Central air-conditioning system and control method thereof

A central air-conditioning system and thermostat technology, which is applied in heating systems, central heating components, heating and ventilation control systems, etc., can solve problems such as unrealistic energy deployment, terminal output oscillation, and increased refrigerant flow, etc., to achieve reduction The amount of circulating water in the system, the effect of solving the problem of large pressure difference at the proximal end and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

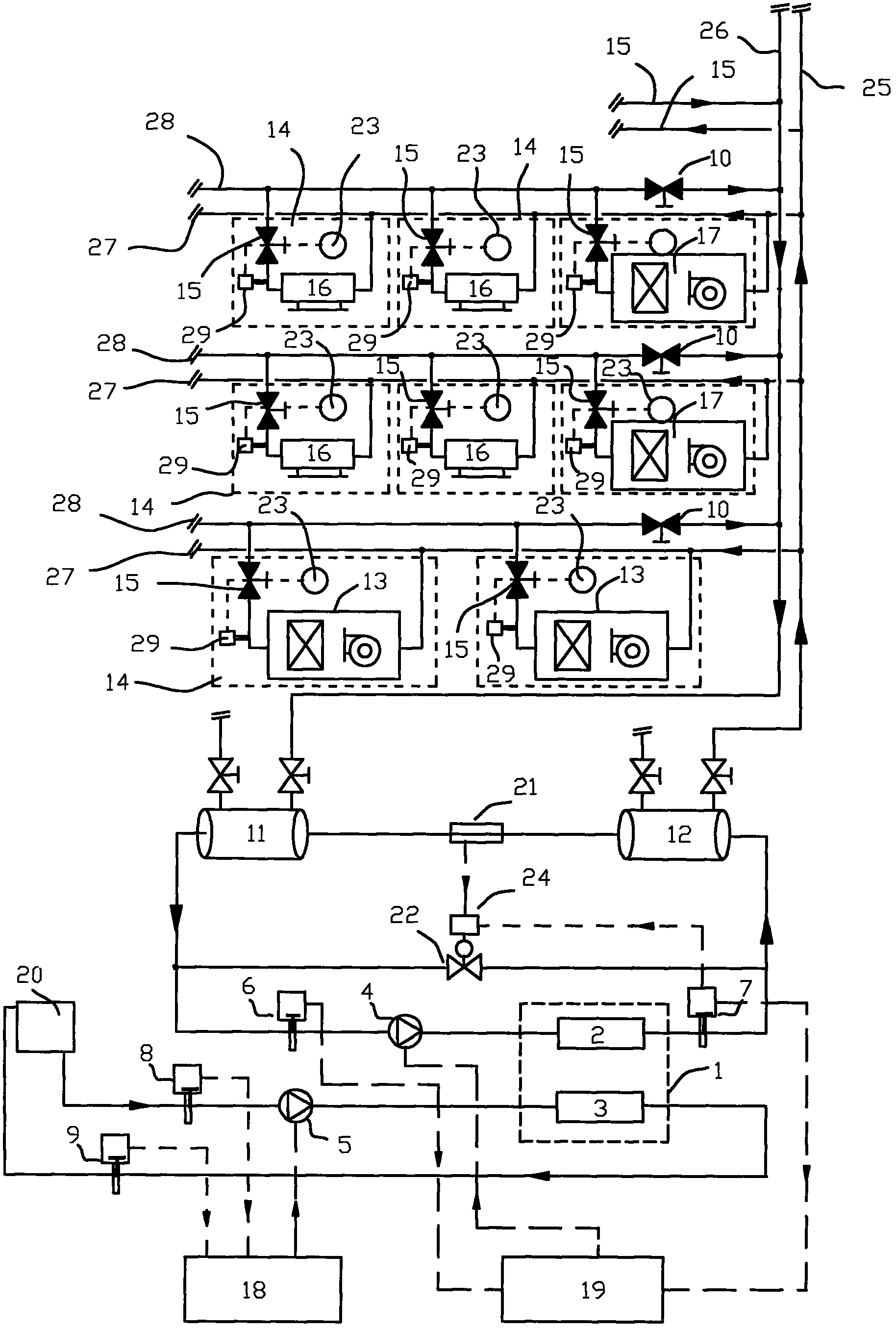

[0035] refer to figure 1 , a central air-conditioning system, comprising a refrigerating unit 1, a cooling water circuit, a cooling water pump 5 arranged on the cooling water circuit, a cooling water pump frequency converter 18, a circulating water circuit, a circulating water pump 4 arranged on the circulating water circuit, a circulating water pump Frequency converter 19, several circulating water branches arranged in parallel on the circulating water circuit, and thermostats 23, terminal fan coils 16, fresh air unit 17 and air handling unit 13 arranged in each room 14, wherein the circulating water circuit includes The main water inlet pipe 25 and the water return main pipe 26, the circulating water branch includes the water inlet branch pipe 27 and the water return branch pipe 28, and the terminal fan coil unit 16, the fresh air unit 17 and the air handling unit 13 are respectively arranged in parallel on the circulating water branch road. The return water branch pipes 28 ...

