Sleeper for track skeleton and method for manufacturing sleeper

A sleeper and rail row technology, which is applied in the field of sleepers for medium and low-speed maglev train rail rows, can solve the problems of complex processing and manufacturing, low production efficiency, and high manufacturing cost, and achieve the effects of low manufacturing cost, simple structure, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

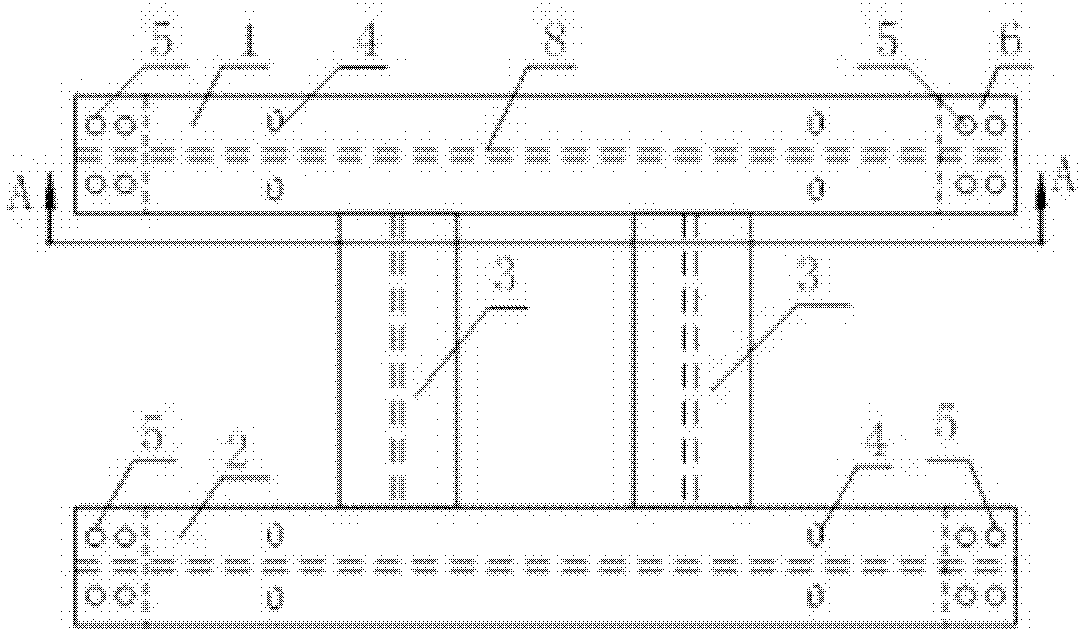

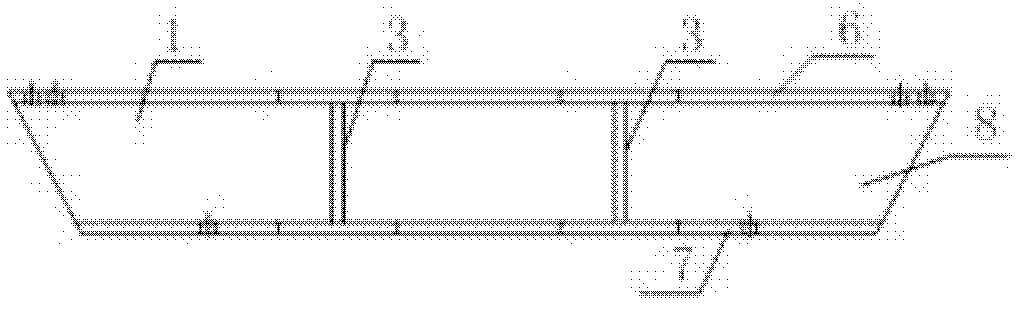

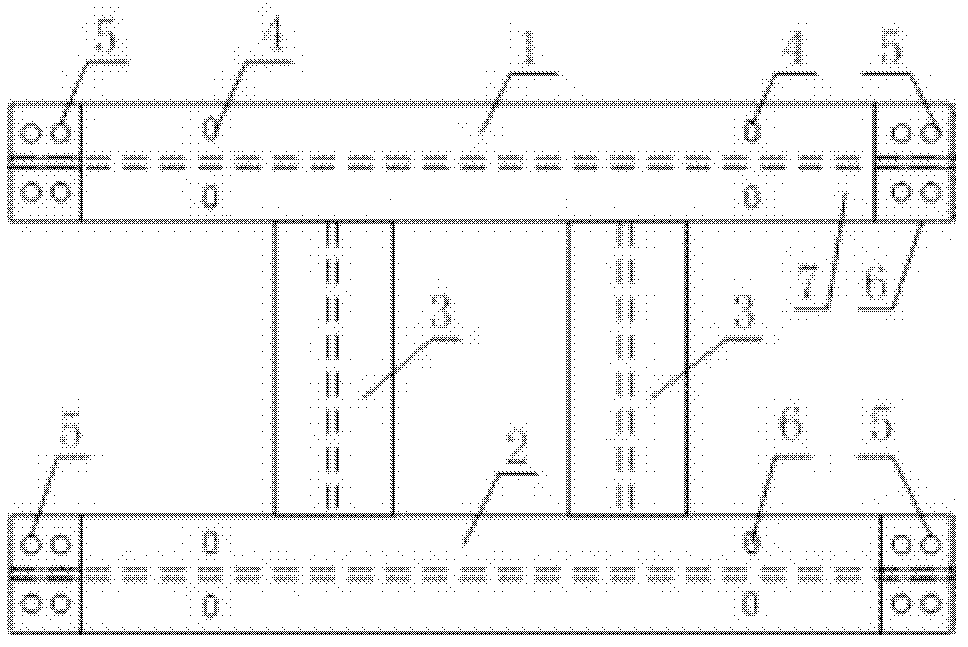

[0039] like figure 1 , figure 2 and image 3 As shown, a sleeper for the track row of a medium-low speed maglev train is welded by two H-shaped steels at the front and rear and a pair of H-shaped steels in the middle, and is characterized in that: the two H-shaped steels at the front and rear are respectively processed into the front H-shaped steel sleeper 1 and The rear H-shaped steel sleeper 2 has two short H-shaped steel 3 welded at the middle position of the front H-shaped steel sleeper 1 and the rear H-shaped steel sleeper 2; The length is 1 / 6 of the length of the lower flange, and two oval or circular anchor bolt holes 4 are processed on both sides of the H-shaped steel web 8, which are fixed on the foundation by bolts, such as figure 1 , figure 2 and image 3 shown. Four circular F-rail bolt holes 5 are symmetrically processed on both sides of the upper flange 6 of the front H-shaped steel sleeper 1 and the rear H-shaped steel sleeper 2. track connection. The d...

Embodiment 2

[0049] like Figure 4 , Figure 5 and Figure 6 As shown, a sleeper for the rail row of a medium-low speed maglev train consists of a front steel pipe sleeper 1A and a rear steel pipe sleeper 2A, and two square steel pipes 3A are welded at the middle position of the front steel pipe sleeper 1A and the rear steel pipe sleeper 2A ; An oval or circular anchor bolt hole 4 is respectively processed at the center of the bottom surface 7A of the front steel pipe sleeper 1A and the rear steel pipe sleeper 2A. bolted to the foundation, such as Figure 4 , Figure 5 and Figure 6 shown. On the top 6A of the front type steel pipe sleeper 1A and the rear type steel pipe sleeper 2A, 4 circular F-rail bolt holes 5 are respectively symmetrically processed with a distance of 100mm from the end to connect with the left and right F-shaped steel rails. The specific positions are determined by the professional technicians. Design OK. The foundation is a track beam, a support structure of c...

Embodiment 3

[0058] The difference from Example 2 is that the two short square steel pipes 3A are replaced by two short H-shaped steels 3 .

[0059] The sleeper material of the present invention is made of Q345 carbon structural steel.

[0060] Others are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com