Inspection well

A technology for inspection wells and shafts, applied in the field of inspection wells, can solve the problems of low compressive strength of inspection wells, easy leakage and construction difficulty, etc., and achieve the effects of avoiding sewage leakage, light weight and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

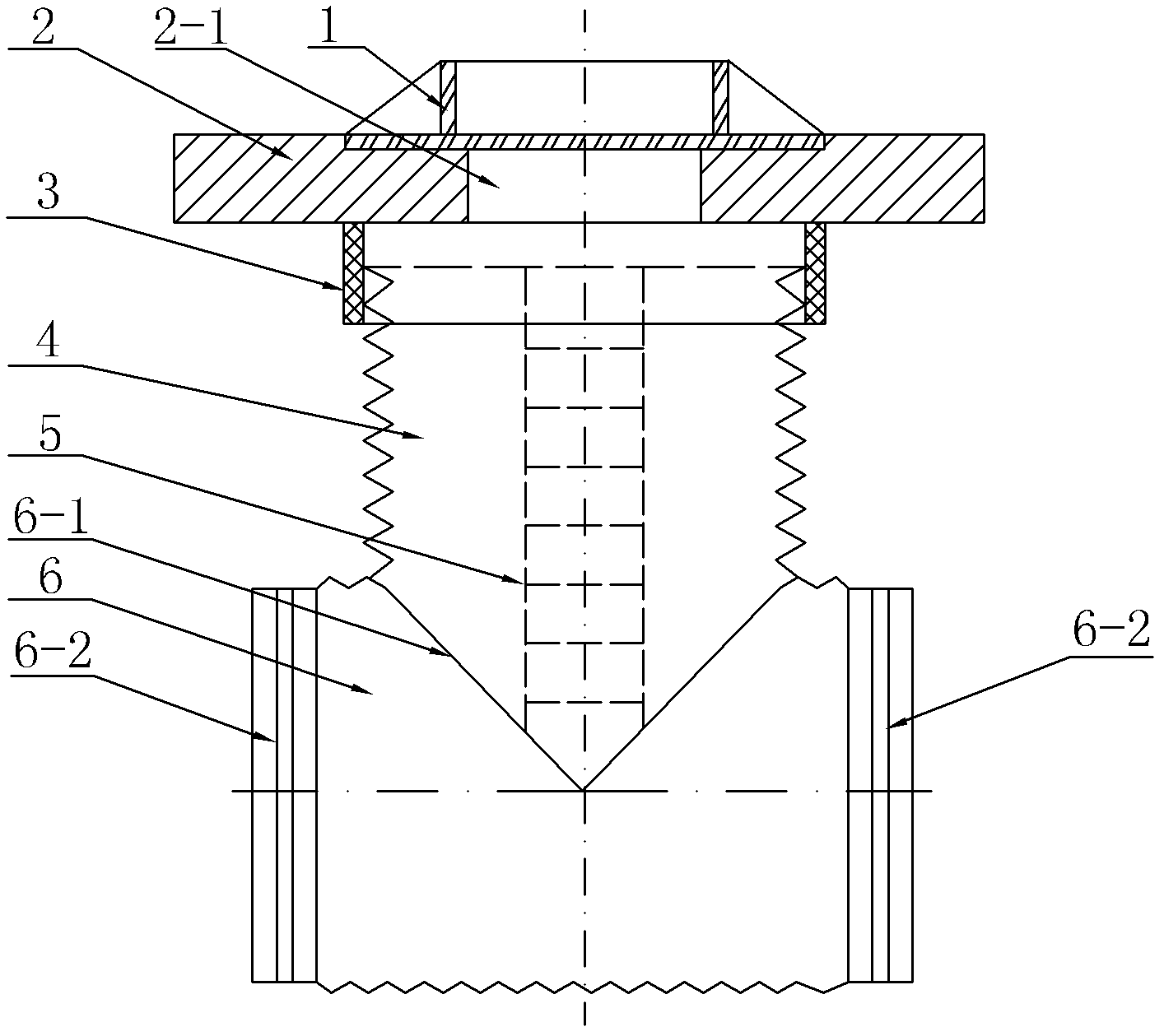

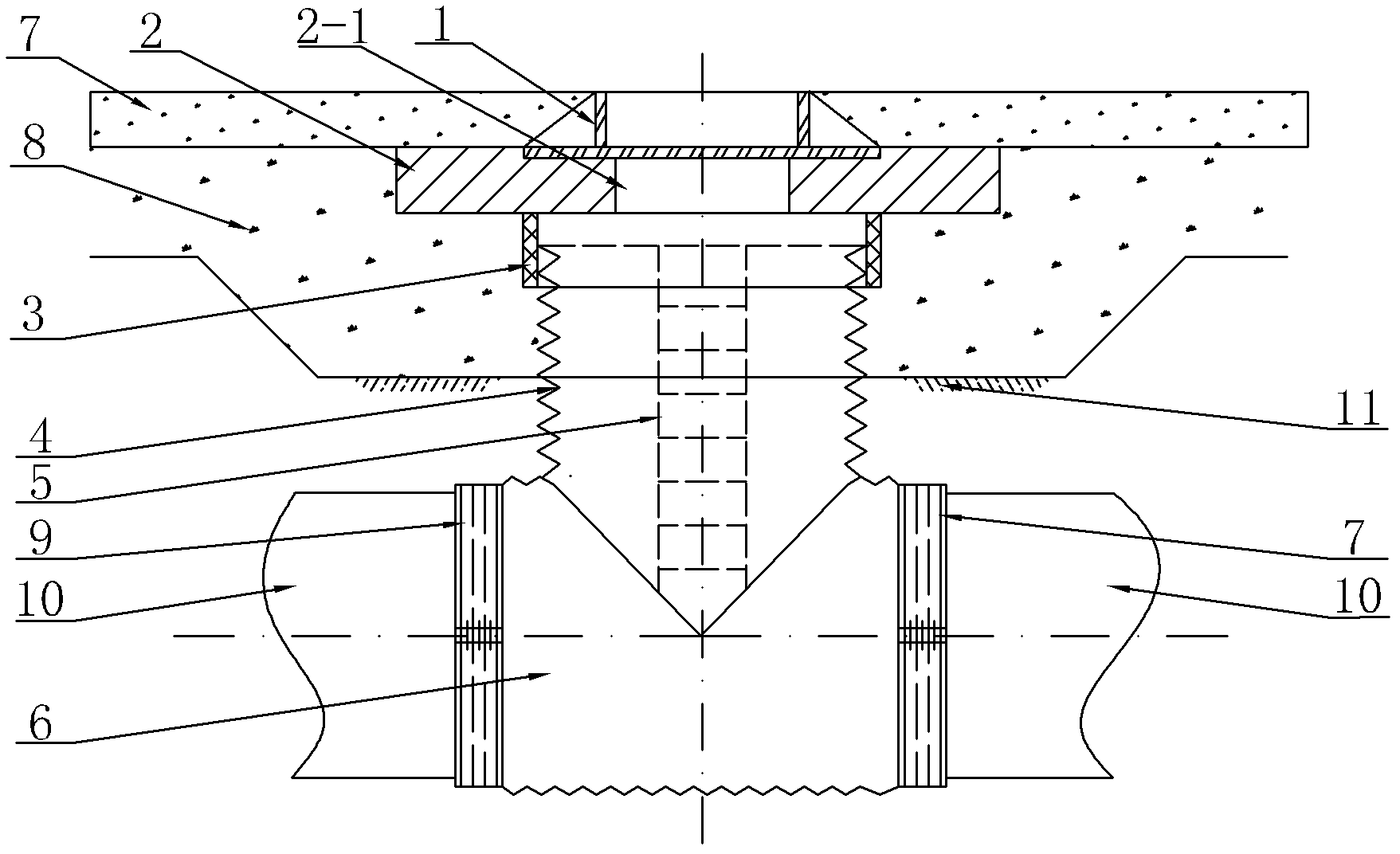

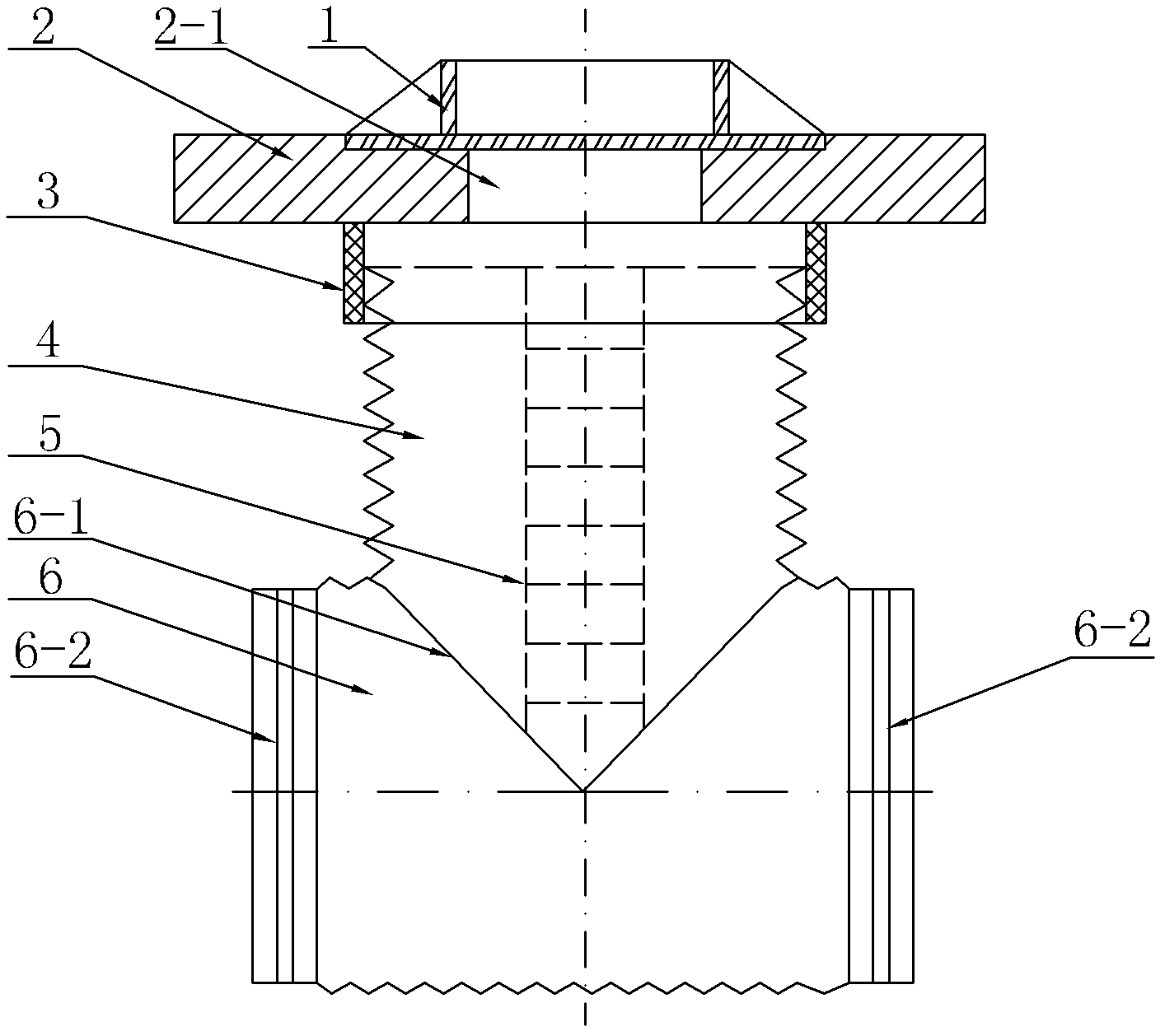

[0007] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, an inspection well of this embodiment includes a well cover 1 and a base 2, the well cover 1 is embedded on the base 2, and the middle part of the base 2 is provided with a wellhead 2-1, which also includes a retaining ring 3, a well shaft 4 and the receiving pipe 6, the wellbore 4 is a bellows made of metal, the receiving pipe 6 is a bellows made of metal, the inner and outer walls of the wellbore 4 and the