Surface-mounted temperature relay

A temperature relay, mounted technology, applied in the direction of thermal switch components, etc., can solve the problem that the temperature relay cannot meet the demand, achieve good insulation and voltage resistance, improve welding quality, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

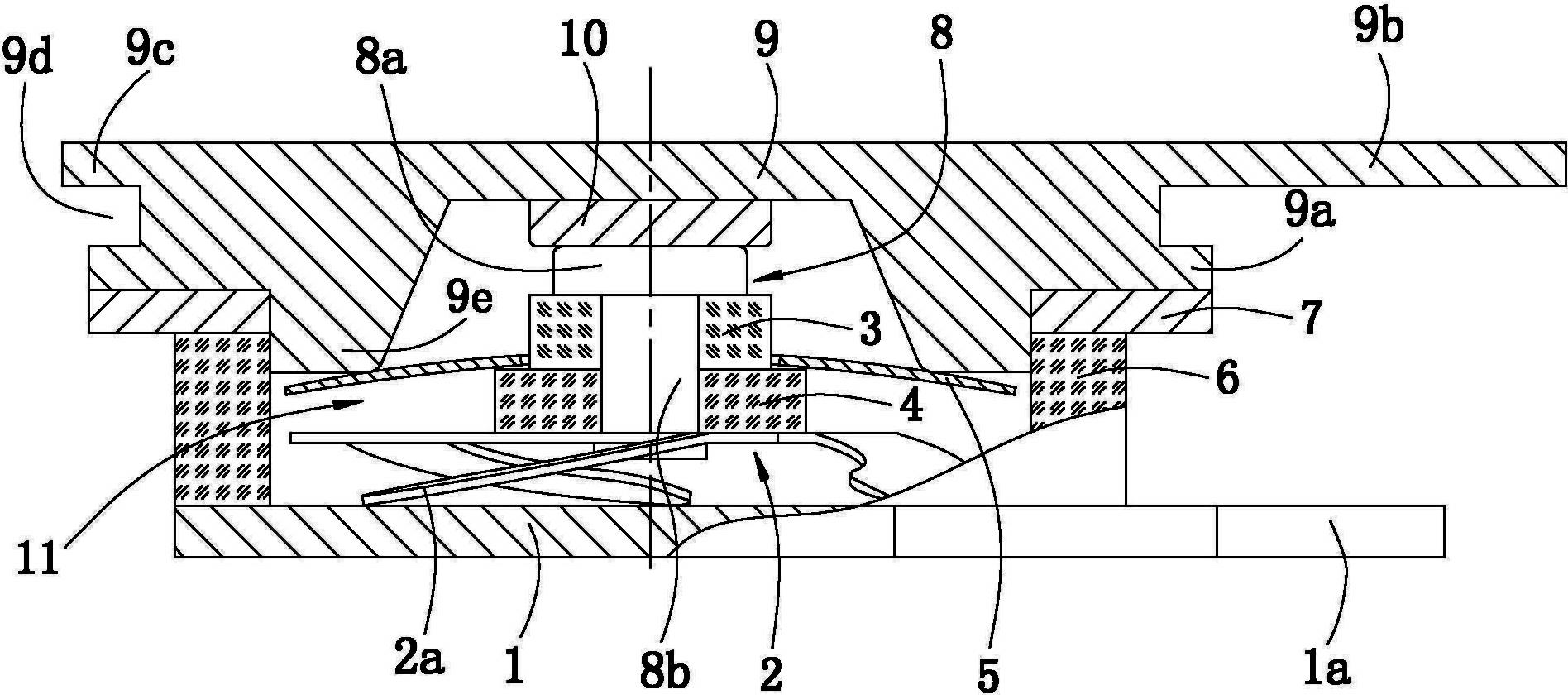

[0024] see figure 1 , figure 2 :

