of the shell is provided with water outlet 1, and the anaerobic sludge containing anaerobic microorganisms is placed in the reactor shell, and the anaerobic sludge forms a granular sludge layer 8 in the lower part of the shell. Form flocculent sludge layer 9 in the middle part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com