inner and outer walls of the receiving pipe 6 have The galvanized layer, the wellbore 4 is vertically set, the retaining ring 3 is set on the wellbore 4, the base 2 is set on the upper end surface of the retaining ring 3, the wellhead 2-1 and the wellbore 4 are coaxially arranged, and the pipe wall of the receiving pipe 6 There is a connecting hole 6-1 on the top, and the lower end of the wellbore 4 is set on the connecting hole 6-1 of the receiving pipe 6. The wellbore 4 an...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the inspection well described in this embodiment further includes a foot ladder 5 , and a foot ladder 5 is provided on the inner side wall of the shaft 4 . With such arrangement, it is convenient to use, convenient to inspect and dredge the pipeline, and convenient for construction work. Others are the same as in the first or second embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 To describe this embodiment, the cross-sectional shape of the connecting hole 6-1 on the receiving pipe 6 described in this embodiment is triangular. In this way, the fluidity of the sewage is good and the resistance is small, which meets the design requirements and actual needs. In this embodiment, the connection hole with a triangular cross-sectional shape and the wellbore has a transitional arc, and the others are the same as the specific embodiment 1 or 2.

[0011] work process

[0012] combine figure 1 with figure 2 Illustrate the working process of the present invention. When the inspection well of the present invention is in use, place the integrally made receiving pipe 6 and part of the pipe section of the shaft 4 below the backfill 11, and place the nozzles 6-2 at both ends of the receiving pipe 6 respectively. It is connected with the pipeline 10 buried underground through the clamp 9, and the retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com