Azo compound containing phenylindole, preparation method and application thereof

A technology of azo compound and phenyl indole, which is applied in the field of phenyl indole-containing azo compound and its preparation, can solve the problems of unsatisfactory light fastness of azo disperse dyes and cannot be taken into account, and achieve excellent light fastness degree, satisfactory washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

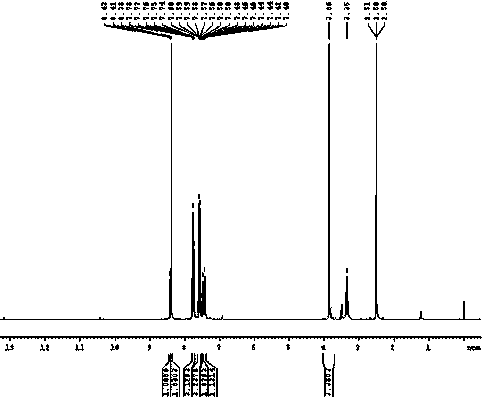

Embodiment 1

[0040] (1) Add 120g of 98% sulfuric acid and 68g of 40% nitrosylsulfuric acid into the flask, stir for 1 hour, control the temperature at 25°C, add 41.4g (0.2mol) of 2,6-dichloro-4-nitrate under stirring Base aniline, heat preservation reaction for about 5 hours, diazotization is completed, add 400g ice water, add the above-mentioned diazonium salt under stirring to dilute;

[0041] (2) Add 1.2g of 10#OP to the diazonium salt dilution in step (1);

[0042] (3) Add 330g of 98% sulfuric acid to another flask, control the temperature at 25°C, add a total of 41.4g of N-methyl-2-phenylindole under stirring, keep it warm for 2 hours to completely dissolve, and wait for coupling.

[0043]Add the dissolved N-methyl-2-phenylindole slowly at 4°C to the diazonium salt diluent with emulsifier added in step (2) for coupling reaction, keep warm for 5 hours until coupling After the reaction is completed, the temperature is raised to 70° C., kept for 2 hours, and then filtered, and the filte...

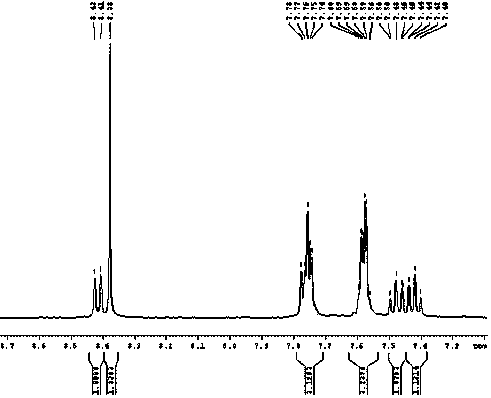

Embodiment 2

[0046] (1) Add 90g of 98% sulfuric acid and 173g of 40% nitrosylsulfuric acid into the flask, stir for 0.5 hours, control the temperature at 35°C, add 148g (0.5mol) of 2,6-dibromo-4-nitro under stirring Aniline, heat preservation reaction for about 2 hours, diazotization is completed, then add 1200g of ice water, add the above-mentioned diazonium salt under stirring to dilute;

[0047] (2) Add 1g of 8#OP to the diazonium salt dilution in step (1);

[0048] (3) Add 860g of sulfuric acid with a mass concentration of 75% to another flask, control the temperature at 15°C, add 121.5g of N-ethyl-2-phenylindole under stirring, keep it warm for 5 hours to completely dissolve, and wait for coupling.

[0049] Slowly add the above-mentioned dissolved N-ethyl-2-phenylindole to the diazonium salt dilution solution with emulsifier added in step (2) at 0°C for coupling reaction, and keep warm for 5 hours until coupling After the reaction is completed, the temperature is raised to 60° C., ke...

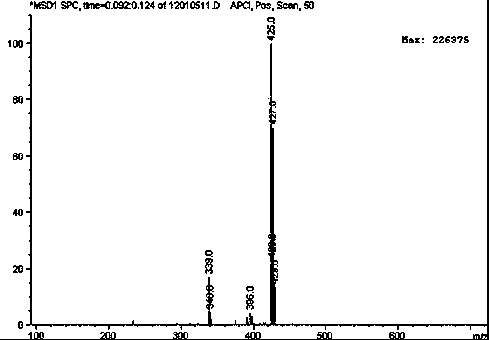

Embodiment 3

[0053] (1) Add a total of 140 g of 60% sulfuric acid solution into the reaction vessel, add 16.8 g (0.2 mol) of 3-amino-1,2,4-triazole under stirring, and beat at 10°C for 3.0 hours. Cool down to 5°C, add a total of 46g of 32% sodium nitrite solution at this temperature, keep stirring at 5°C for 1 hour to prepare diazonium salt, then add 520g of ice water for dilution, and set aside.

[0054] (2) Add 0.8g of 10#OP to the diazonium salt dilution in step (1);

[0055] (3) Add 305g of 98% sulfuric acid to the flask, control the temperature at 20°C, add a total of 38.6g of 2-phenylindole under stirring, keep it warm for 2 hours to completely dissolve, and wait for coupling.

[0056] Slowly add the above dissolved 2-phenylindole sulfuric acid solution into the diazonium salt diluent with emulsifier added prepared in step (2), control the temperature at 5°C, and keep the reaction for 5 hours until the coupling reaction is completed. After the reaction, raise the temperature to 75°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com