Method and equipment for recovering machine head material of plastic extruder/injection molding machine on site

A plastic extruder, on-site recycling technology, applied in the direction of plastic recycling and recycling technology, to achieve the effect of saving energy, maintaining the original performance, and reducing the workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

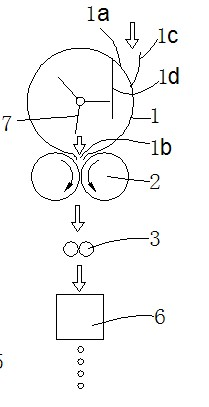

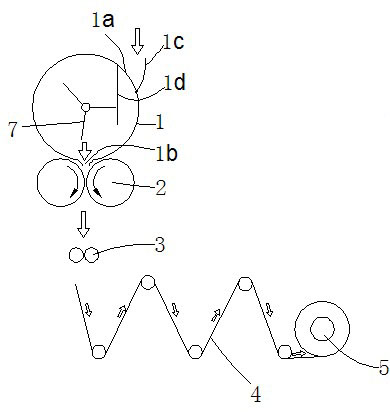

Image

Examples

Embodiment Construction

[0019] A method for on-site recycling of plastic extruder / injection molding machine head material, comprising the following steps:

[0020] a) Heating and heat preservation: Send the head material just out of the extruder / injection molding machine directly into the heating insulation box to maintain or heat it to a high elastic state. The temperature of the head material in the high elastic state is usually 130-180°C ;The head material just out of the extruder / injection molding machine is in a high elastic state. The function of the heating insulation box is to ensure that the head material is still in a high elastic state before the pressing plate. Heating can be manually fed into the heating incubator, or it can be fed by automatic conveyor belt to save labor.

[0021] b) Press plate: Extrude the head material in a highly elastic state into a plate shape through a plate press machine;

[0022] c) Layering: Then the plate-shaped head material is sent to the layering machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com