High-reliability method and device for gas concentration measurement

A gas concentration measurement and reliability technology, which is applied in the field of medical breathing gas concentration measurement, can solve problems such as increasing costs, achieve the effects of improving working life, improving long-term reliability, and reducing system power consumption and hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

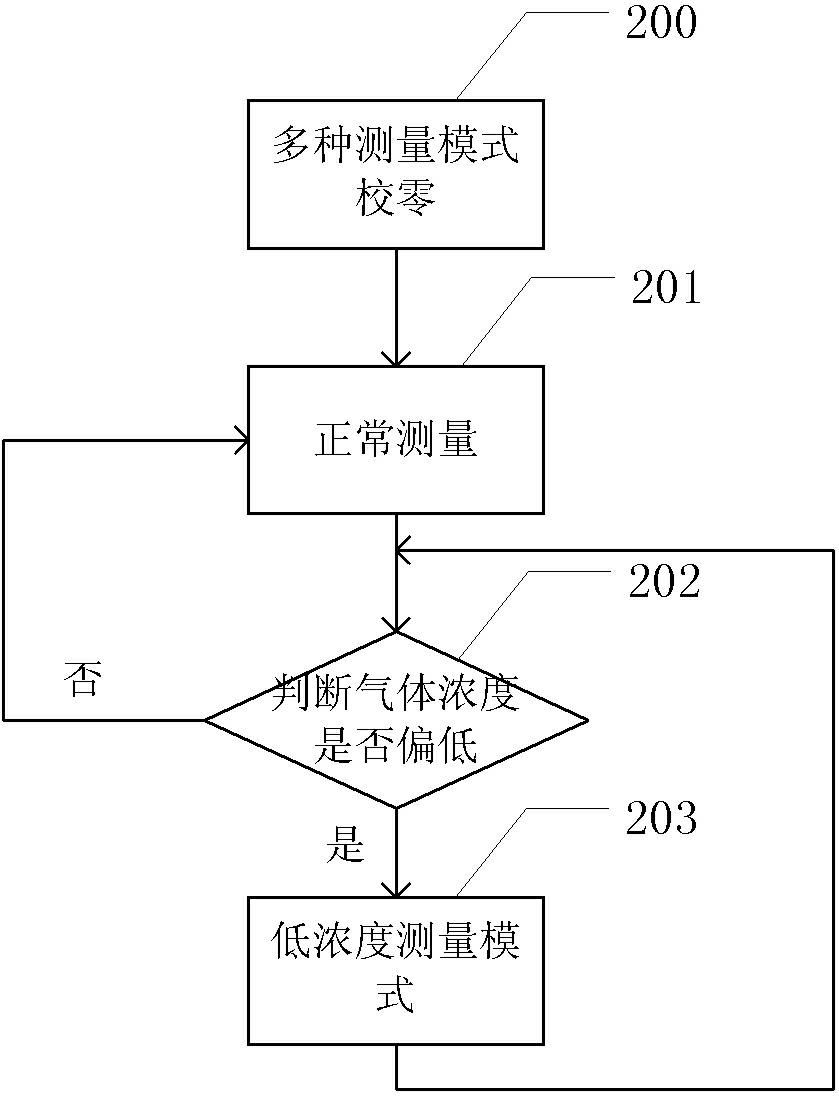

[0050] Such as figure 1 Shown, a kind of highly reliable gas concentration measurement method of the present invention, it mainly comprises:

[0051] Step Ⅰ, preset the scene parameter range threshold and the infrared light source driving power value of the corresponding scene; then the system is zeroed, that is, when the measured gas is not introduced into the measuring device, the infrared light signal emitted by the infrared light source that is not absorbed by the gas is collected, Measure and save the signal strength as the calculation zero point and save;

[0052] Step II, preset mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com