Building structure and construction method

A kind of building structure and combined technology, applied in the direction of building structure, construction, etc., can solve the problems of discounted bearing capacity, poor supporting bearing capacity, poor overall rigidity, etc., and achieve the effect of low cost, easy installation and fixing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

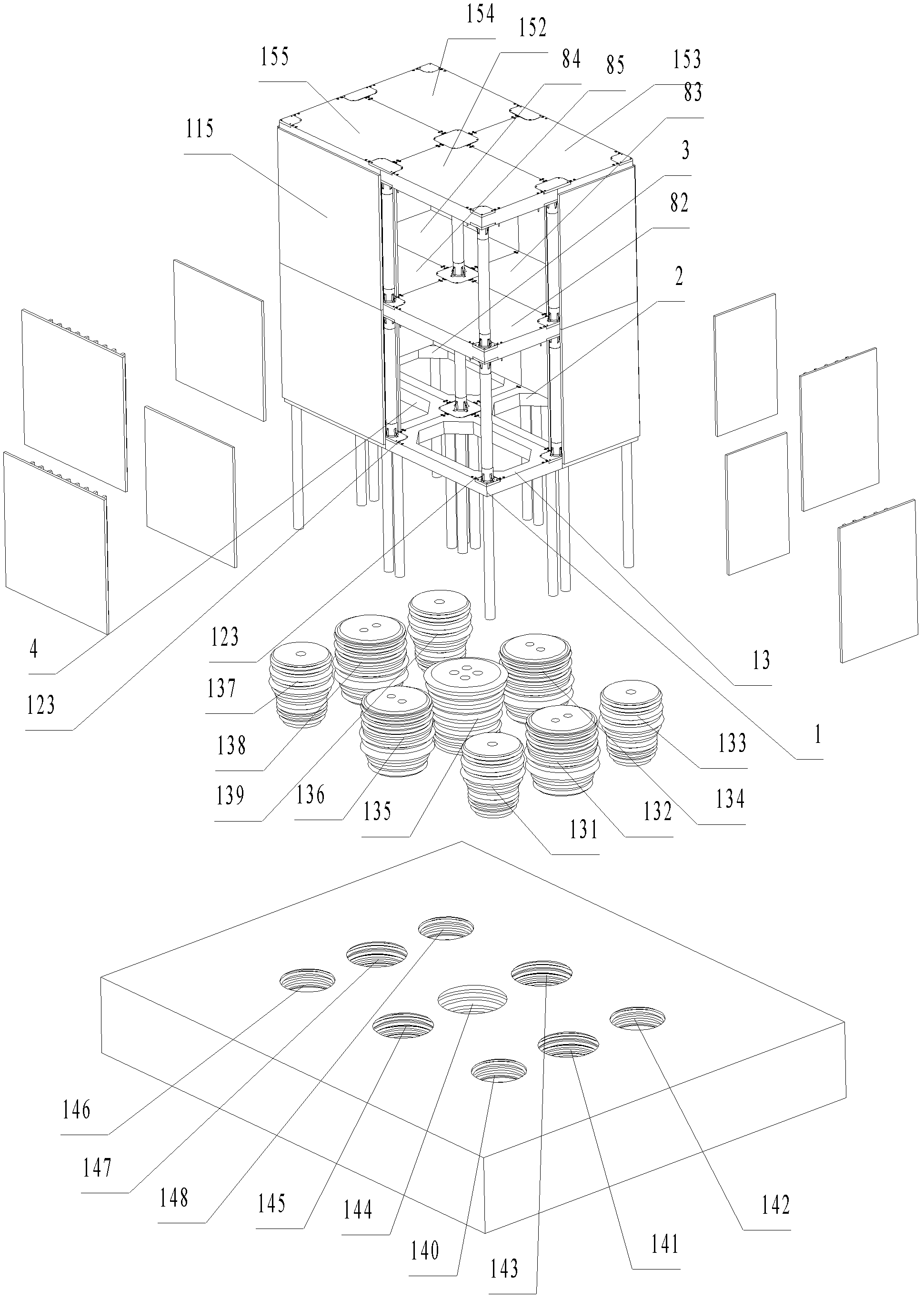

[0198] Such as figure 1 As shown, a house includes a square prefabricated frame 1 , a prefabricated frame 2 , a prefabricated frame 3 , and a prefabricated frame 4 that are spliced in pairs on the ground floor and have the same structure.

