Automatic positioning system and method

An automatic positioning and control system technology, applied in the direction of metal processing, etc., can solve the problems of troublesome installation of workpieces, high difficulty of debugging, increased cost and difficulty of silk screen printing, etc., to achieve the effect of reducing labor intensity, ensuring processing accuracy, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

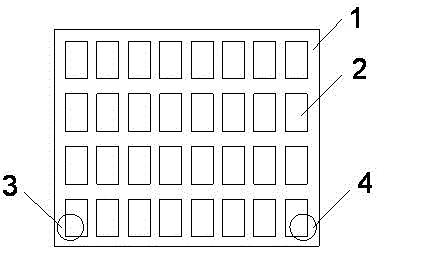

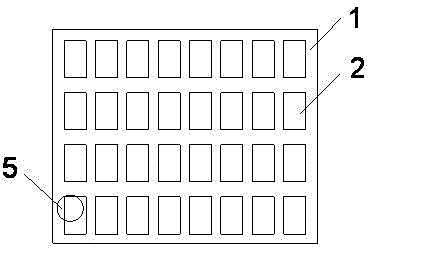

[0028] An automatic positioning system for cutting screen printing plates, including:

[0029] The body is used to set the various components of the automatic positioning system;

[0030] CCD camera, set in the machine body, is used to take images of the silk screen printing plate;

[0031] The lighting system is set inside the body and is used to provide the screen printing plate with the light source required for taking pictures and imaging;

[0032] The workbench, set under the lighting system, is used to adjust the angle deviation and position deviation of the screen printing plate;

[0033] Computer control system, connected with CCD camera, is used to analyze the screen printing plate im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com