Testing system for critical pressure during thermal explosion of explosives

A critical pressure and test system technology, applied in the direction of material explosion, can solve the problems of large deviation of powder column or slurry, small sample size, and no consideration of scale effect, etc., and achieve the effect of improving the uniformity and stability of the temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

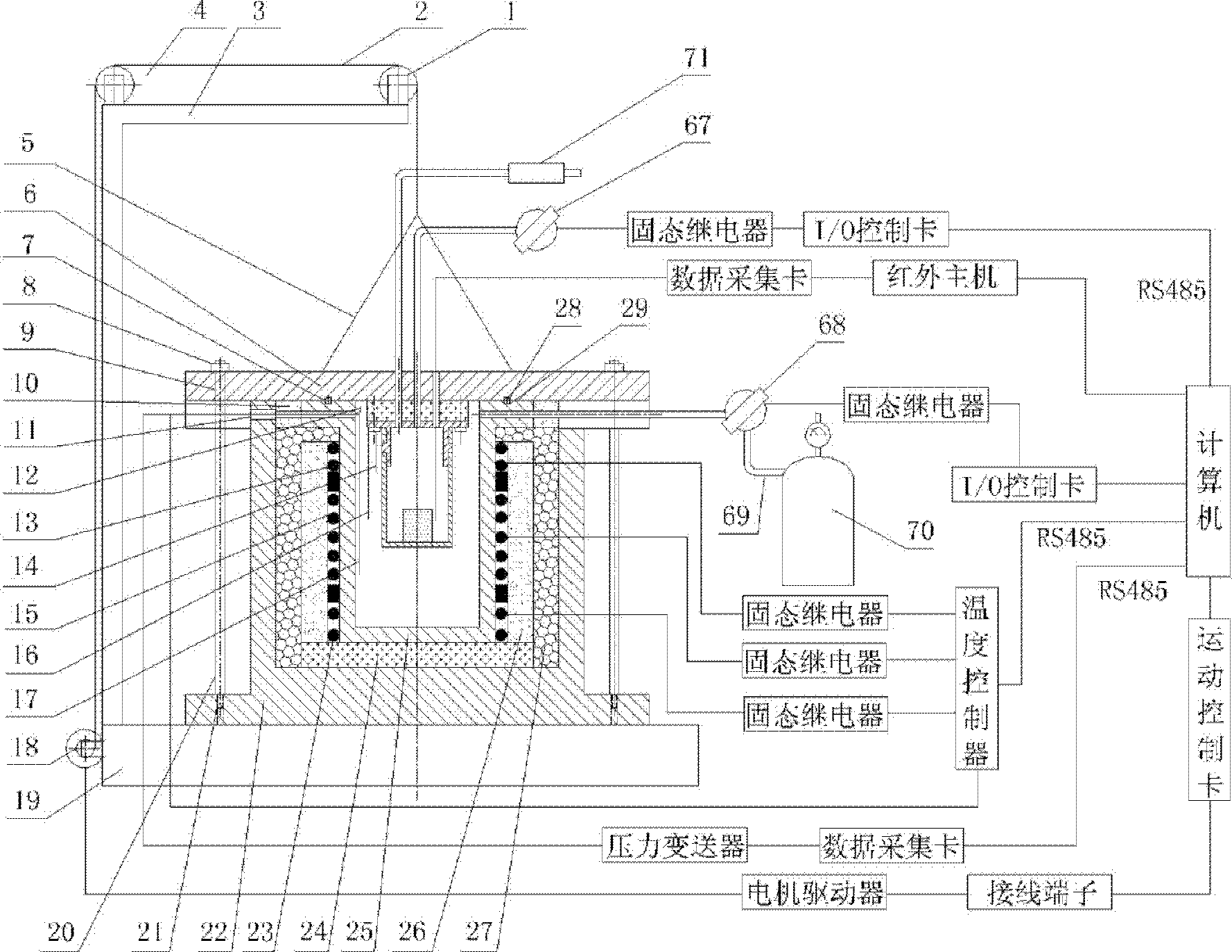

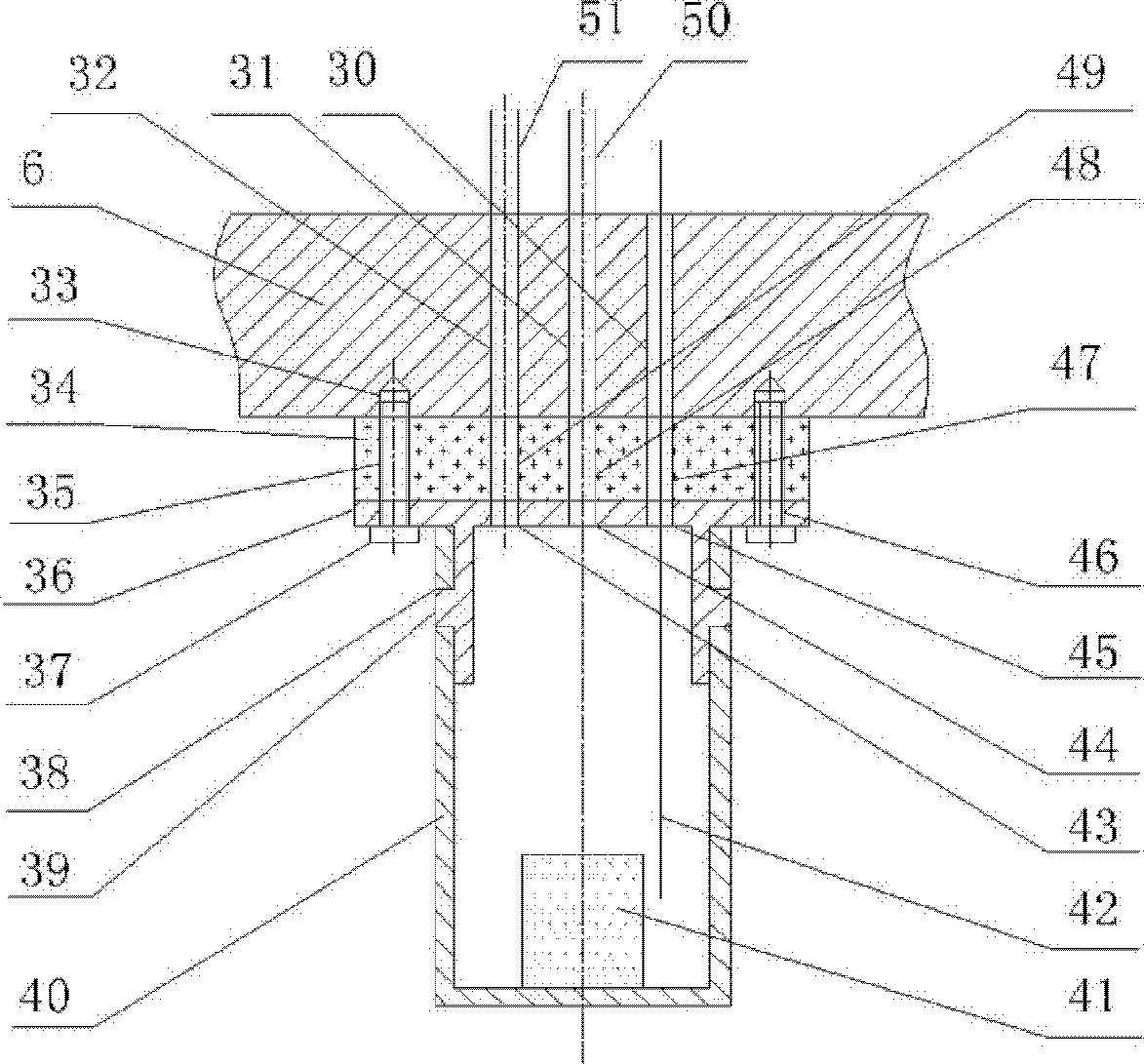

