Top drive control system of hydraulic drive

A technology of control system and top drive, which is applied to the automatic control system of drilling, drilling equipment and methods, construction, etc., and can solve the problems of blank hydraulic top drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

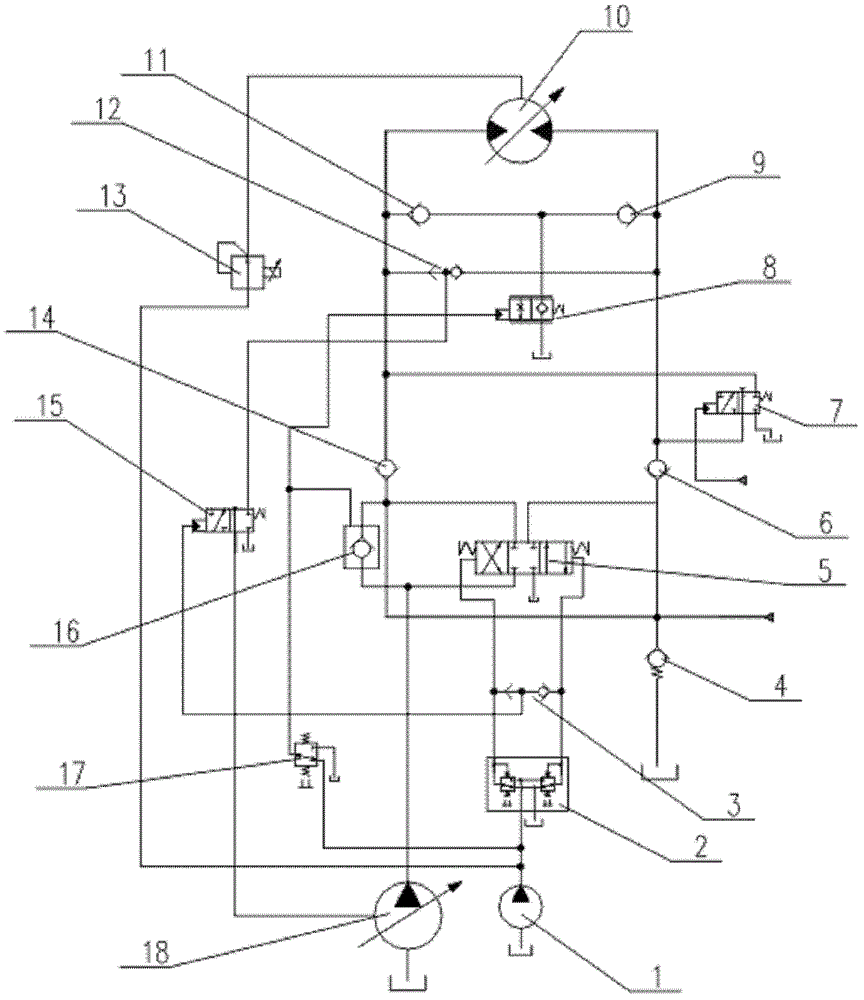

[0008] As shown in the drawings, a hydraulically driven top drive control system includes a control pump 1, a control handle 2, a motor 10 and a variable pump 18; the outlet of the variable pump 18 is connected to the inlet of the hydraulic control proportional reversing valve 5, and the hydraulic The two outlets of the proportional control valve 5 are respectively connected to the two working oil ports of the motor 10 through the check valve II6 and the check valve V14; the outlet of the control pump 1 is connected to the inlet of the control handle 2, and the two ports of the control handle 2 The two outlets are connected to the two control ports of the hydraulic control proportional reversing valve 5, and are also connected to the two inlets of the shuttle valve I3; the outlet of the shuttle valve I3 is connected to the control port of the hydraulic control reversing valve II15, and the hydraulic control reversing valve The inlet of the direction valve II15 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com