Special nodulizer for low-temperature impact resistant and high-ductility nodular cast iron and method for preparing special nodulizer

A technology of nodular cast iron and nodularizers, which is applied in the production of nodularizers for foundry, can solve the problems of unsatisfactory, waste of rare earth resources, high rare earth content, etc., and achieve strong anti-recession ability, saving rare earth resources, and high absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

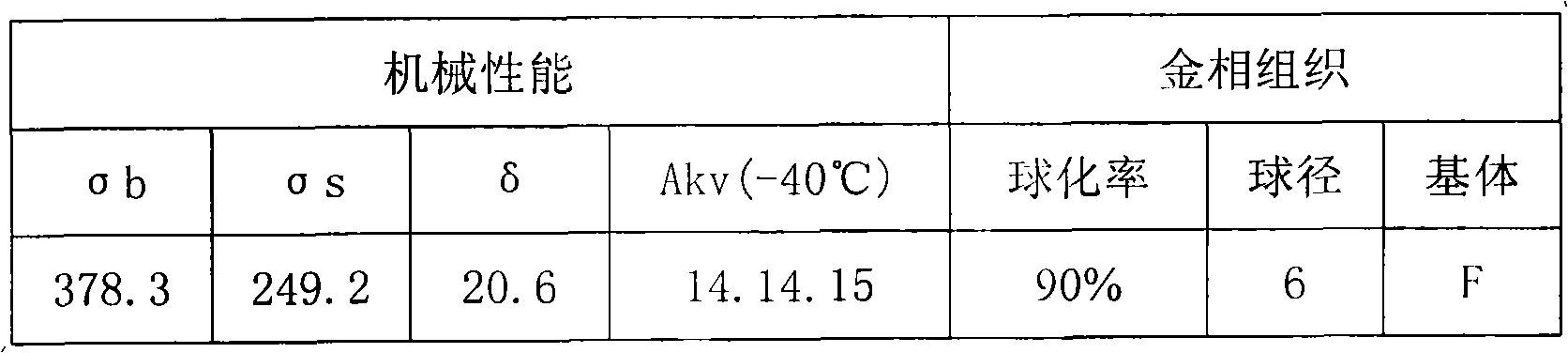

Embodiment 1

[0016] Put 99.4 kg of ferrosilicon and 53 kg of rust-removing scrap steel into the induction furnace for melting, and add slag remover to remove slag during the process. When the temperature is 1430°C, add 5.7 kg of silicon-calcium alloy, rare earth metal (rare earth metal is lanthanum cerium rare earth metal, wherein in terms of mass percentage: lanthanum (La) 30-40%, cerium (Ce) 60-70%) 1.6 kg, and all melted. The entire melting process takes 50 minutes. After melting, inert gas protection is blown into the alloy liquid surface, the alloy temperature is kept at 1450°C, 11 kg of metal magnesium is pressed into the alloy liquid, and kept for 3 minutes, and the melting of metal magnesium is completed. Finally, the ingot is cast at 1350°C under the protection of inert gas. Alloy ingots are crushed in special equipment, and then sieved to obtain alloys that meet the particle size required for use. The weight percent of the chemical composition of the nodulizer thus prepared is...

