Dust-free concrete production device and production process of dust-free concrete

A technology of production equipment and production process, which is applied in the field of production technology and concrete production equipment, can solve the problems of easy spillage and leakage of cement dust, achieve the effect of improving the processing site environment, reducing the possibility of pneumoconiosis, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

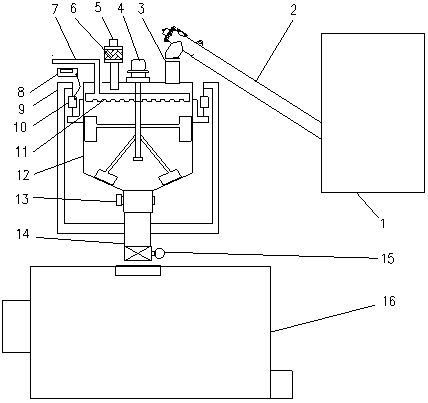

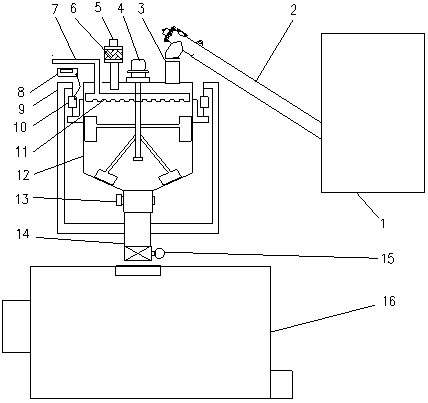

[0026] Choose each component of suitable specification, install and connect as shown in the accompanying drawing, obtain a dust-free concrete production device of the present invention. The device includes a powder storage bin 1, a screw powder conveyor 2, a water supply system 7, and also includes a mixer support 9, a weight sensor 10, a slurry mixer 12, and a concrete mixer 16. The slurry mixer 12 includes a powder input port 3, a water inlet 11, a stirring mechanism 4, a dust filter 6, an exhaust port 5, and a discharge port 13. The slurry mixer 12 is suspended on the mixer bracket 9 through the weight sensor 10, and the weight sensor 10 is connected with a weight display device 8; the dust filter device 6 is movably connected to cover the exhaust port 5 of the slurry mixer 12, and the dust filter device 6 has a built-in paper Dust-absorbing material; the discharge port 13 is connected with a valve 14, or is also connected with an output pump 15.

[0027] The concrete mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com