Special hydraulic tool for installation and disassembly of cantilever type impeller

A cantilever type, impeller technology, applied in the components, manufacturing tools, metal processing, etc. of the pumping device for elastic fluid, to achieve the effect of large axial force, simple structure, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

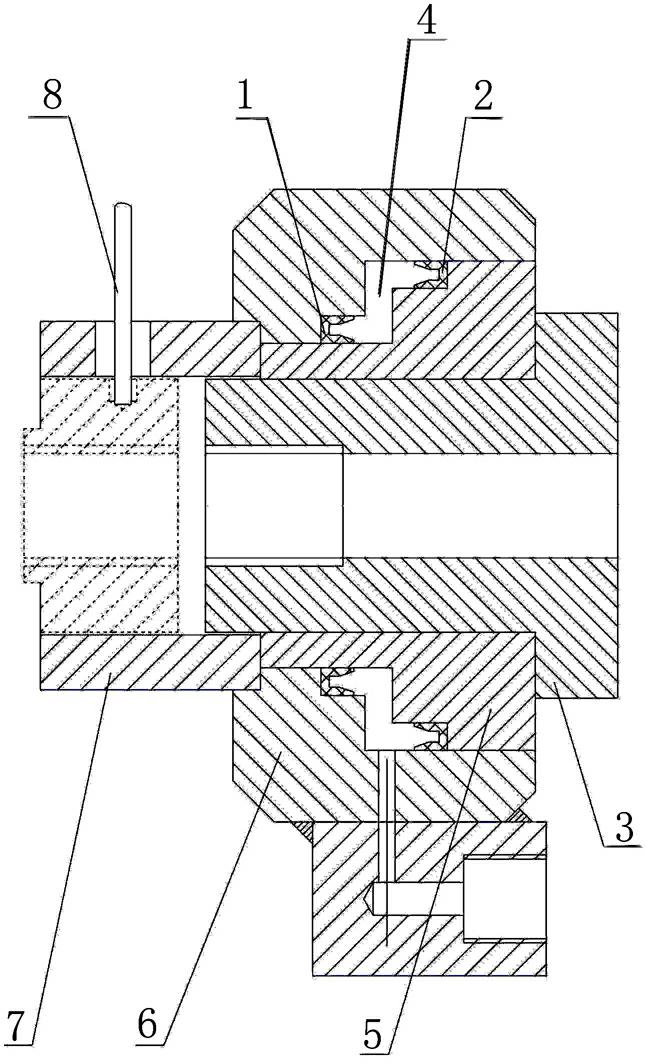

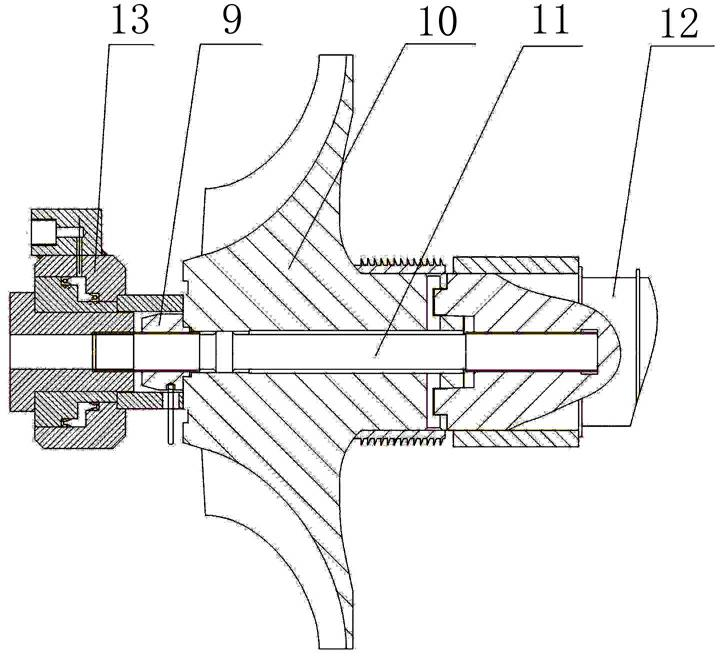

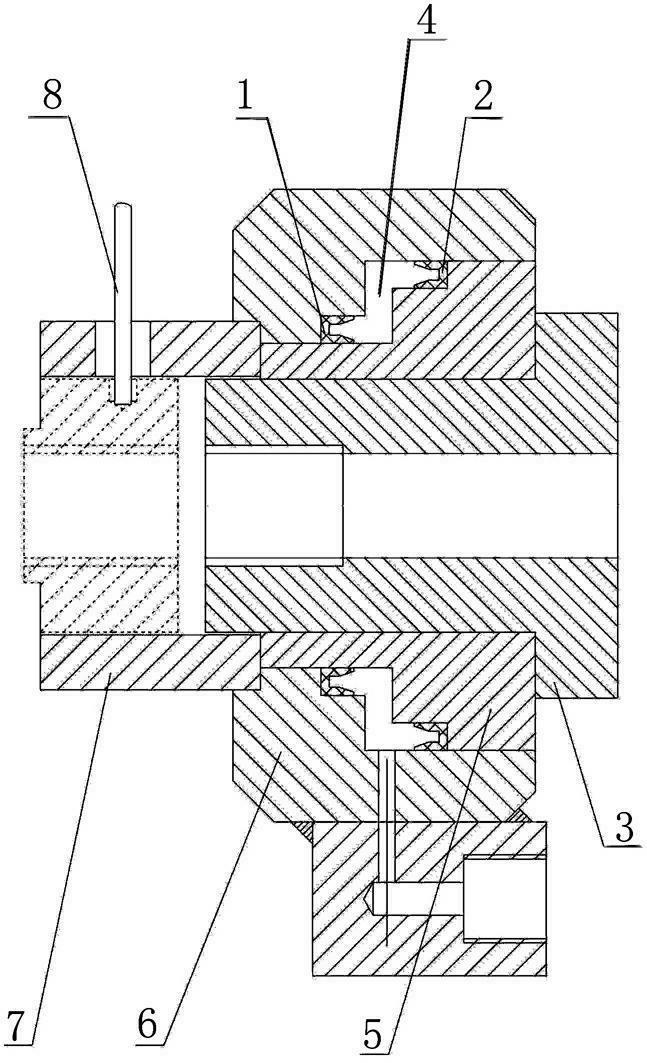

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention mainly includes an adjusting nut 3 that can be connected with the center bolt 11 of the impeller. The adjusting nut 3 is sleeved with an inner cylinder liner 5 and an outer cylinder liner 6 that cooperate with each other, and the inner cylinder liner 5 and the outer cylinder liner An oil pressure cavity 4 communicating with the peripheral hydraulic pump is formed between the cylinder liners 6; a sleeve 7 that can withstand the end wall of the impeller 10 is screwed on the side where the adjusting nut is connected to the central bolt 11.

[0010] In the hydraulic cavity 4, an inner sealing ring 1 and an outer sealing ring 2 are respectively provided at the connecting seams of the two ends of the inner cylinder liner 5 and the outer cylinder liner 6; The driving rod 8 that cooperates with the locking nut 9 of the impeller 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com