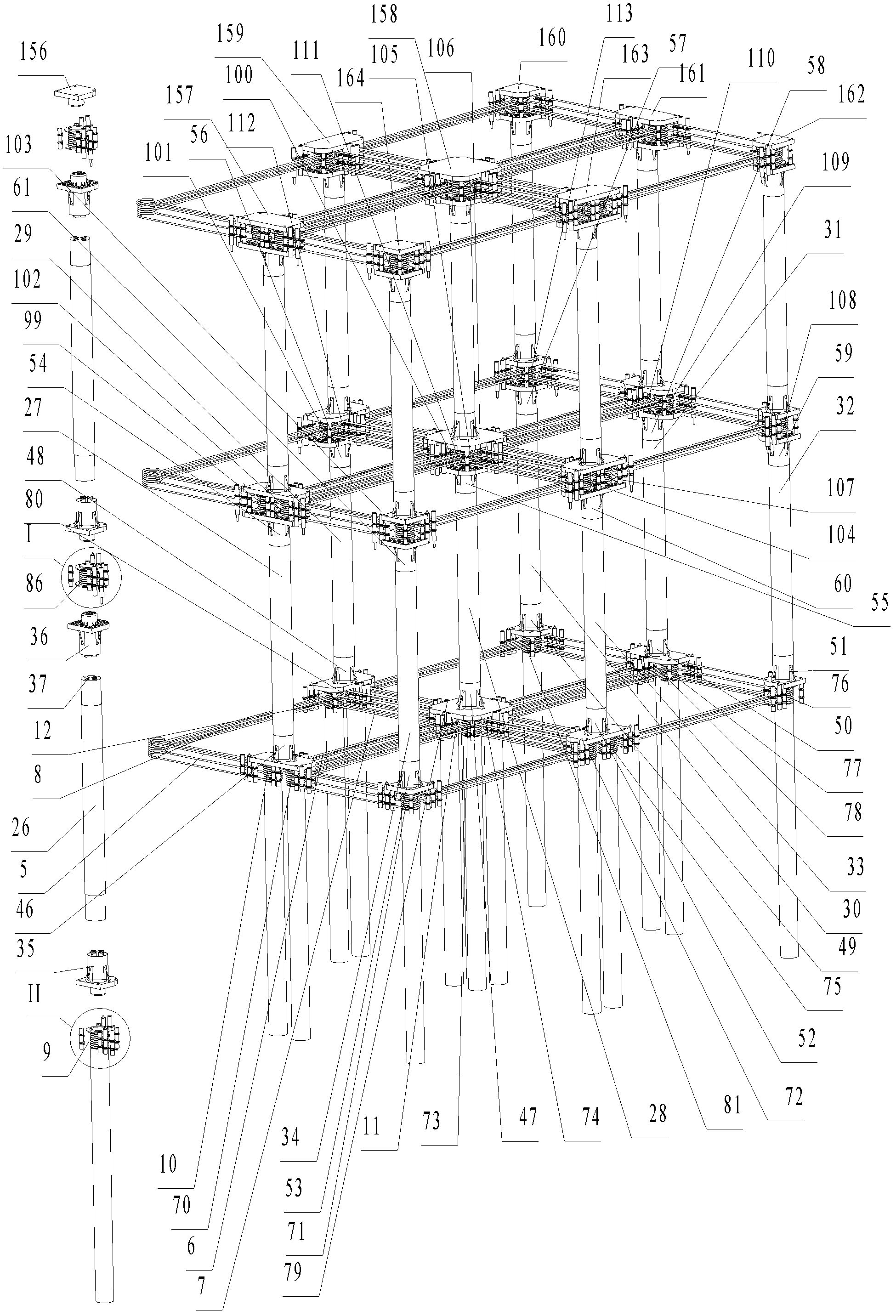

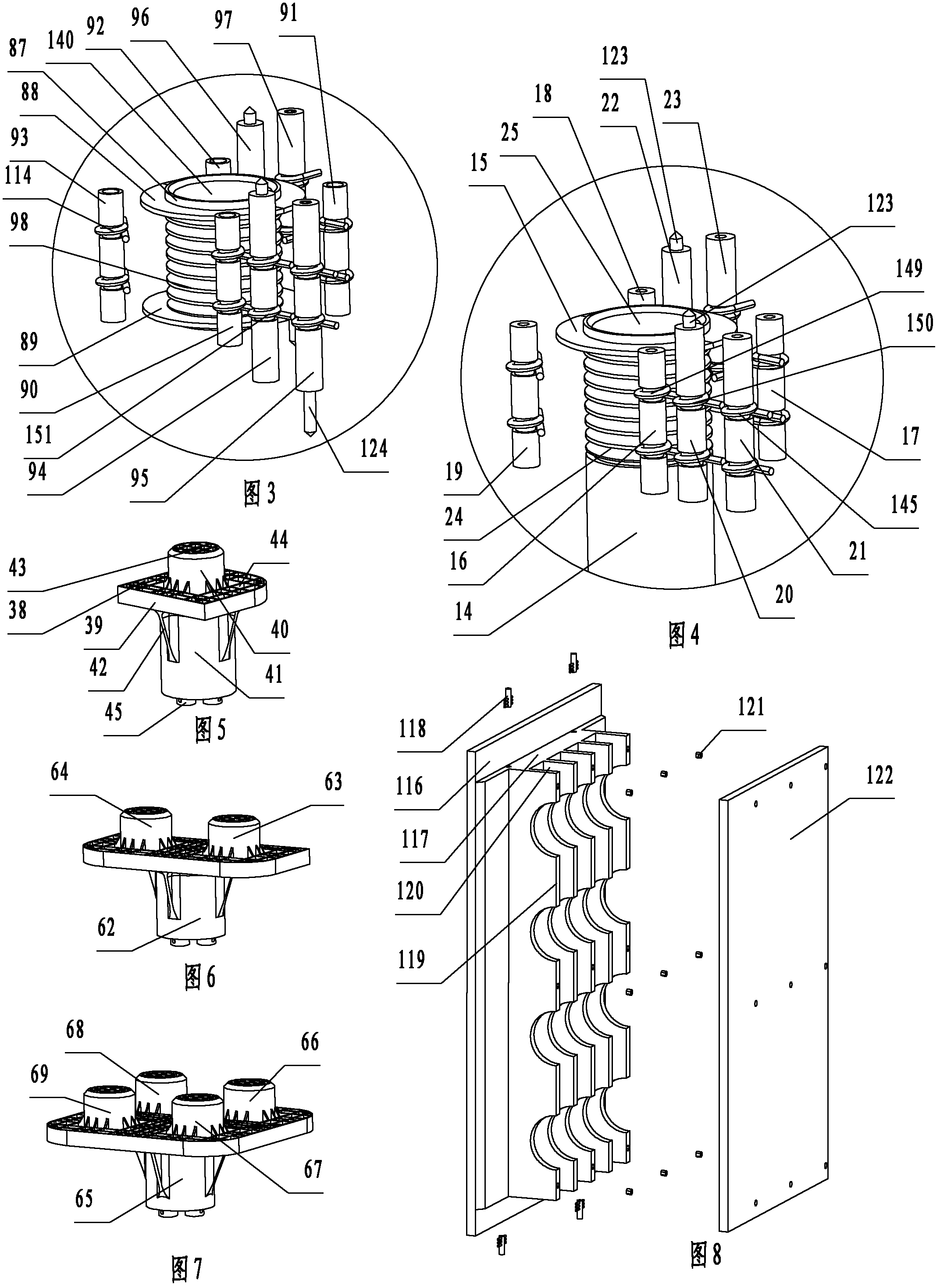

[0199] Such as figure 2 As shown, the prefabricated frame 1 includes a reinforced beam 5, a reinforced beam 6, a reinforced beam 7, and a reinforced beam 8 embedded in the prefabricated frame 1, corresponding to the four sides of the prefabricated frame 1, and each side is composed of four steel bars. , the pre-embedded connector 10 connecting the connection nodes at the ends of the reinforced beam 5 and the reinforced beam 6, the embedded connector 11 connecting the connected nodes at the ends of the reinforced beam 6 and the reinforced beam 7, connecting the reinforced beam 7 and the 8 ends of the reinforced beam The pre-embedded connector 12 of the connection node of the part, the pre-embedded connector 9 of the connection node conne...

Embodiment 2

[0225] Such as Figure 9 to Figure 10 As shown, the difference from Example 1 is that each prefabricated frame on the bottom layer, each prefabricated board on the middle layer, and each prefabricated board on the top layer are bent and wound in the slots 171 of the round tubes of the embedded connectors. Resist steel bar 172. The lower end of the round tube of the embedded connector of each prefabricated panel on the top floor is the first positioning column 173 . The lower end of the round tube of the embedded connector of each prefabricated panel in the middle layer is the first positioning column 174 and the upper end is the first positioning column 175 . The upper end of the circular tube of the pre-embedded connector of each prefabricated frame on the bottom floor is the first positioning column 176, and the lower end of the circular tube of the pre-embedded connector is the short pipe pile 177 embedded in the ground. All the column connectors cooperate with the first ...

Embodiment 3

[0227] Such as Figure 11 As shown, the difference from Example 1 is that the upper end of the round tube of the embedded connector of each prefabricated frame on the ground floor, the upper end and lower end of the round tube of the embedded connector of each prefabricated panel in the middle layer 1. The upper end of the round tube of the embedded connector of each prefabricated panel on the top floor is a stepped part with a small end and a large middle part. An annular baffle 191 is set on the small end 190 of the stepped part. The baffle 191 One end surface is attached to the end surface of the big end 192 of the stepped part, and the baffle plate 191 is welded on the round pipe. All the round pipes of the pre-embedded connectors are not provided with a draw-in groove and two semi-circular baffles welded and fixed in the draw-in groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com