Pompon bismuthous sulfide and preparation method thereof

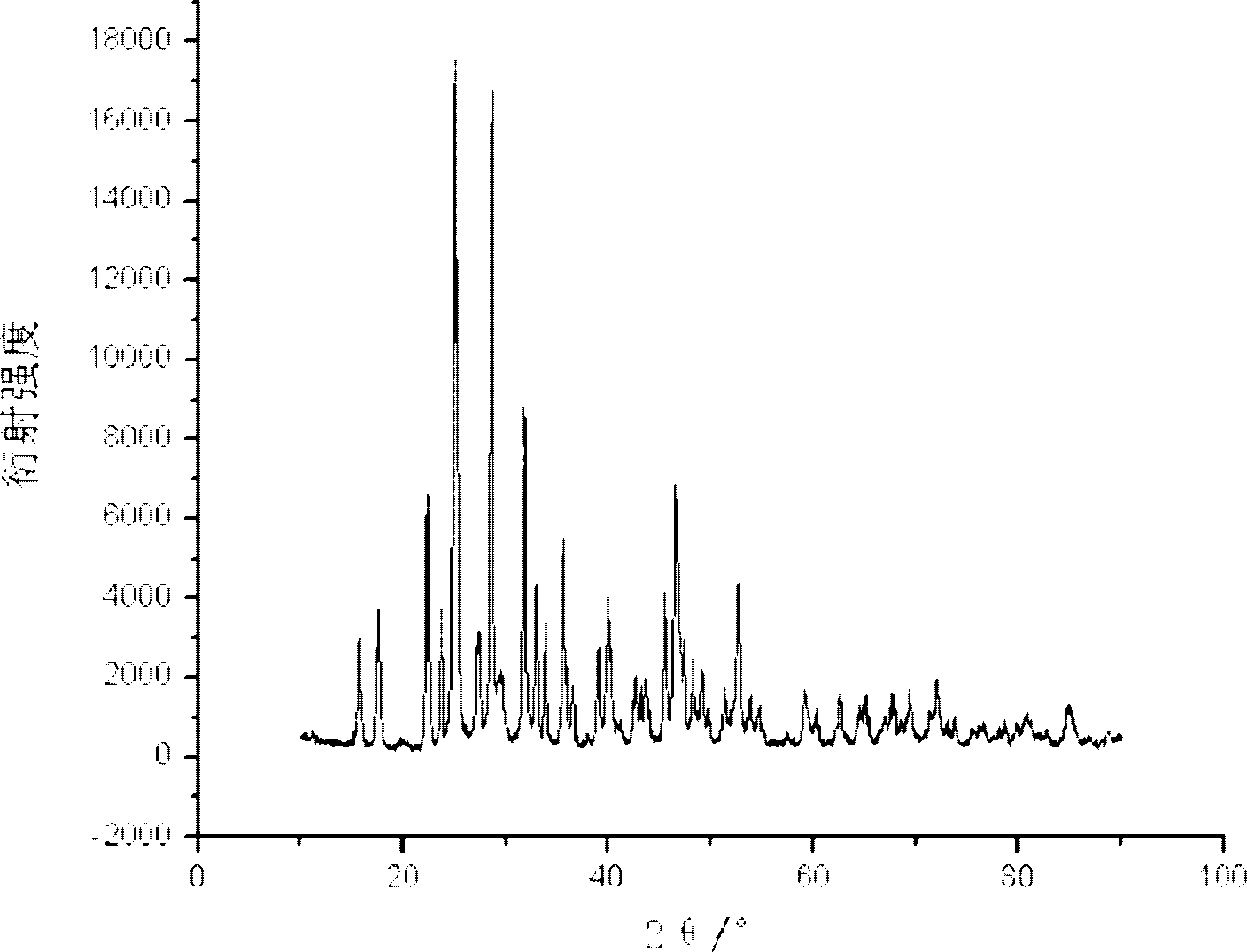

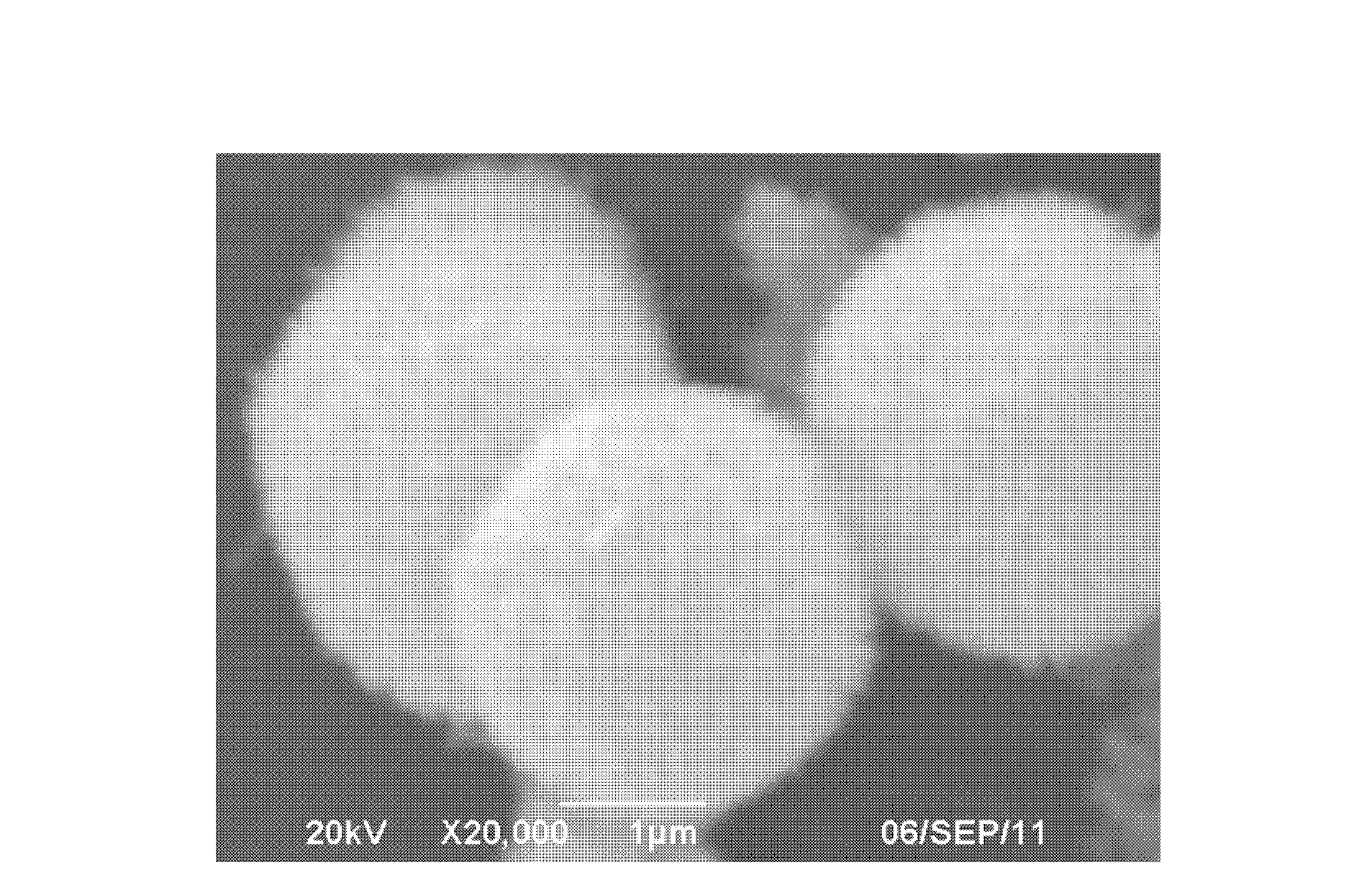

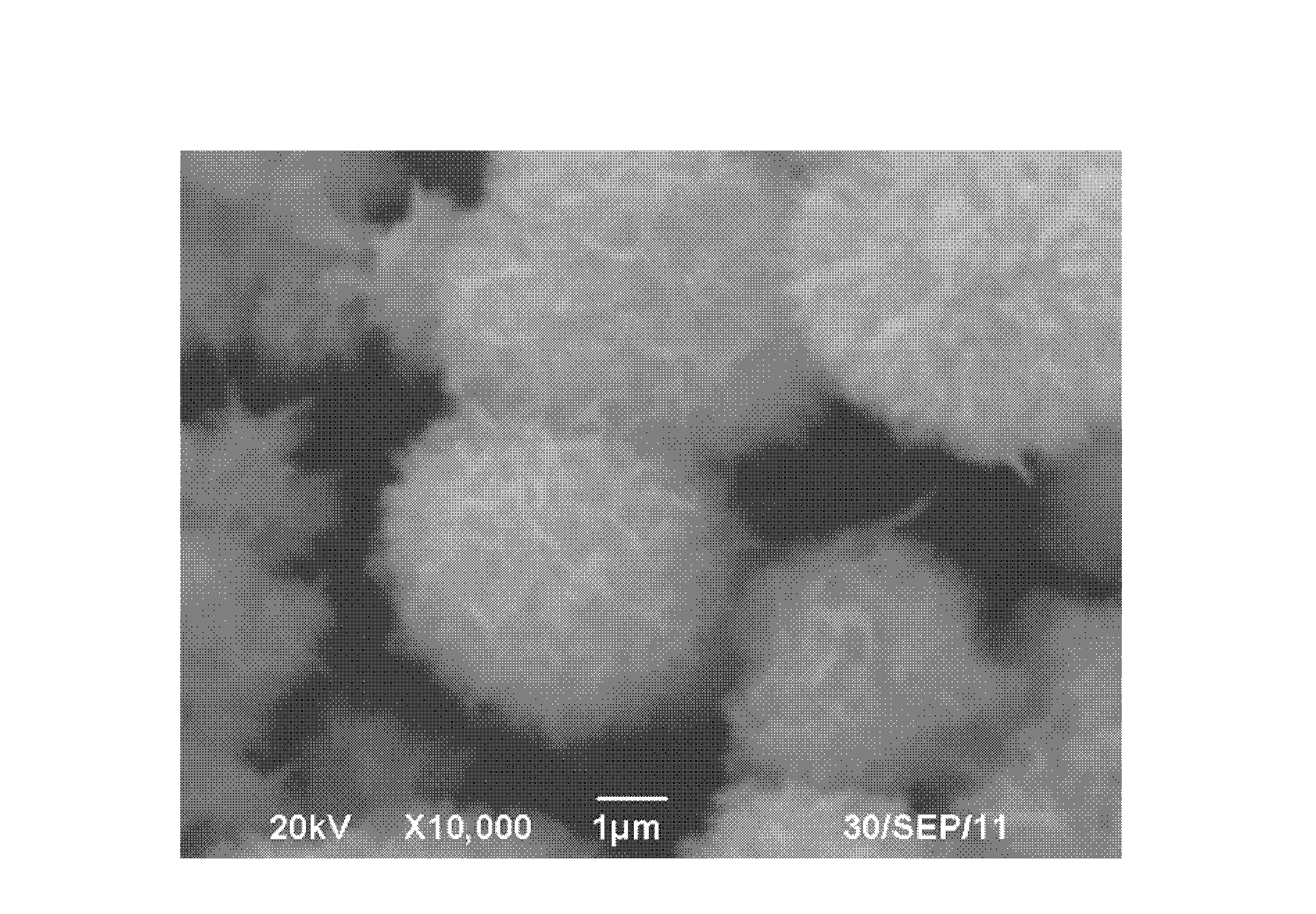

A technology of bismuth trisulfide and bismuth sulfide, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve problems such as difficult bismuth sulfide materials, and achieve the effects of large specific surface area, good crystallization and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] First, bismuth nitrate was dissolved in DMF to prepare a 0.2mol / L solution; and carboxylated PPV was dissolved in methanol or water to prepare a 0.2mol / L solution; 1 volume ratio mixed, stirred at room temperature for 30 minutes to obtain a mixed solution; thioacetamide was dissolved in methanol to prepare a 0.2mol / L solution, according to the molar ratio Bi:S=3:2, added to the mixed solution obtained above After stirring evenly at room temperature, place it in a hydrothermal kettle and heat at a constant temperature of 120°C for 12 hours; take out the hydrothermal kettle, cool it to room temperature, and centrifuge at a speed of 5000 rpm to obtain a black solid, then Repeatedly wash