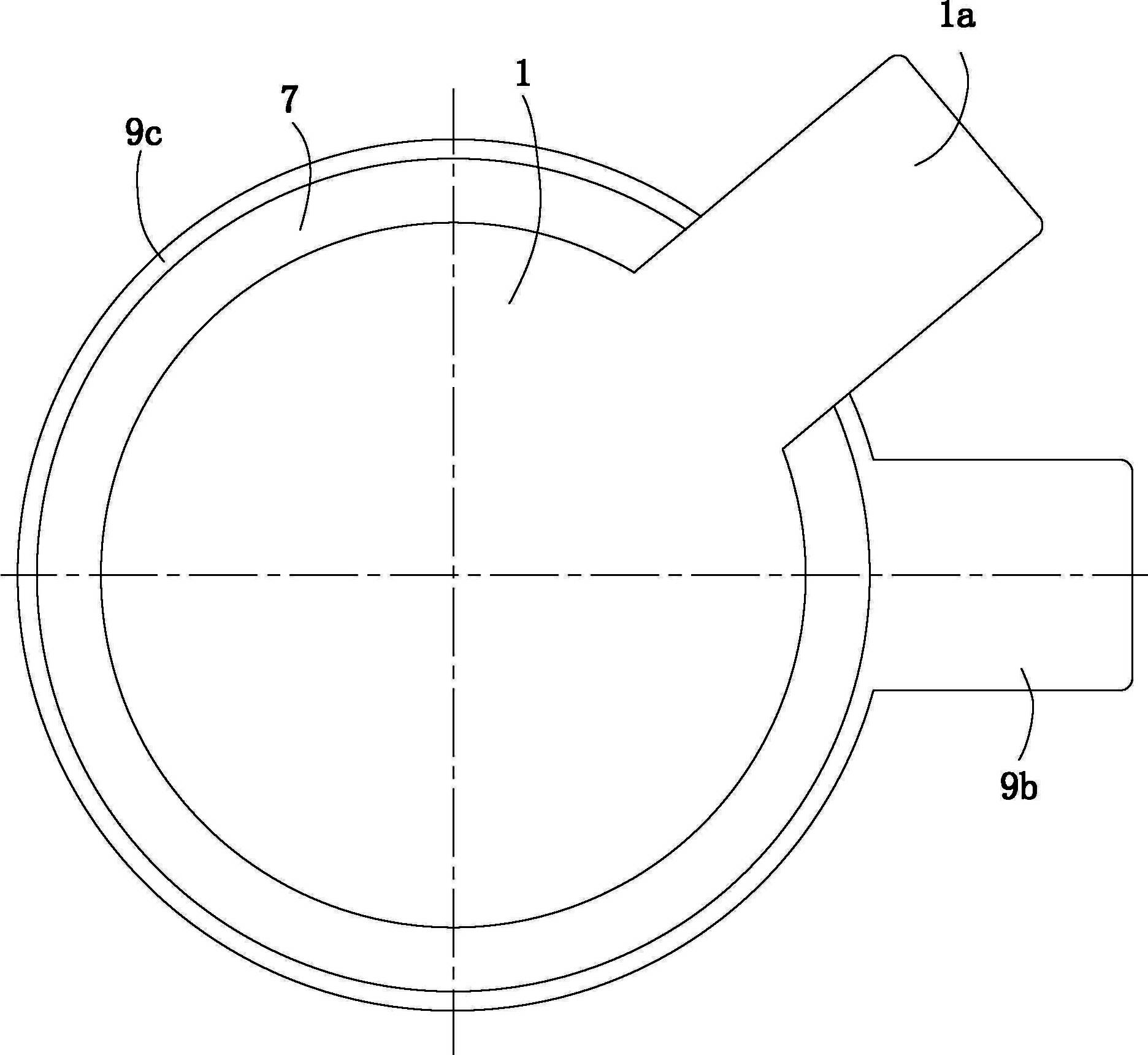

[0025] The relay includes a circular horizontal upper cover 9, a circular horizontal static contact 10, a movable contact 8, a disc-shaped bimetal 5, a circular elastic movable reed 2, a shell with an open upper end and a closed lower end, and an upper cover 9. The inner central area of the top wall is welded with the static contact 10, the upper part of the side wall of the upper cover 9 has a first flange 9c and a first lug 9b extending horizontally outward is arranged through the first flange 9c, and the bimetallic strip 5 The central area has a circular hole ( figure 1 hole key numbers not shown).

[0026] The shell includes a horizontal welding sheet 7, a vertical ceramic metallization isolation cylinder 6, and a horizontal bottom plate 1 welded up and down in sequence, and a circular perforation ( figure 1 The part number of the perforation is not shown in the figure), the upper and lower ends of the isolation cylinder 6 are open...

