Device and method for producing toughened glass

A technology of tempered glass and production equipment, which is applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of difficulty in achieving complete tempering of ultra-thin glass, high noise, and high power consumption, and achieve low noise and reduced The effect of low energy consumption and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

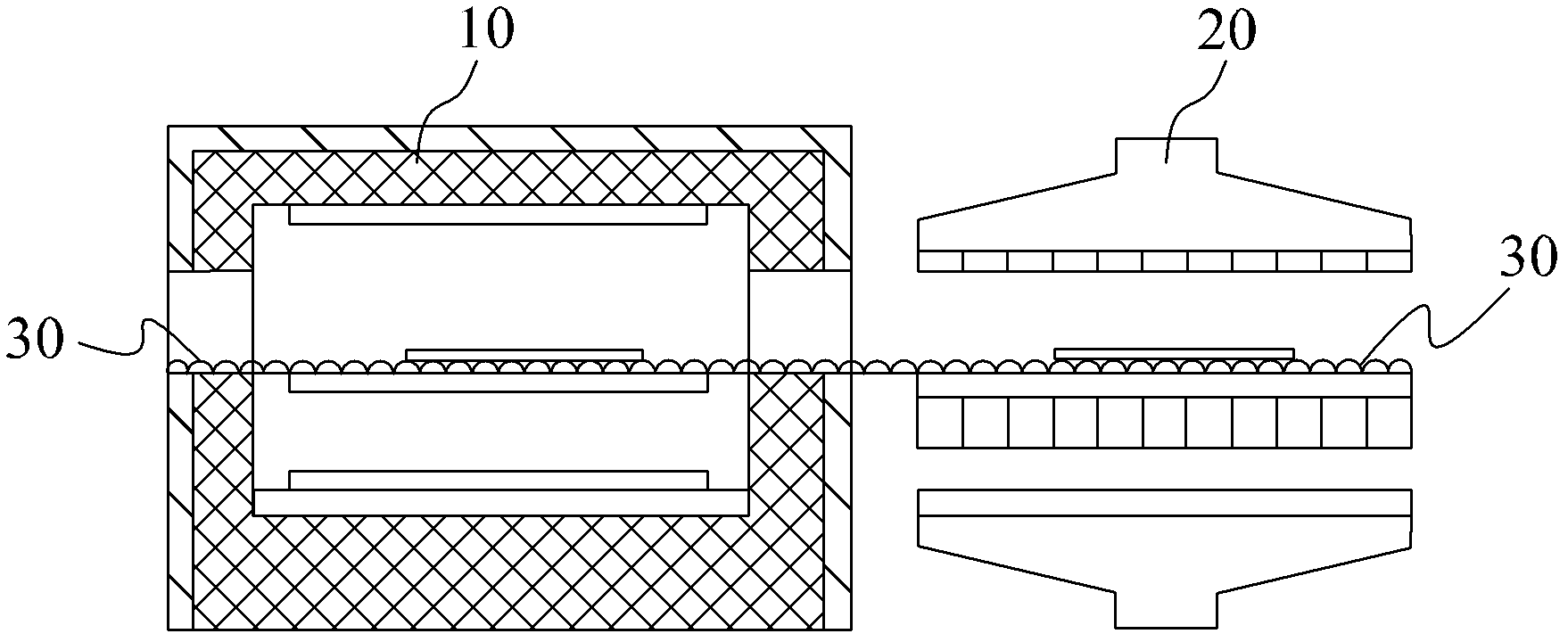

