Self-cleaning grinding and polishing tool

A self-cleaning, grinding and polishing technology, which is applied in manufacturing tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems such as the overflow of grinding and polishing liquid from grinding and polishing tools and the self-cleaning of grinding and throwing chips. Achieve the effect of avoiding hydrolysis damage, easy application and saving cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

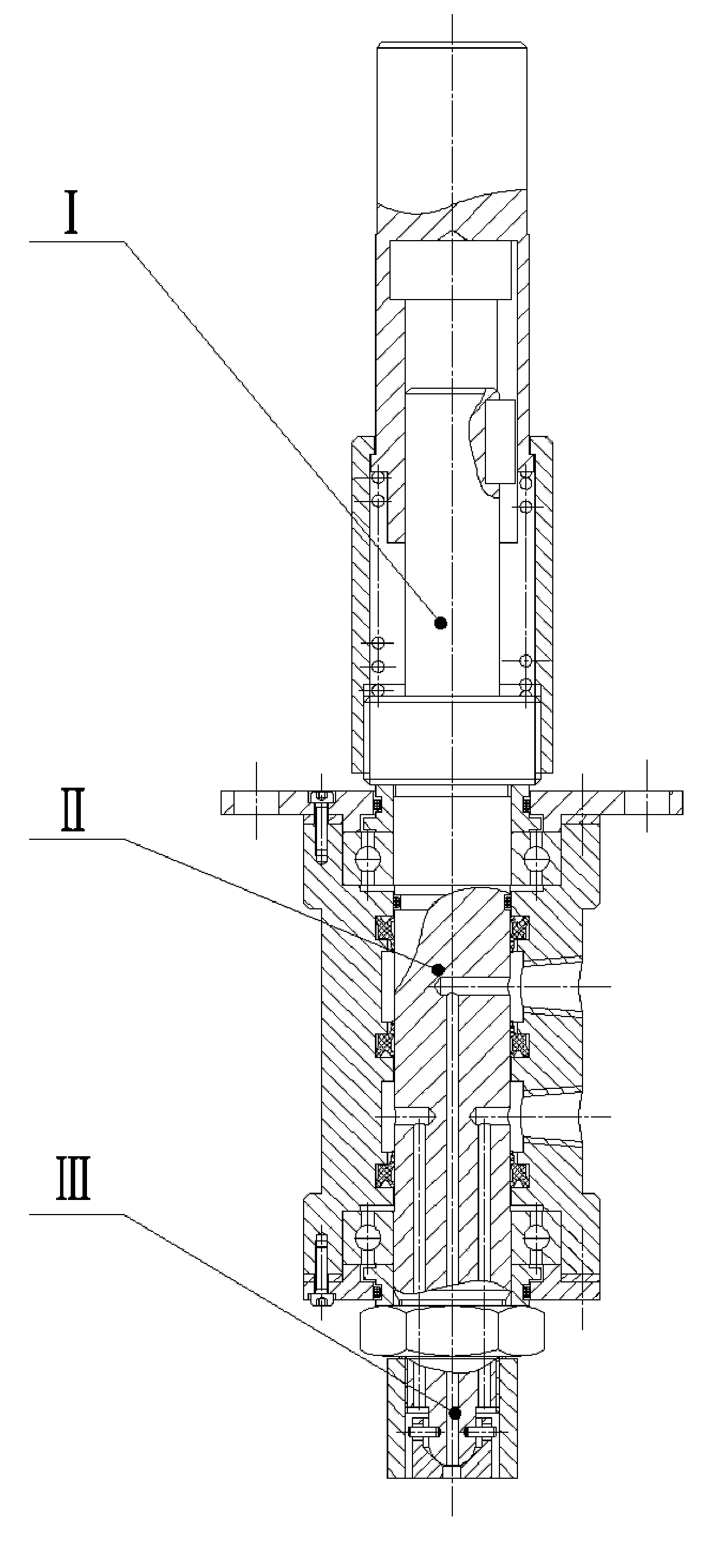

