Nitrogen-oxygen sensor

A nitrogen and oxygen sensor, a sensitive technology, applied in the field of sensors, can solve the problems of limited application range, easy failure, poor selectivity, etc., and achieve the effect of simple manufacturing process, wide measurement range and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

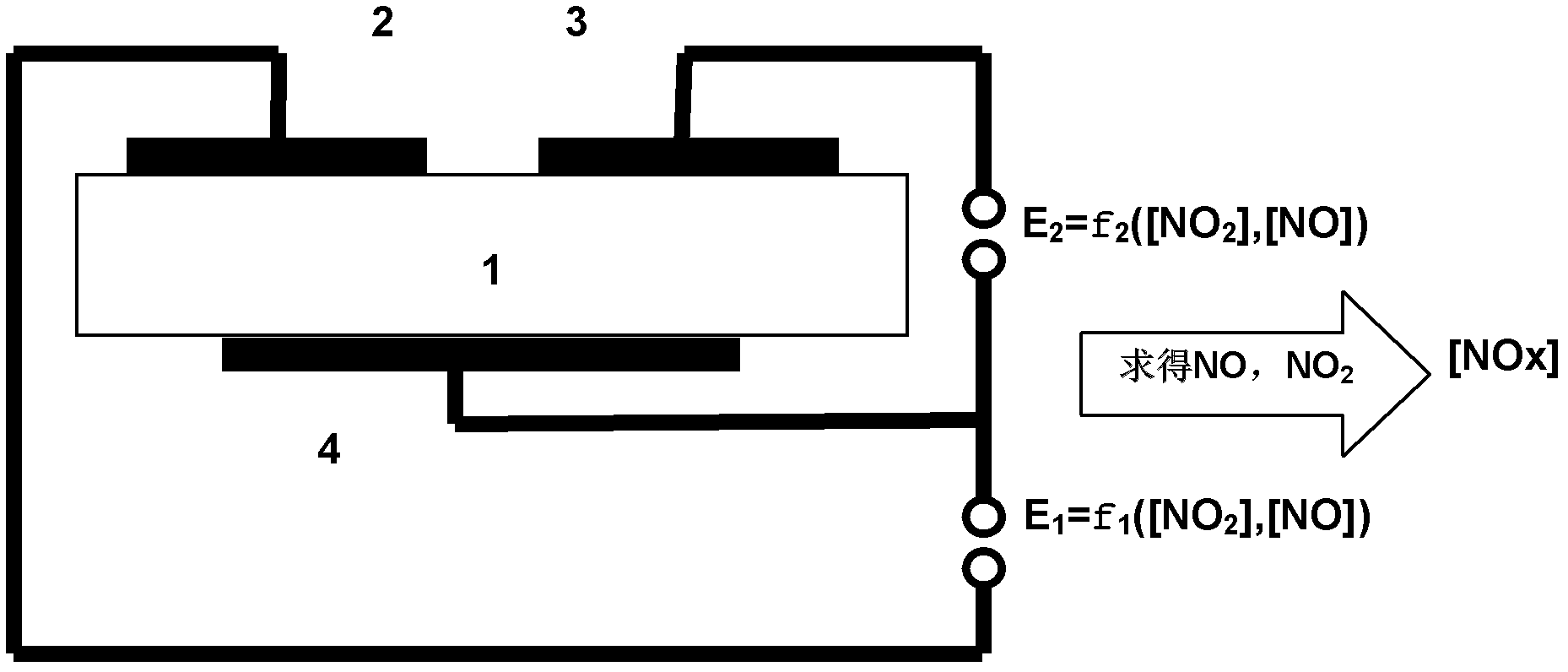

Method used

Image

Examples

example 1-3

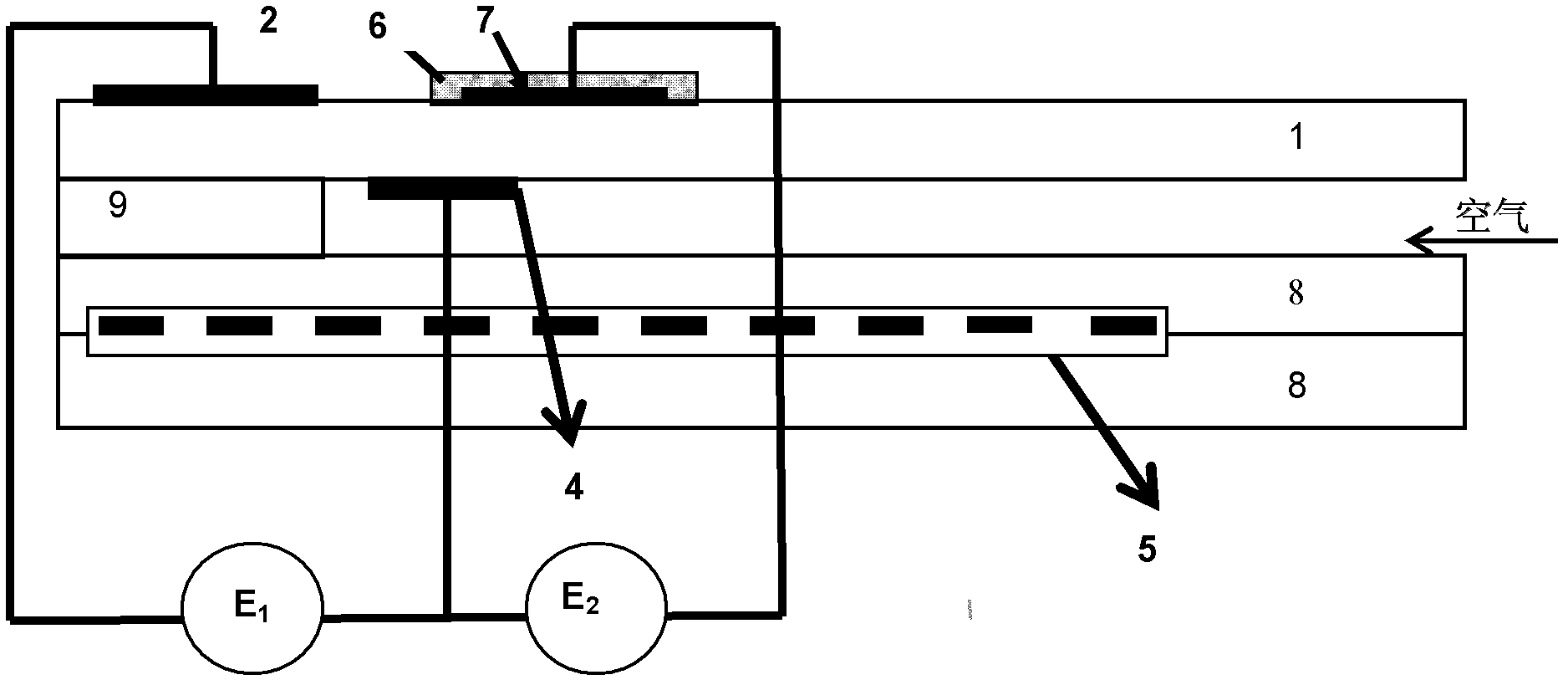

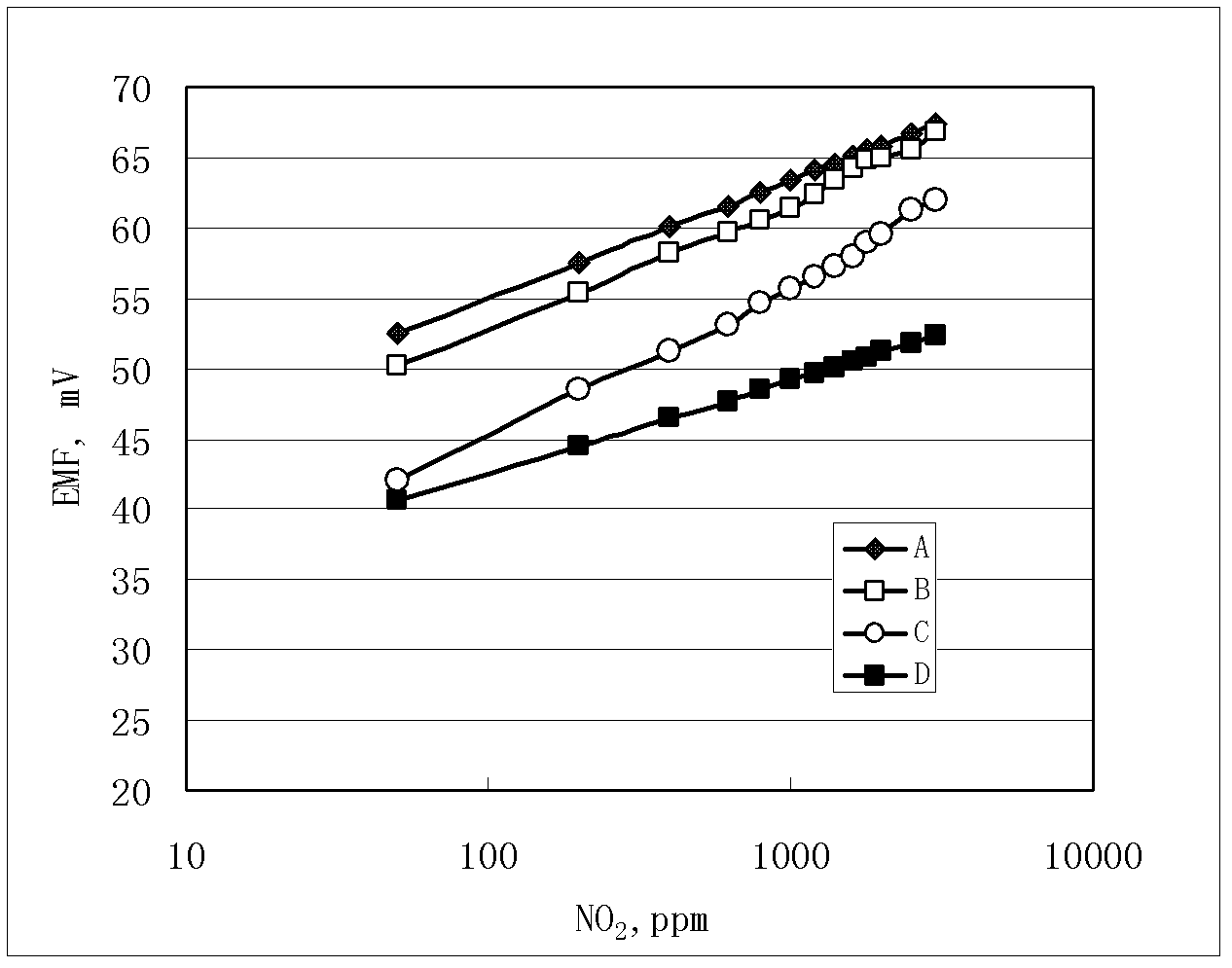

[0038] Examples 1-3 adopt figure 2 As shown in the structure, the material of base 1 is composed of 5moleY 2 O 3 The electrode 3 is made of CuO layer 7 and the cover layer 6 (the electric potential value E1 is curve D), the cover layer 6 is made of spinel material containing 5vol% Mn, and the electrode 4 is made of Pt. The resistance is made of Pt. The electrode 2 of Example 1 is made of NiO+15vol% YSZ (the potential value E2 is curve A), the electrode 2 of Example 2 is made of NiO+5vol% YSZ (the potential value E2 is curve B), and the electrode 2 of Example 3 is made of Made of NiO+30vol% YSZ (the potential value E2 is curve C).

[0039] image 3 For adoption figure 2 The sensor obtained by the device shown in Example 1, the NO obtained under the condition of different composition sensitive electrodes 2 The relationship between gas concentration and electrode potential.

[0040] Figure 4 For adoption figure 2 In the device shown, in Example 1, the NiO (+15wt% YSZ) electrode i...

example 4-6

[0044] The materials and components of each part in Examples 4-6 are shown in the following table

[0045] Matrix 1

[0046] The sensors obtained in Examples 4-6 can also achieve the technical effects of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com