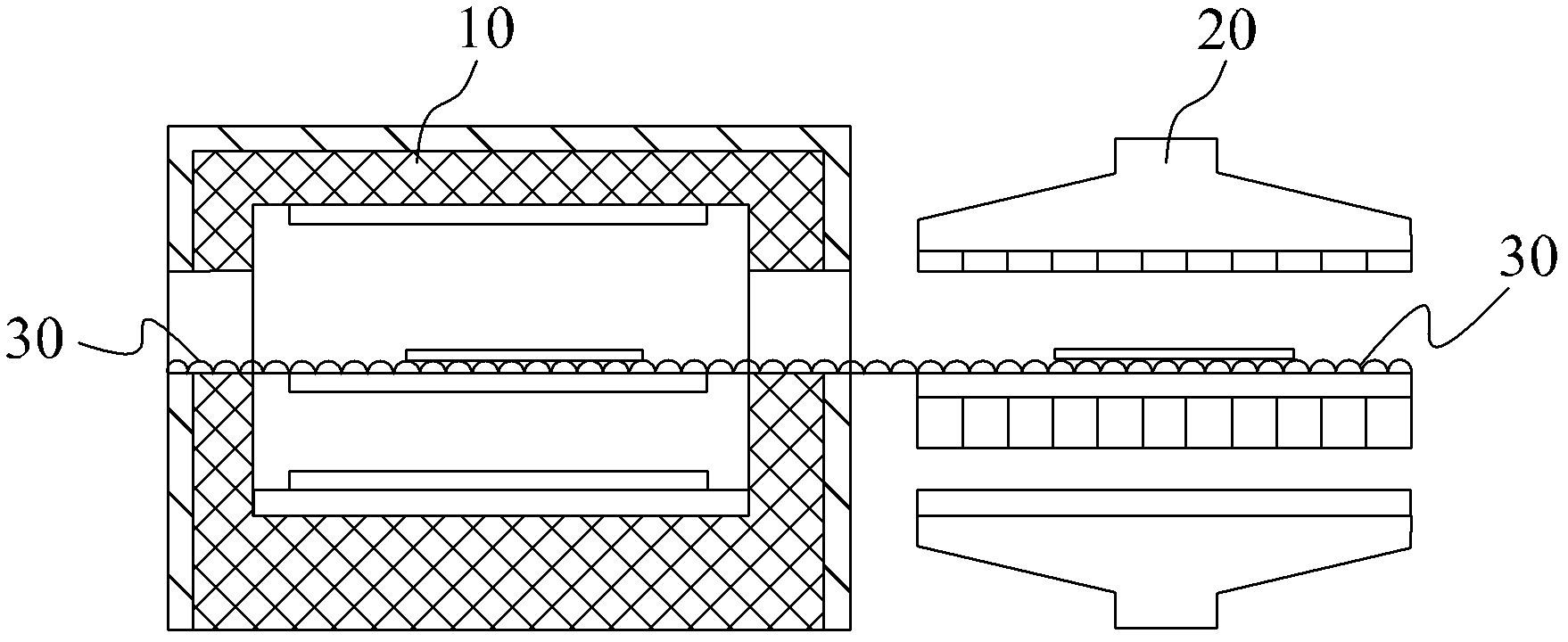

[0029] Such as figure 1 As shown, the tempered glass production device of the present invention includes a heating device 10, a tempering device 20, and a roller table device 30 connected between the heating device 10 and the tempering device 20, and the roller table device 30 is used for heating device 10 and tempering device 20. Glass substrates are transported between apparatuses 20 .