Embodiment 2

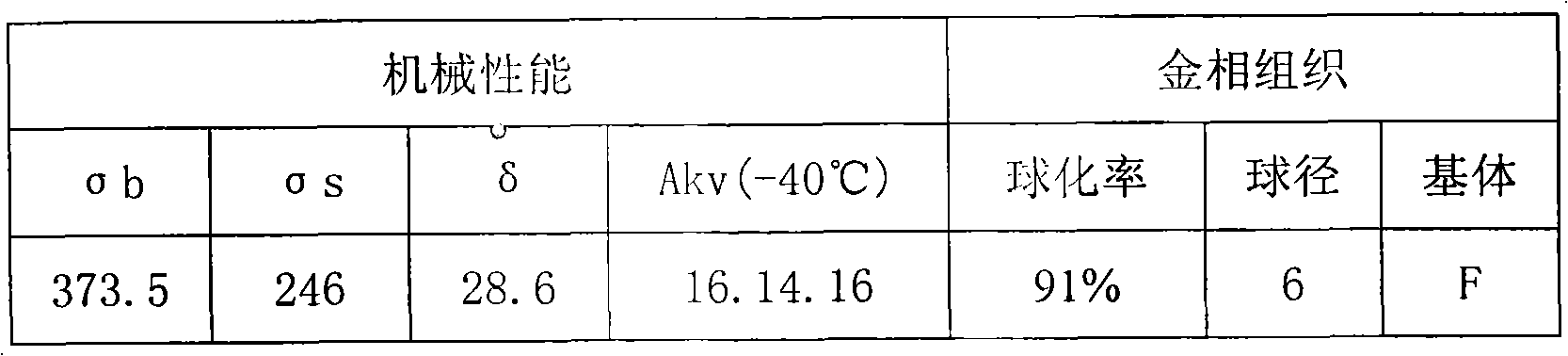

[0021] 198 kg of ferrosilicon and 106 kg of scrap steel are added to the induction furnace for melting, and a slag remover is added in the process to remove slag. When the temperature is 1440°C, add 11.5 kilograms of rare earth metals of silicon-calcium alloy (rare earth metals are lanthanum and cerium rare earth metals, wherein in terms of mass percentage: lanthanum (La) 30-40%, cerium (Ce) 60-70%) 3.3 kg , and all melted. The entire melting process takes 53 minutes. After melting, inert gas protection is blown into the alloy liquid surface, the alloy temperature is kept at 1450° C., 22.2 kg of magnesium metal is pressed into the alloy liquid, and kept for 4 minutes, and the melting of metal magnesium is completed. Finally, it is cast into an ingot at 1340°C under the protection of an inert gas. Alloy ingots are crushed in special equipment, and then sieved to obtain alloys that meet the particle size required for use. The weight percent of the chemical components of the n...

Embodiment 3

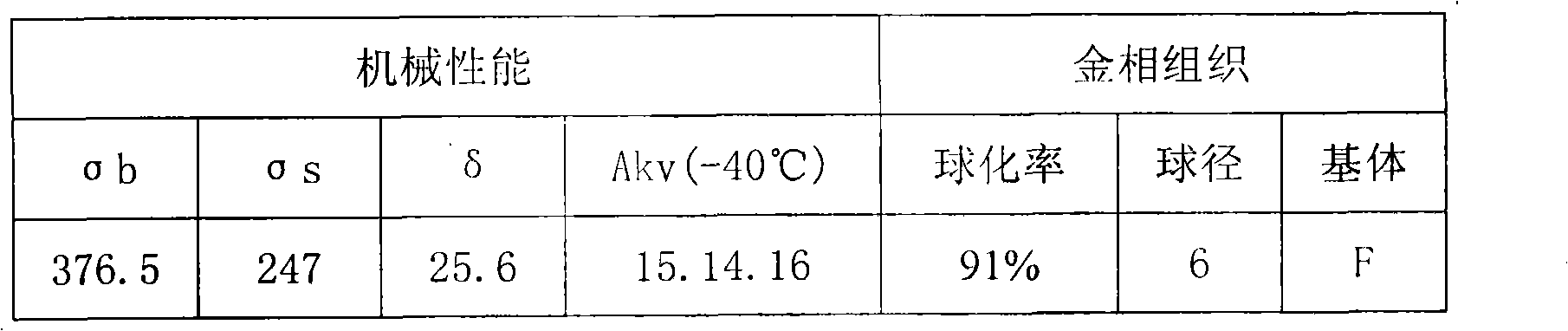

[0025] Add 213 kg of ferrosilicon and 115 kg of rust-removing steel scrap into the induction furnace for melting, and add a slag remover to remove the slag during the process. Add 12.3 kg of silicon-calcium alloy, rare earth metal (rare earth metal is lanthanum cerium rare earth metal, wherein in mass percentage: containing lanthanum (La) 30-40%, cerium (Ce) 60-70%) 3.5 kg, and all melted. The entire melting process takes 60 minutes. After melting, inert gas protection is blown into the alloy liquid surface, the alloy temperature is kept at 1450°C, 24 kg of metal magnesium is pressed into the alloy liquid, and kept for 4 minutes, and the melting of metal magnesium is completed. Finally, the ingot is cast at 1350°C under the protection of inert gas. Alloy ingots are crushed in special equipment, and then sieved to obtain alloys that meet the particle size required for use. The weight percent of the chemical composition of the nodulizer thus prepared is: RE: 0.92%, Mg: 5.98%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com