Method for ultrasonic detection of bonding quality of thin-walled metal and non-metal material

A technology for non-metallic materials and bonding quality, which is used in the analysis of solids and materials using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. It can solve the problems of inaccurate quantitative evaluation and low detection sensitivity. , to achieve the effect of improving quality reliability and use safety, high detection rate, and accurate quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

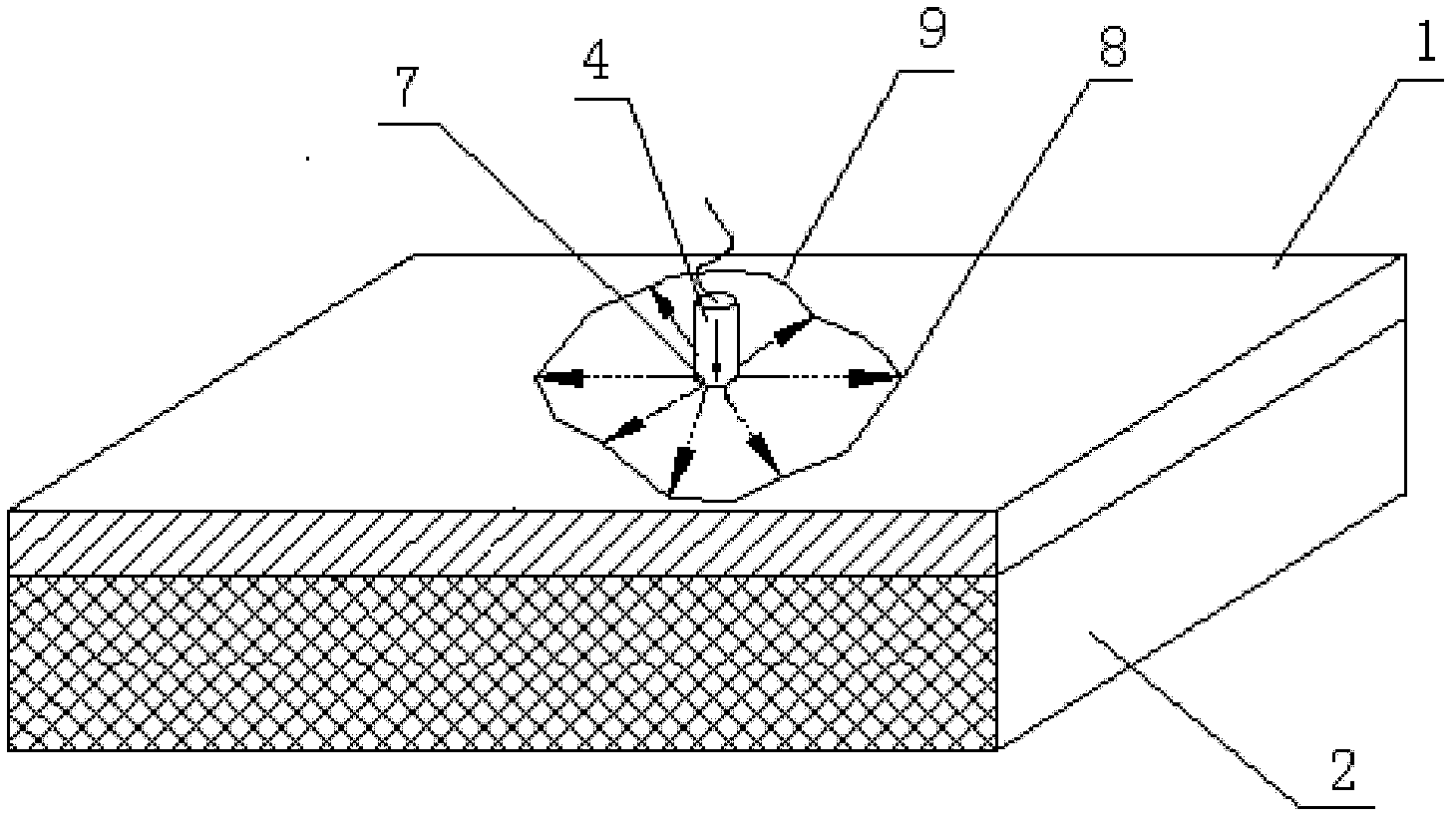

Image

Examples

Embodiment 1

[0043] Example 1: When testing the bonding quality of a ZTC4 cast titanium alloy cylindrical shell with an outer diameter of φ300mm and a wall thickness of 3.0mm and a high-silica molded material bonding product, the acceptance technical requirements stipulate that no single area is greater than 2000mm 2 If the debonding defect exists, according to the metal structure of the inspected product, the sound attenuation characteristics of the material and the inspection accuracy requirements, the inspection frequency of the probe can be selected as 2.25MHz.

Embodiment 2

[0044] Example 2: When testing the bonding quality of a ZL104 cast aluminum alloy plate ring with an outer diameter of φ600mm, an inner diameter of 200mm, and a thickness of 5.0mm, and a rubber material bonding product, the technical requirements for acceptance shall not have a single area greater than 800mm 2 If the debonding defect exists, according to the metal structure of the inspected product, the sound attenuation characteristics of the material and the detection accuracy requirements, the detection frequency of the probe can be selected as 3MHz.

Embodiment 3

[0045] Example 3: When testing the bonding quality of a steel forging cone shell with an outer diameter of φ450mm at the large end, an outer diameter at the small end of 300mm, and a wall thickness of 4.0mm, and a carbon fiber braided material bonding product, the acceptance technical requirements stipulate that there must be no single area Greater than 400mm 2 If the debonding defect exists, according to the metal structure of the inspected product, the sound attenuation characteristics of the material and the detection accuracy requirements, the detection frequency of the probe can be selected as 5MHz.

[0046] (2) Chip size of the probe: The chip size of the probe is determined according to the external dimensions and structure of the detected thin-walled metal and non-metallic material products and the detection accuracy. While coupling, it should also meet the requirements of detection accuracy and have a good signal-to-noise ratio. When the thin-walled metal of the detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com