Water baffle mounted in inner container of water heater

A water heater liner and water baffle technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of not being able to extrude hot water from the upper layer, impacting the water flow on the inner wall of the liner, and destroying the stratification of cold and hot water. Avoid water rebound and disturbance stratification, water inflow is evenly distributed, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

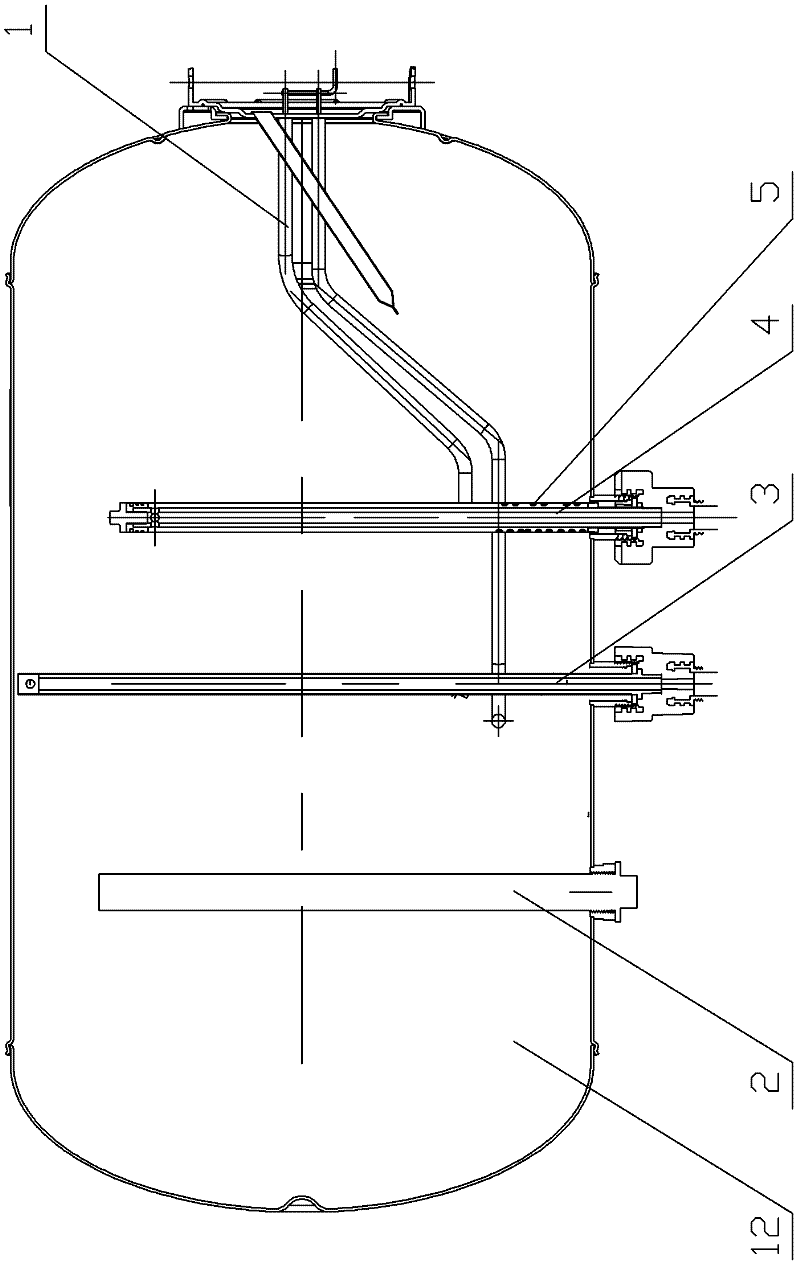

[0042] Such as figure 1 As shown, the structure diagram of the water heater liner in the prior art is given, including the liner 12, the electric heating tube 1, the water inlet pipe 4, and the water outlet pipe 3, and the magnesium rod 2 is installed, and the bottom of the water inlet pipe 4 is provided with a water outlet Hole 5 is used as the outlet of the water inlet pipe. When the flow velocity of the water inlet is too large, it will impact the inner wall of the inner tank, and the rebounding water flow will disturb the stratification of cold and hot water.