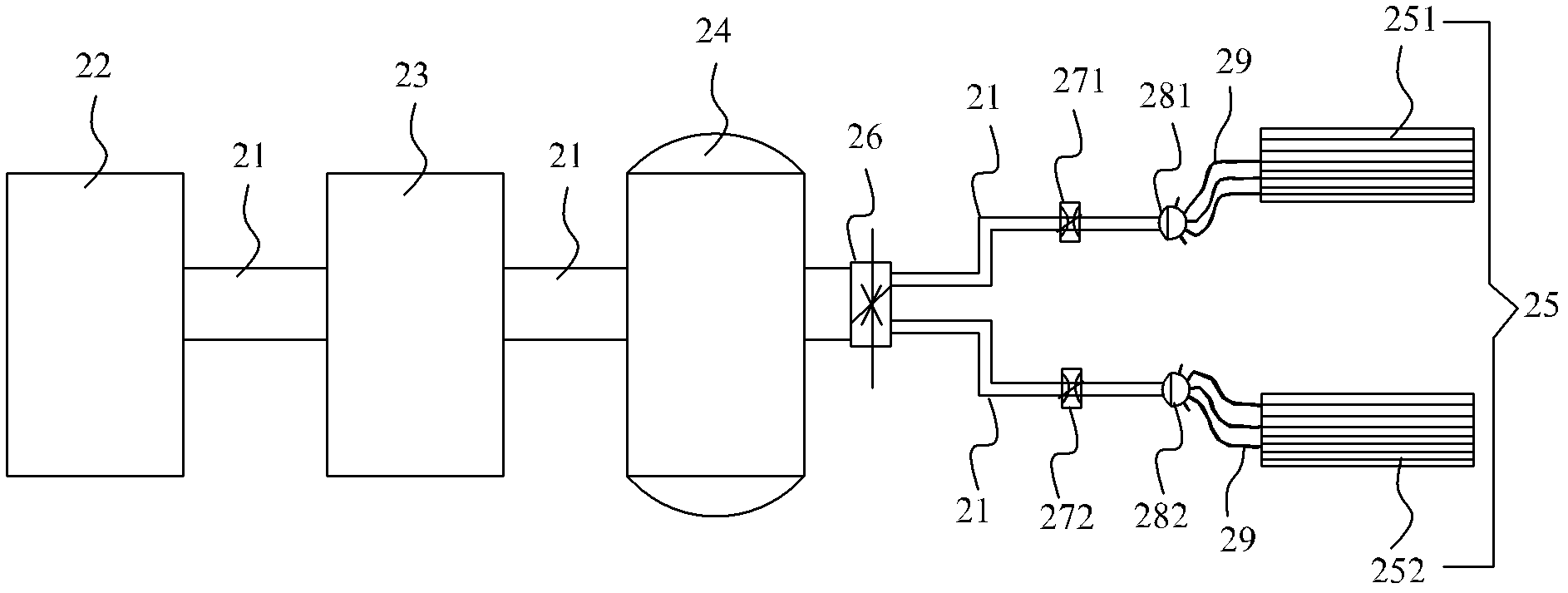

[0030] Such as figure 2 As shown, the tempering device 20 includes a screw air compressor 22 , an air filter 23 , an air storage tank 24 and a quenching air grid 25 connected in sequence by an air supply pipeline 21 . An automatic air volume regulating valve 26 is provided at the output end of the air storage tank 24, so that the air pressure and air volume of the tempered air grid can be adjusted according to the thickness of the glass substrate to reduce unnecessary energy consumption. The quenching air grid 25 includes a first quenching air grid 251 and a second quenching air grid 252 ...

Embodiment 2

[0032] Take a glass substrate with a thickness of 2-3mm, put it in the heating device 10 and heat it to 680°C-700°C; pass the roller table device 30, and transport the heated glass substrate to the tempering device 20 within 1-2 seconds , and place the glass substrate between the first quenching air grid 251 and the second quenching air grid 252 for instantaneous high-pressure air quenching treatment, and the distances between the glass substrate and the first and second quenching air grids are respectively 5 mm to 10mm, the quenching air pressures output by the first and second quenching air grids are respectively 200kPa-300kPa, and the quenching time is 1-2 seconds. The screw air compressor 22 is intermittently working, as long as the air pressure in the air storage tank 24 is kept above 800kPa, the air volume output by the first and second quenching air grids can be adjusted by adjusting the automatic air volume regulating valve 26. The pressure reaches 200kPa ~ 300kPa, and...

Embodiment 3

[0034]Take a glass substrate with a thickness of 2mm, place it in the heating device 10 and heat it to 680°C-690°C; pass through the roller table device 30, transport the heated glass substrate to the tempering device 20 within 1-2 seconds, and The glass substrate is placed between the first quenching air grid 251 and the second quenching air grid 252 for instantaneous high-pressure air quenching treatment, and the distances between the glass substrate and the first and second quenching air grids are respectively 5 mm to 6 mm. The quenching air pressures output by the first and second quenching air grids are respectively 280kPa-300kPa, and the quenching time is 1-2 seconds. The screw air compressor 22 is intermittently working, as long as the air pressure in the air storage tank 24 is kept above 800kPa, the air volume output by the first and second quenching air grids can be adjusted by adjusting the automatic air volume regulating valve 26. The pressure reaches 280kPa ~ 300kP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com