Embodiment 2

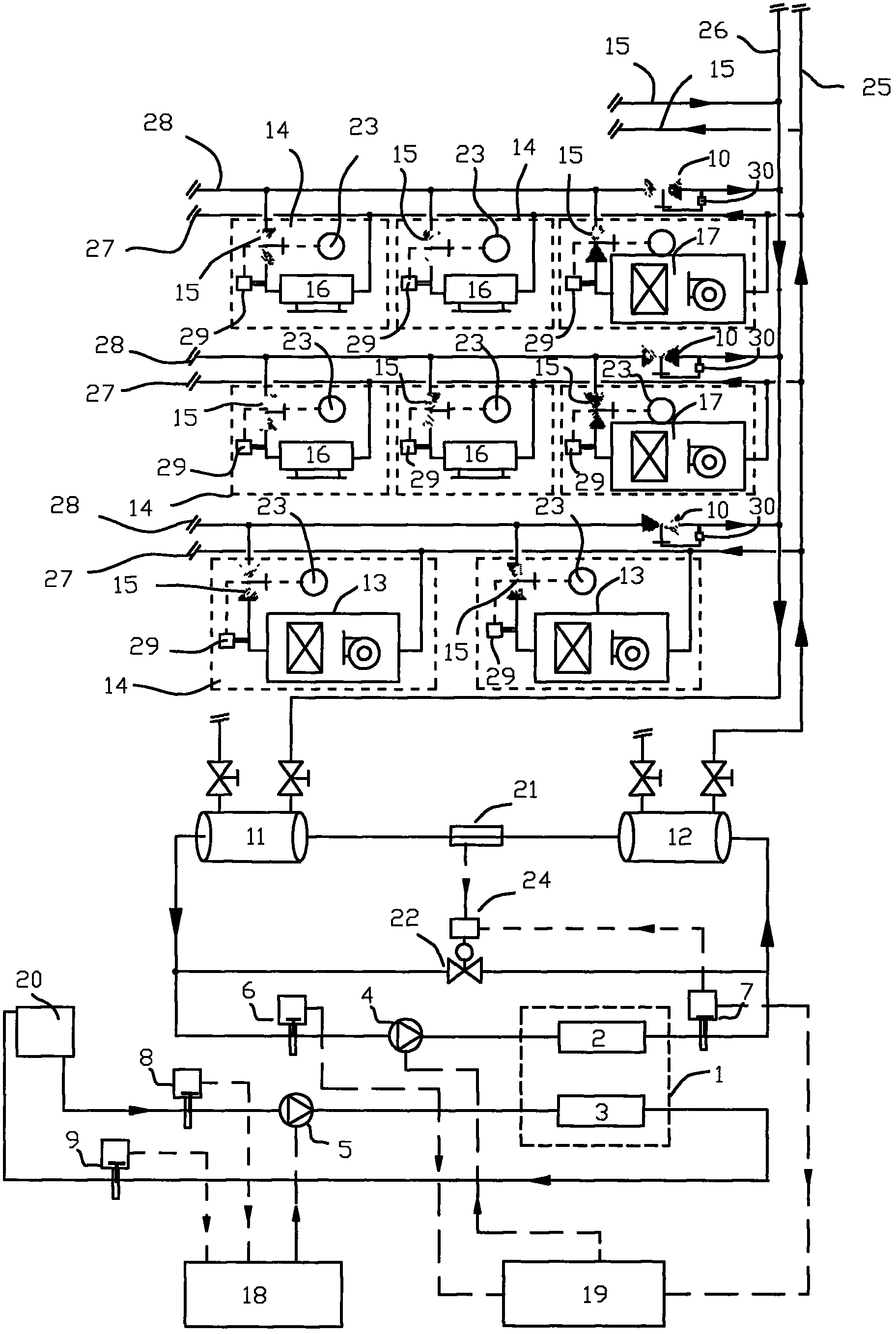

[0050] refer to image 3 , a central air-conditioning system, comprising a refrigerating unit 1, a cooling water circuit, a cooling water pump 5 arranged on the cooling water circuit, a cooling water pump frequency converter 18, a circulating water circuit, a circulating water pump 4 arranged on the circulating water circuit, a circulating water pump Frequency converter 19, several circulating water branches arranged in parallel on the circulating water circuit, and thermostats 23, terminal fan coils 16, fresh air unit 17 and air handling unit 13 arranged in each room 14, wherein the circulating water circuit includes The main water inlet pipe 25 and the water return main pipe 26, the circulating water branch includes the water inlet branch pipe 27 and the water return branch pipe 28, and the terminal fan coil unit 16, the fresh air unit 17 and the air handling unit 13 are respectively arranged in parallel on the circulating water branch road. The return water branch pipes 28 ...

Embodiment 3

[0065] refer to Figure 5 , is another central air-conditioning system, comprising a refrigeration unit 1, a cooling water circuit, a cooling water pump 5 arranged on the cooling water circuit, a cooling water pump frequency converter 18, a circulating water circuit, a circulating water pump 4 arranged on the circulating water circuit, Circulating water pump frequency converter 19, several circulating water branches arranged in parallel on the circulating water circuit, thermostats 23 arranged in each room 14, terminal fan coil unit 16, fresh air unit 17 and air handling unit 13, in which the circulating water The loop includes a water inlet main pipe 25 and a water return main pipe 26. The circulating water branch includes an inlet water branch pipe 27 and a water return branch pipe 28. The terminal fan coil unit 16, fresh air unit 17 and air handling unit 13 are respectively arranged in parallel on the circulating water branch road. Each of the return water branch pipes 28 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com