Automatic filament charging machine

An automatic and wire machine technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of automatic wire unloading machine running errors, affecting the normal operation of the storage gate assembly, etc., to save installation space, improve work reliability, Wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

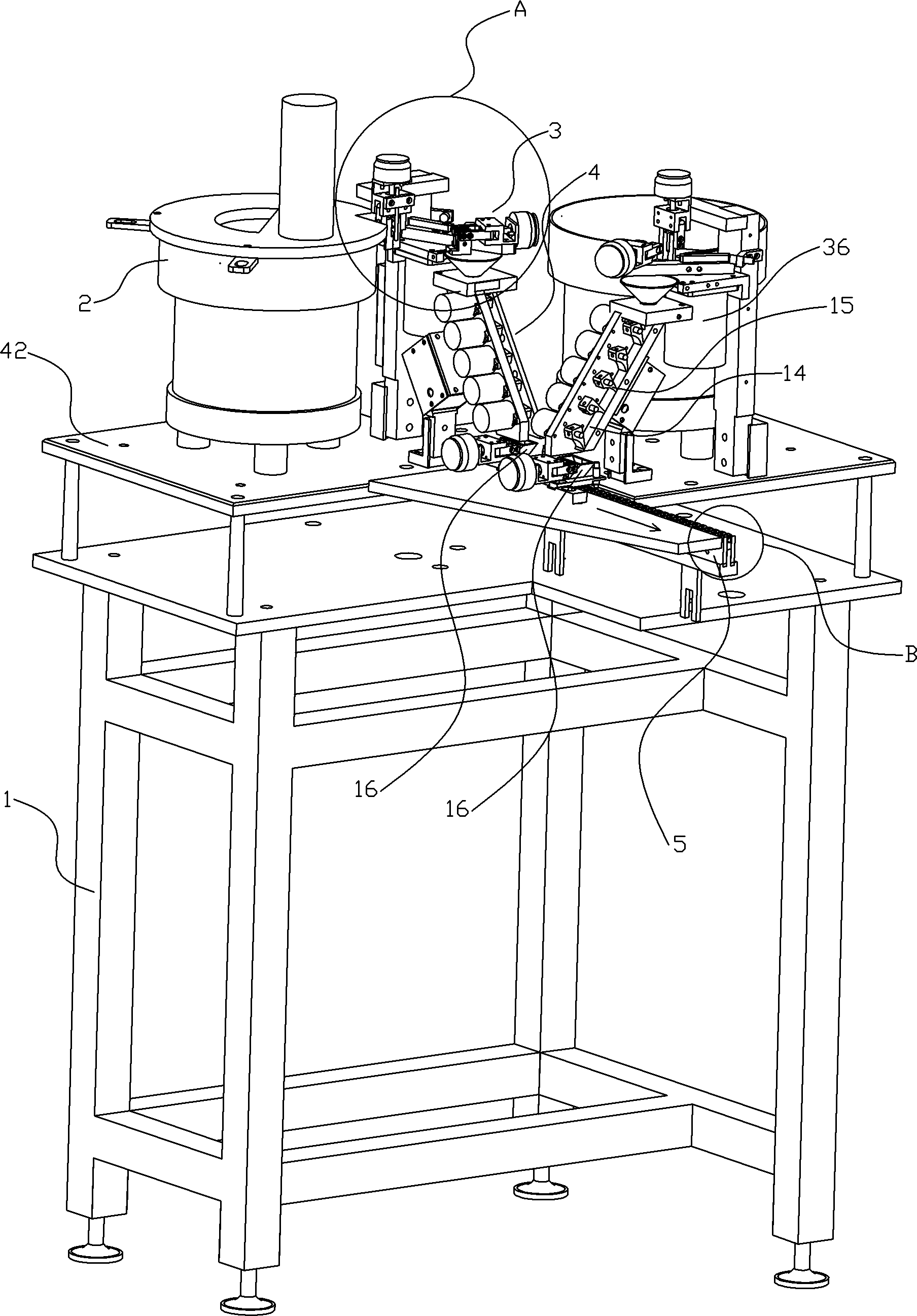

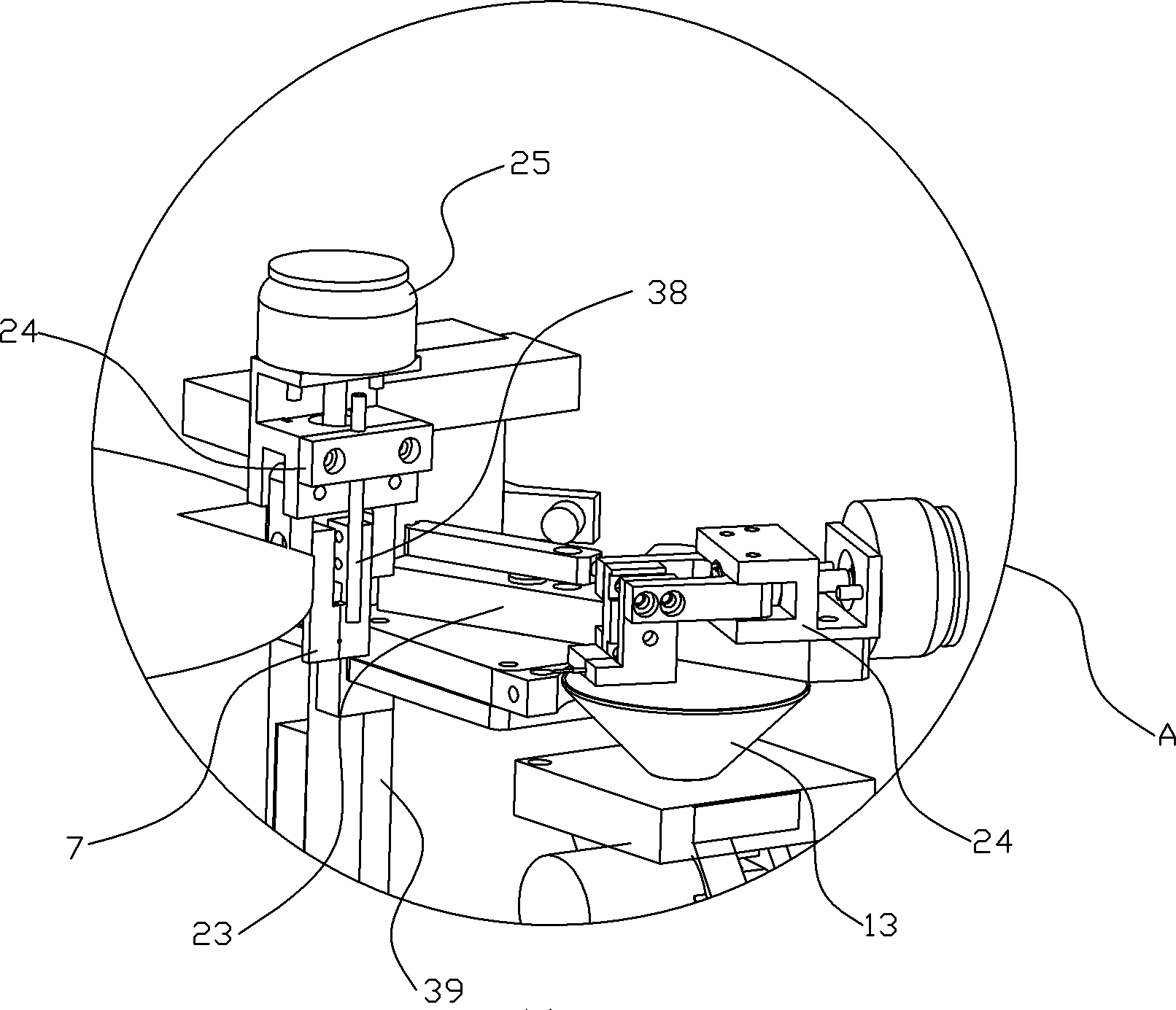

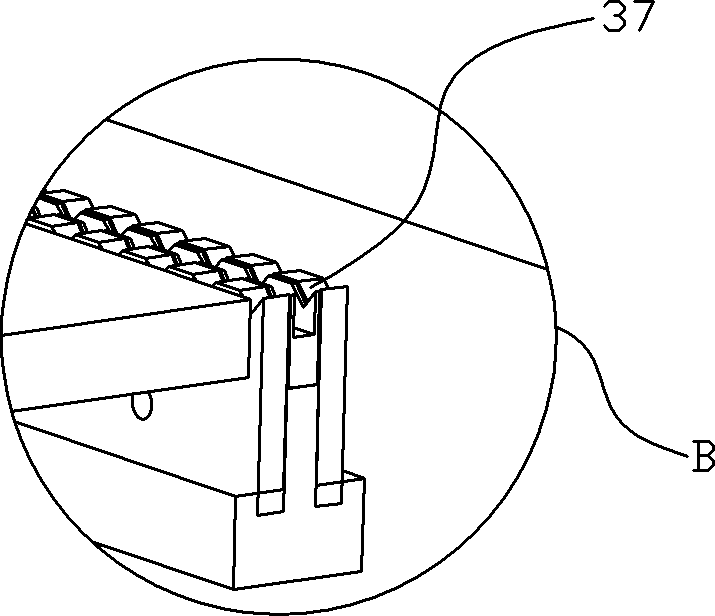

[0029] Such as Figure 1-12 As shown, the automatic wire loading machine includes a frame 1, on which a mounting platform 42 is provided, and a feeding track 5 with a V-shaped feeding groove 37, a controller (not shown in the figure), and two groups of the same structure of the filament conveying device, each group of filament conveying devices includes a vibrating hopper 2, a filament conveying assembly 3 and a storage gate assembly 4 that sequentially transmits and conveys the filament, and the output end of the storage gate assembly 4 is located directly above the feeding track 5 Arranged in sequence along the forward direction of the feeding track.

[0030] The storage gate assembly 4 includes a hopper 13, a slanted material guide trough 14 located at the lower end of the hopper and open at both ends of the upper and lower ends, a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com