with deionized water and ethanol until the centrifuged liquid is colorless, clear and transparent; then extract the centrifuged solid with ethanol, and finally place the solid obtained by ethanol extraction in a vacuum drying oven at 60°C Dry to obtain the product fluffy bismuth sulfide mat...

Embodiment 2

[0017] First, the Bi(NO 3 ) 3 ·5H 2 O was dissolved in DMF to prepare a 2mol / L solution; and the carboxylated PPV was dissolved in methanol or water to prepare a 0.001mol / L solution; the two solutions configured above were mixed in a volume ratio of 1:10, Stir at room temperature for 30 minutes to obtain a mixed solution; then dissolve thiourea in methanol to prepare a 0.01mol / L solution, add it to the mixed solution obtained above according to the molar ratio Bi:S=3:2, and stir evenly at room temperature After that, put it in a hydrothermal kettle and heat at a constant temperature of 80°C for 24 hours; take out the hydrothermal kettle, cool it to room temperature, and centrifuge at a speed of 8000 rpm to obtain a black solid, and then use deionized water to obtain a black solid. Repeated washing with ethanol until the centrifuged liquid is colorless, clear and transparent, and the solid separated by centrifugation; then the solid separated by centrifugation is extracted wi...

Embodiment 3

[0020] First, the Bi(NO 3 ) 3 ·5H 2 O was dissolved in DMF to prepare a 0.01mol / L solution; and the carboxylated PPV was dissolved in methanol or water to prepare a 2mol / L solution; the two solutions configured above were mixed in a volume ratio of 1:0.01, Stir at room temperature for 30 minutes to obtain a mixed solution; dissolve thiourea in methanol to prepare a 0.2mol / L solution, add it to the mixed solution obtained above according to the molar ratio Bi:S=3:2, and stir evenly at room temperature , placed in a hydrothermal kettle, and heated at a constant temperature of 160°C for 8 hours; the hydrothermal kettle was taken out, cooled to room temperature, and centrifuged at a speed of 3000 rpm to obtain a black solid, and then deionized water and ethanol were used respectively Alternately and repeatedly washed until the centrifuged liquid is colorless, clear and transparent, the solid separated by centrifugation; then the solid separated by centrifugation is extracted wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com