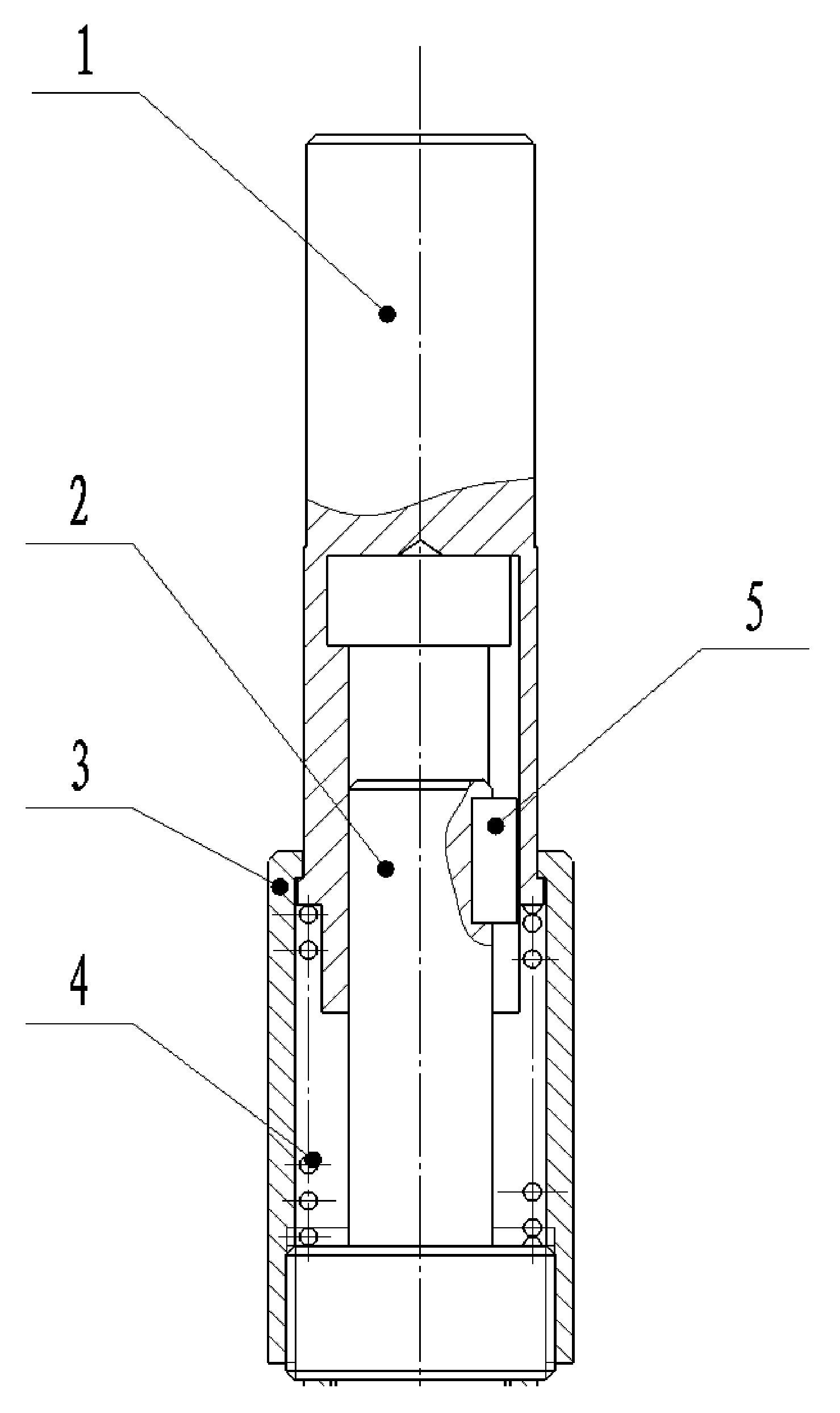

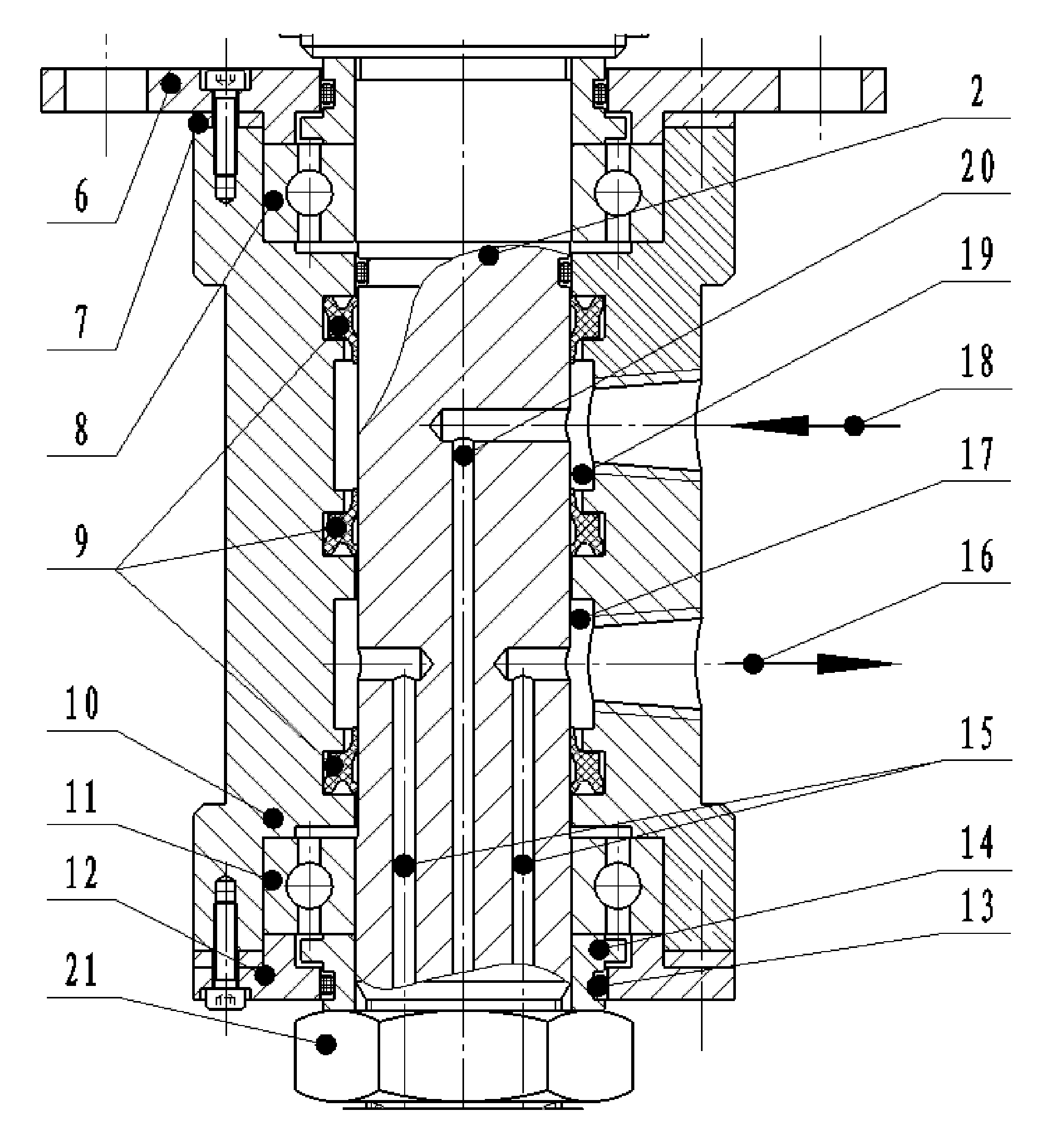

[0024] The structure of the device is as Figure 1-Figure 4 shown. The device consists of a pressurizing unit I, a liquid supply and cleaning unit II and a grinding and polishing unit III.

[0025] Pressurization: When working, first connect the clamping rod 1 to the rotating spindle of the machine tool, and the housing 10 is fixed through the flange hole on the upper end cover 6 so that it cannot rotate; select a spring with appropriate stiffness according to the grinding and polishing pressure; control the screw sleeve Adjust the pre-compression amount of the spring 4; stick the polishing pad at the bottom of the grinding and polishing head 23, and contact with the workpiece to be ground and polished; control the vertical feed of the machine tool, the clamping rod 1 and the central axis 2 move relatively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com