Method for treating tobacco stems and shreds by ozone

A technology for ozone treatment and shredded tobacco stems, applied in the field of tobacco processing, can solve the problems of difficulty in re-moisturizing tobacco stems, poor re-moisturizing effect of tobacco stems, long treatment period, etc., to reduce harmful components, and to solve woody gas and irritating and harmful components. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

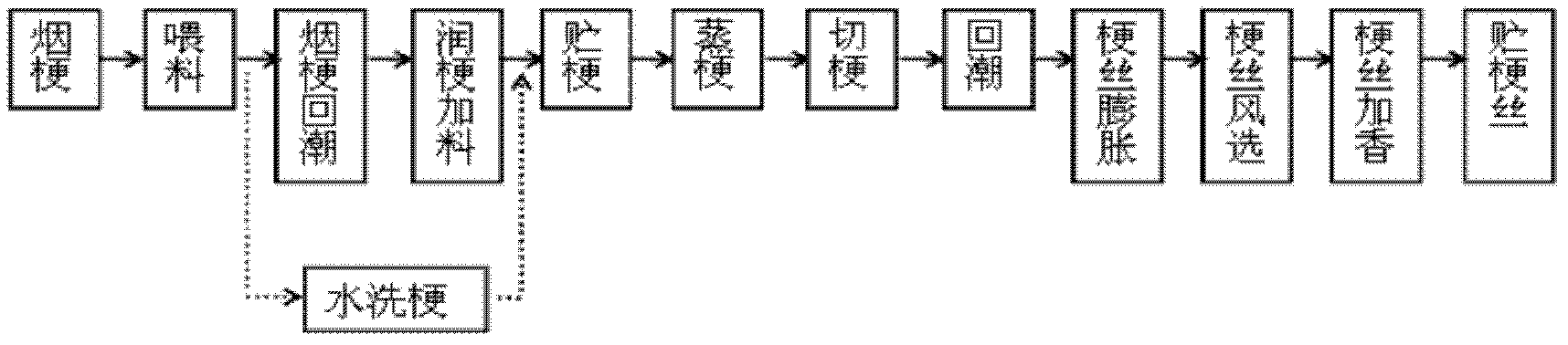

[0041] Embodiment 1: Shredded treatment of tobacco stems

[0042] Take 1000 grams of Yunnan Honghua Dajinyuan Tobacco Leaves in that year according to the conventional tobacco stem treatment method, and carry out the steps of feeding, tobacco stem rehydration, moistening stem feeding, stem storage, steaming stem, stem cutting, dampening, and stem expansion. Silk moisture control is 15% by weight of its expanded tobacco stem.

