90-degree turning mechanism for microwave waveguide pipeline

A microwave waveguide and pipe technology, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of increased processing difficulty, large gradually bent size of the connection, and limited use range of the turning mechanism, so as to increase the processing space and reduce the processing time. Difficulty, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

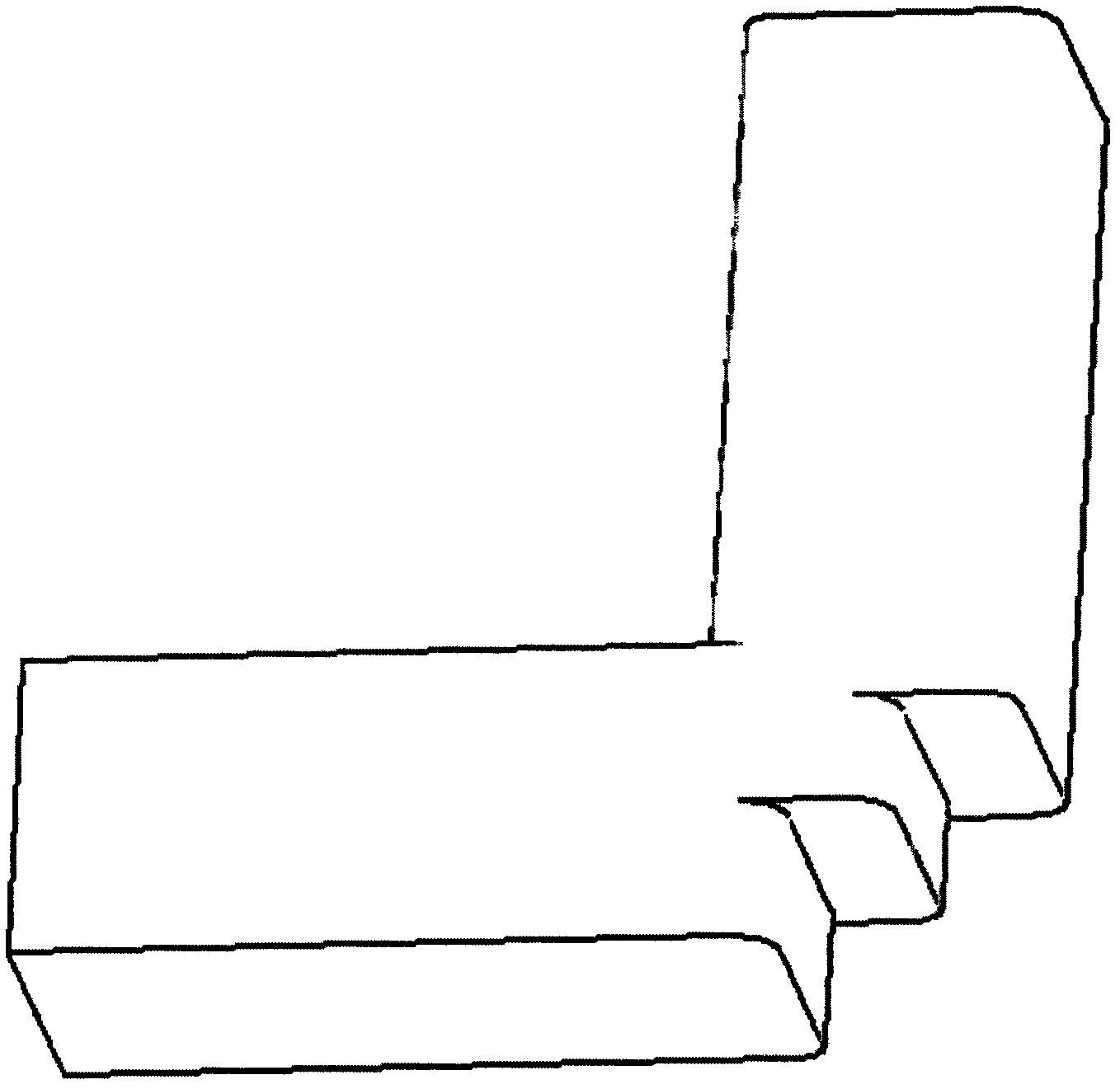

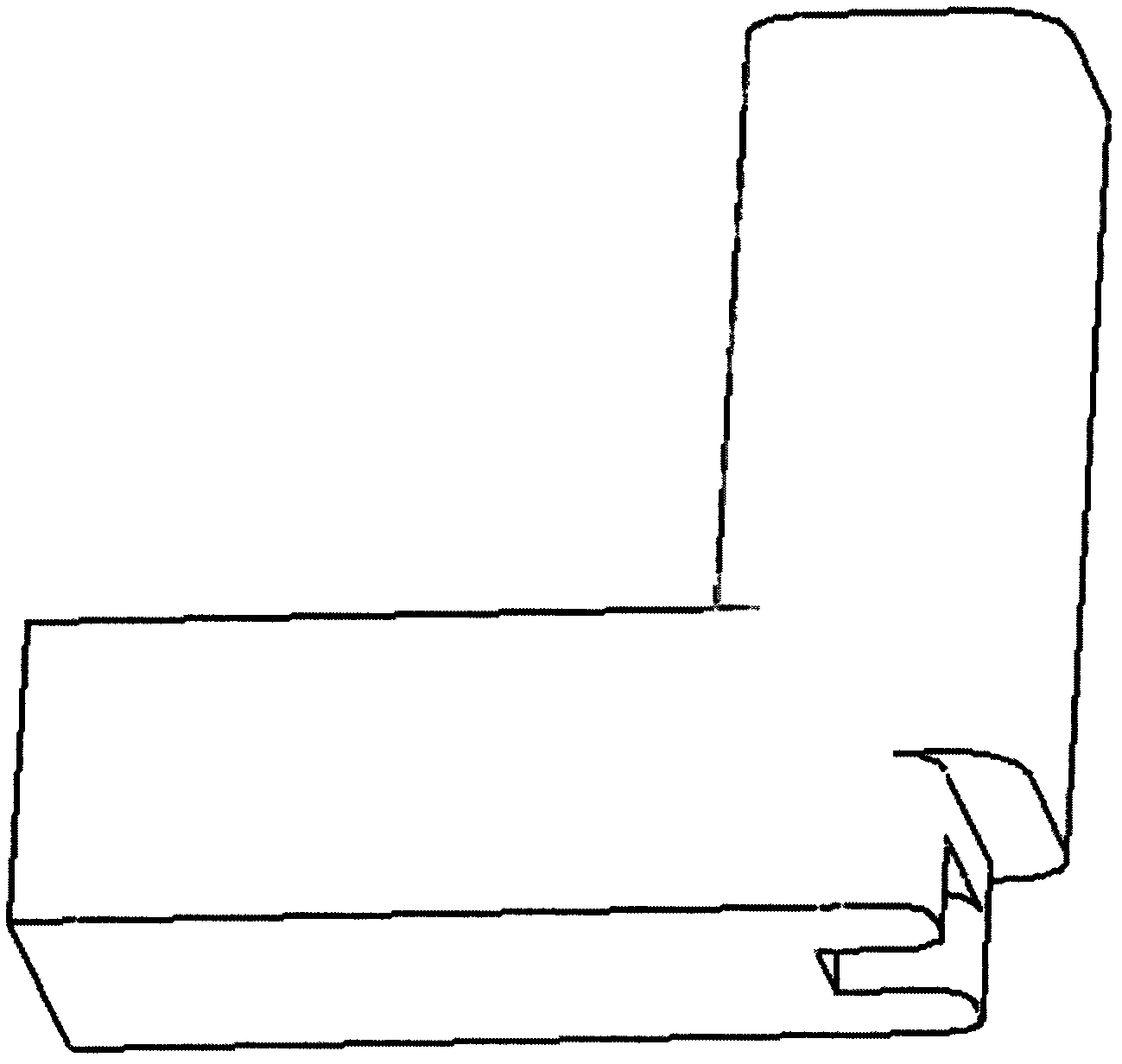

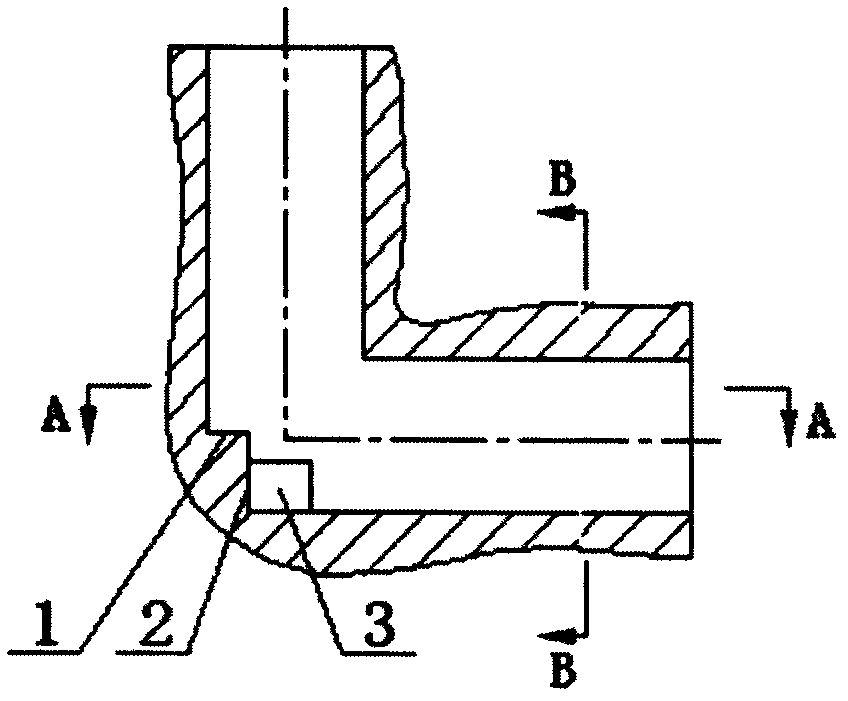

[0014] Such as Figure 2 to Figure 5 As shown, the microwave waveguide pipe 90-degree turning mechanism of the present invention includes a microwave pipe, which is formed by connecting two mutually perpendicular straight pipes. There is a step on the tube wall at the outer corner of the right-angle connection of the microwave tube, and the upper surface 1 and the vertical surface 2 of the step are perpendicular to the tube wall of the microwave tube where it is located. The middle position of the vertical surface 2 of the step is provided with a boss 3 perpendicular to the vertical surface 2, the height of the boss 3 is less than the height of the step, and there is a gap between the two sides of the boss 3 and the wall of the microwave pipeline . In this embodiment, the two sides of the boss 3 and the tube wall of the microwave tube are in a circular arc transition.

[0015] Compared with the turning mechanism composed of multiple steps, the 90-degree turning mechanism of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com