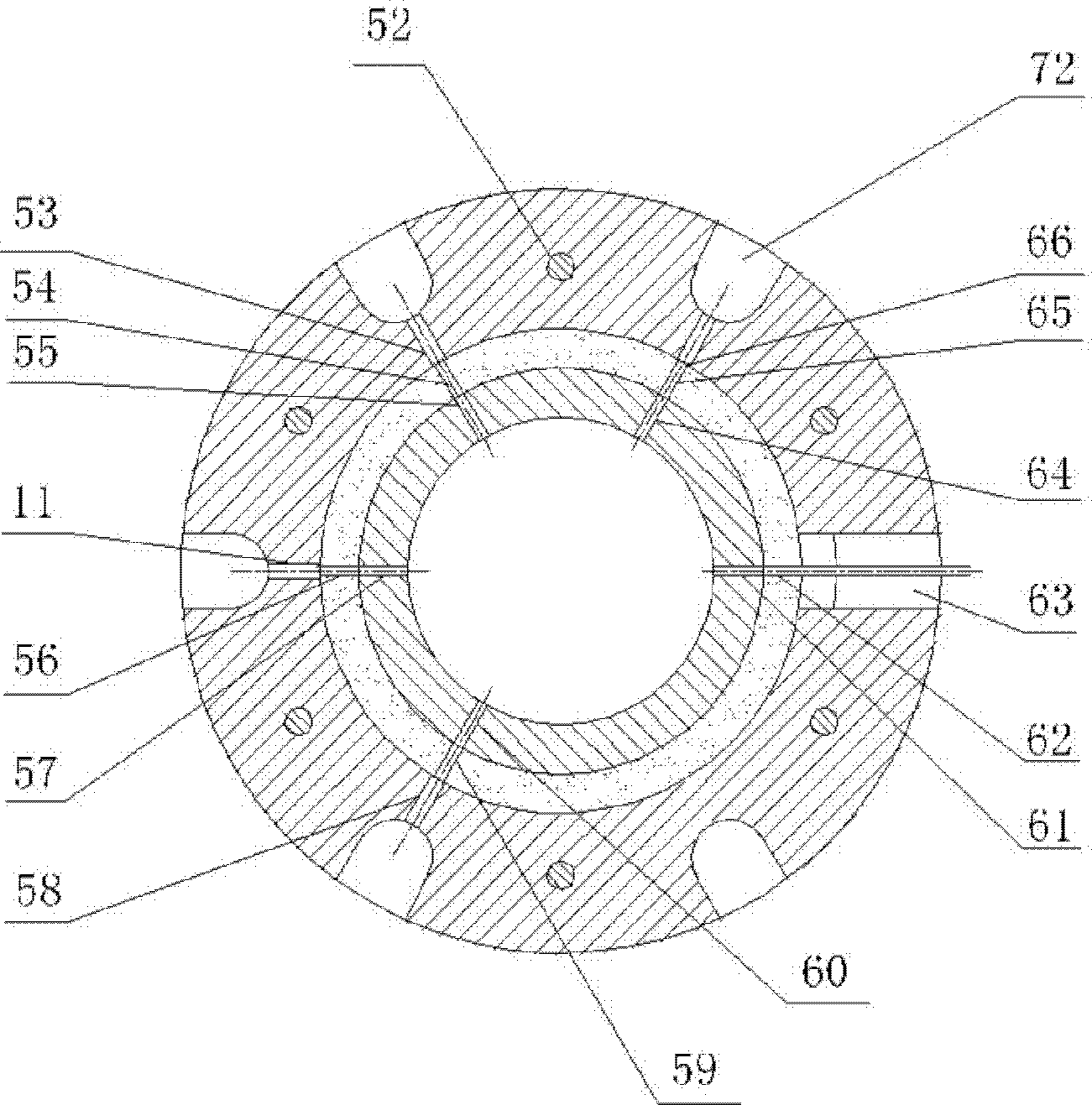

[0021] see Figure 1 ~ Figure 4 , this embodiment provides a thermal explosion critical pressure test system for explosives, including a heating unit, a sample carrier unit, a pressure control unit, a critical state detection unit and a computer.

[0022] The heating unit comprises a single chamber with a heat conducting layer 25, three groups of heating layers (upper heating layer 13, middle heating layer 15, lower heating layer 23), furnace body insulation layer 26, ceramic heat insulating layer 27 and housing 22 The heating furnace body has independent heating wires in each heating layer; the upper layer temperature sensor 14 connected to the computer, the middle layer temperature sensor 16, and the lower layer temperature sensor 17 are respectively equipped with the bottom, middle, and upper parts of the furnace cavity. relays and temperature controllers. The temperature and heating rate of the heating furnace body are controlled by computer. in:

[0023] The heat condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com