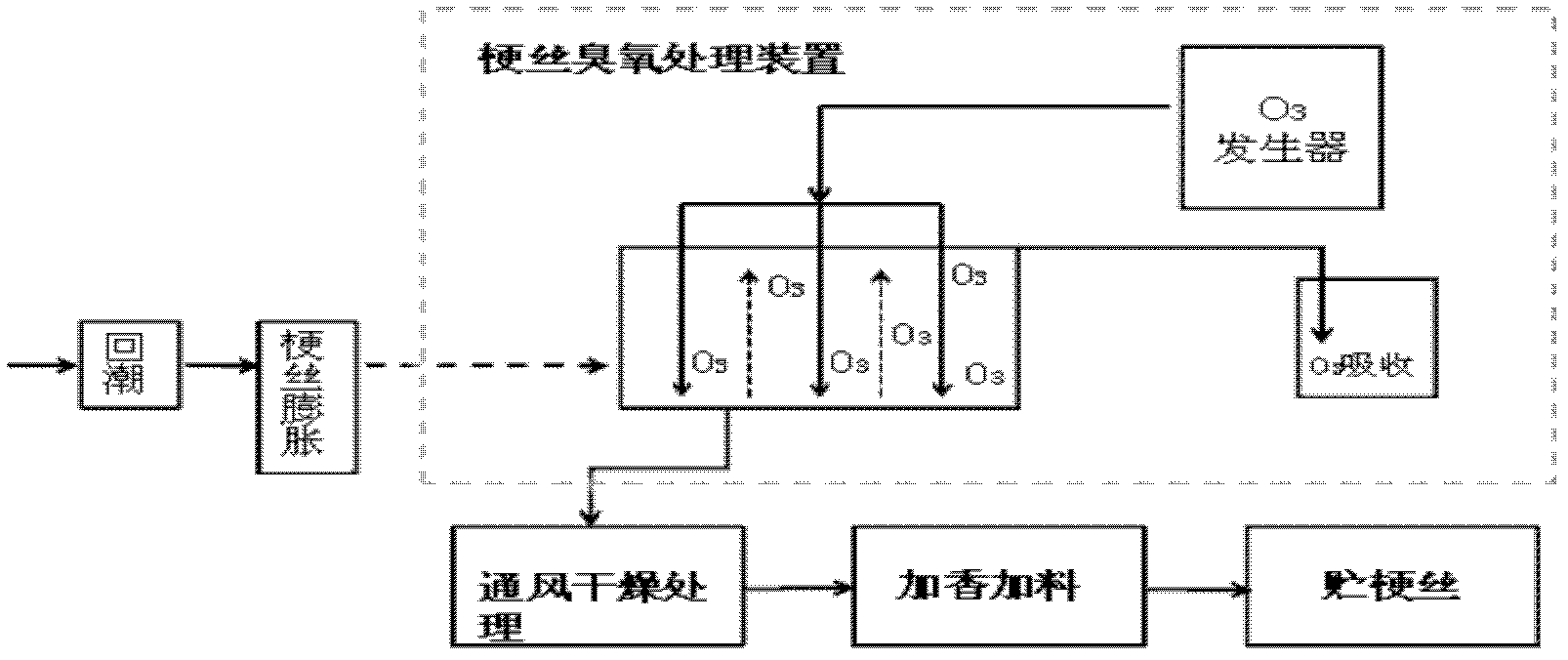

[0043] Then, the expanded shredded tobacco stems were placed in air containing 0.5 mg / L ozone for 10 hours of ozone treatment.

[0044] The ozone-treated cut stems are then subjected to the conventional steps of winnowing the cut stems, flavoring the cut stems and storing the cut stems. Obtain a cut stem treated with ozone, then perform sensory performance evaluation according to the evaluation method described in this specification, and analyze its chemical components and harmful components in smoke according to the analysis method described in this sp...

Embodiment 2

[0046] Embodiment 2: the processing of shredded tobacco stem

[0047] Take 1000 grams of Yunnan Honghua Dajinyuan Tobacco Leaves in that year according to the conventional tobacco stem treatment method, and carry out the steps of feeding, tobacco stem rehydration, moistening stem feeding, stem storage, steaming stem, stem cutting, dampening, and stem expansion. Silk moisture control is 15% by weight of its expanded tobacco stem.

[0048] Then, the expanded shredded tobacco stems were placed in air containing 20 mg / L ozone for 3 hours of ozone treatment.

[0049] The ozone-treated cut stems are then subjected to the conventional steps of winnowing the cut stems, flavoring the cut stems and storing the cut stems. Obtain a cut stem treated with ozone, then perform sensory performance evaluation according to the evaluation method described in this specification, and analyze its chemical components and harmful components in smoke according to the analysis method described in this sp...

Embodiment 3

[0051] Embodiment 3: the processing of shredded tobacco stem

[0052] Take 1000 grams of Yunnan Honghua Dajinyuan Tobacco Leaves in that year according to the conventional tobacco stem treatment method, and carry out the steps of feeding, tobacco stem rehydration, moistening stem feeding, stem storage, steaming stem, stem cutting, dampening, and stem expansion. Silk moisture control is 16% by weight of its expanded tobacco stem.

[0053] Then, the expanded shredded tobacco stems were placed in air containing 60 mg / L ozone for 1 hour of ozone treatment.

[0054] The ozone-treated cut stems are then subjected to the conventional steps of winnowing the cut stems, flavoring the cut stems and storing the cut stems. Obtain a cut stem treated with ozone, then perform sensory performance evaluation according to the evaluation method described in this specification, and analyze its chemical components and harmful components in smoke according to the analysis method described in this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com