Crystallizer for MW (megawatt)-scale wind power torsion shaft electroslag casting

A technology of electroslag casting and mold, applied in the field of casting molds, can solve the problems of complex shape, restricting development, complex structure of mold for electroslag casting, etc., and achieves the effect of high positioning accuracy and no large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Determine the mold parting scheme, the increase in the transitional cavity between the crank mold and the conventional shaft mold:

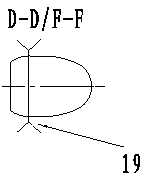

[0056] First, design the parting scheme of the wind power torsion axis crystallizer according to the part drawing (see figure 2 ), the splitting scheme determines the success or failure of the crystallizer. According to the number of cranks, the torsion axis crystallizer is divided into 5 sections and 10 split-type combined crystallizers. The parting position 19 is divided into section I21, section II22, section III23, section IV24 and section V25. Secondly, a transition cavity is designed at the thickest part of the crank arm. The size of the transition cavity is determined by the uniform seamless transition time between the power at the thickest part of the crank arm and the normal shaft power. After calculation and verification, it is finally determined that the uniform seamless transition time is about 1 hour, and then the height ...

Embodiment 2

[0067] 1. Determine the mold parting scheme, the increase in the transitional cavity between the crank mold and the conventional shaft mold:

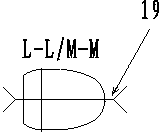

[0068] Design the parting scheme of the wind power torsion axis crystallizer according to the parts drawing (see image 3 ), according to the number of cranks, the torsion axis crystallizer is divided into 5 sections and 10 split-type combined crystallizers, and the type position 19 is divided into section I21, section II22, section III23, section IV24 and section V25. The height of the transition cavity is 150mm, and the increased transition cavity is added to the crank crystallizer with a circular transition.

[0069] 2. Design and manufacture of crystallizer

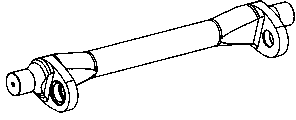

[0070] The crystallizer structure for MW-level wind power torsion shaft electroslag casting is as follows: Figure 4~13 As shown, it is composed of inner cavity type plate 5, water seam plate 11 and water jacket plate 12 through upper flange 1, lower flange 2 and legislative ...

Embodiment 3

[0079] The electroslag casting of the crystallizer provided in Example 1 is used to prepare the torsion shaft for wind power generators, and the process parameters are as follows:

[0080] The composition and weight percentage of the consumable electrode used are shown in Table 1. The electrode size: Φ200×13000 mm.

[0081] Table 1 GS-18NiMoCr3-6 steel consumable electrode composition and weight percentage

[0082] C% Si% Mn% S% P% Cr% Ni% Mo% Fe 0.18 0.43 1.05 0.002 0.018 0.74 0.99 0.61 margin

[0083] Electroslag casting:

[0084] 1) The electroslag casting process is to refine the above-mentioned consumable electrodes and make them into castings. The proportion of slag system is weight percentage: CaF 2 : 60%, Al 2 o 3 : 30%, MgO: 5%, and CaO: 5%. The amount of slag is 3% of the casting weight.

[0085] 2) Ignition method

[0086] The consumable electrode is ignited by solid slag in the crystallizer, and its chemical compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com