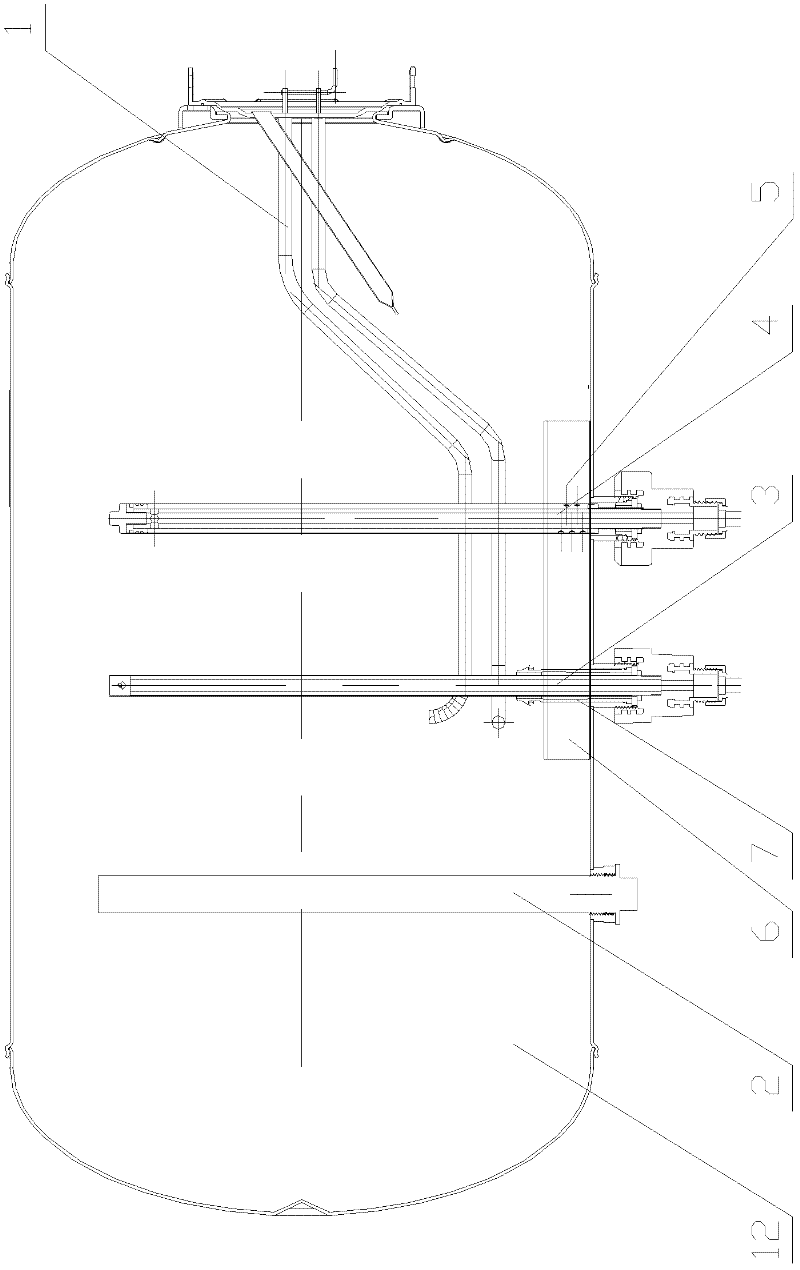

[0043] Such as Figure 2-6 As shown, the first embodiment of the water baffle installed in the inner tank of the water heater of the present invention is provided. As shown in the figure, the water baffle 6 is provided with convex edges 11 on the opposite sides, and is connected with the inner tank 12. The inner wall forms a cavity, and the corresponding openings at the other two ends serve as diversion passages fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com