Embodiment 2

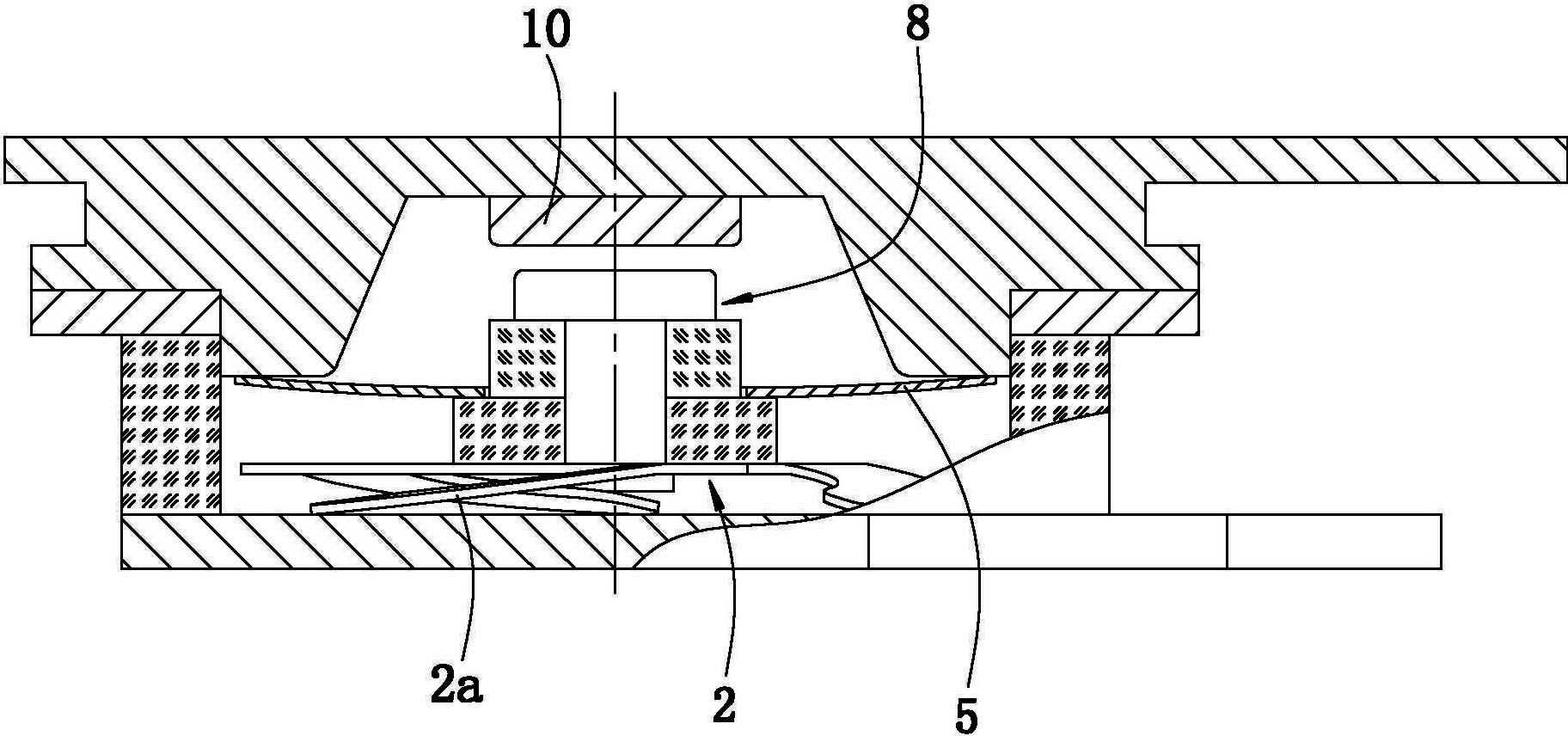

[0036] see image 3 :

[0037] It should be noted that the difference between this embodiment and the first embodiment is only that the bending direction of the bimetal 5 makes the upper end of the movable contact 8 and the static contact 10 in a non-contact state. The rest of the specific structure of this embodiment is the same as that of Embodiment 1, so the rest of the specific structure of this embodiment will not be repeated here.

[0038] Under normal conditions, the upper end of the moving contact 8 and the static contact 10 are in a non-contact state, the relay is in the disconnected state (it is a normally open contact temperature relay), and the moving reed 2 is in a compressed state. When the relay When the sensed temperature meets the operating conditions, the bimetal 5 turns upwards, and under the action of the tension released by the moving reed 2, the moving contact 8 is pushed upwards, and the moving contact 8 and the static contact 10 change from the disconn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com