High-voltage live working robot device

A working robot, high-voltage live technology, applied in cable installation devices, cable installation, manipulators, etc., can solve problems such as low work efficiency and automation level, high labor intensity of manual live work, personal casualties, etc., and achieves three-dimensional insulation. Protection system, avoid human and machine casualties, improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

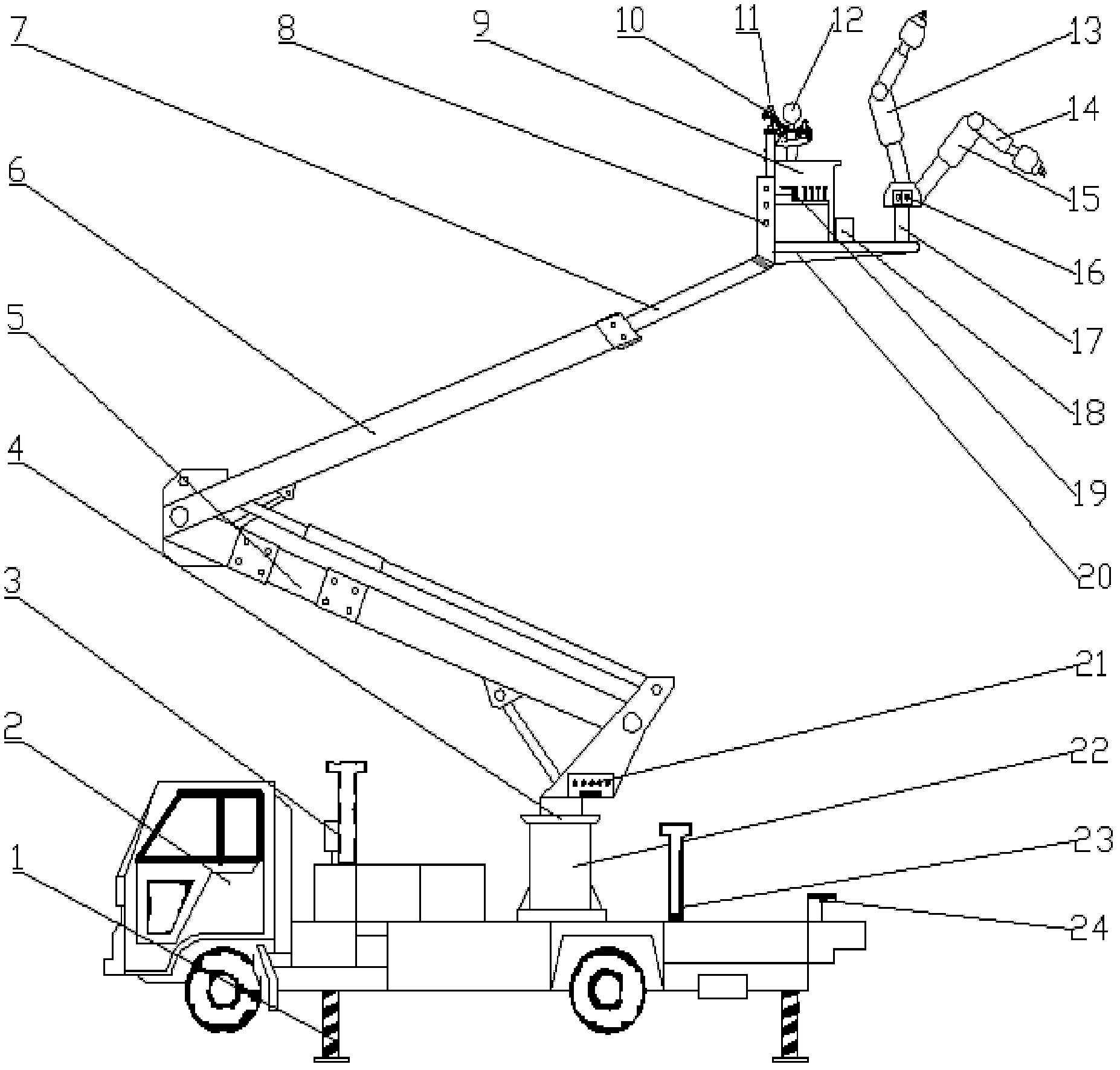

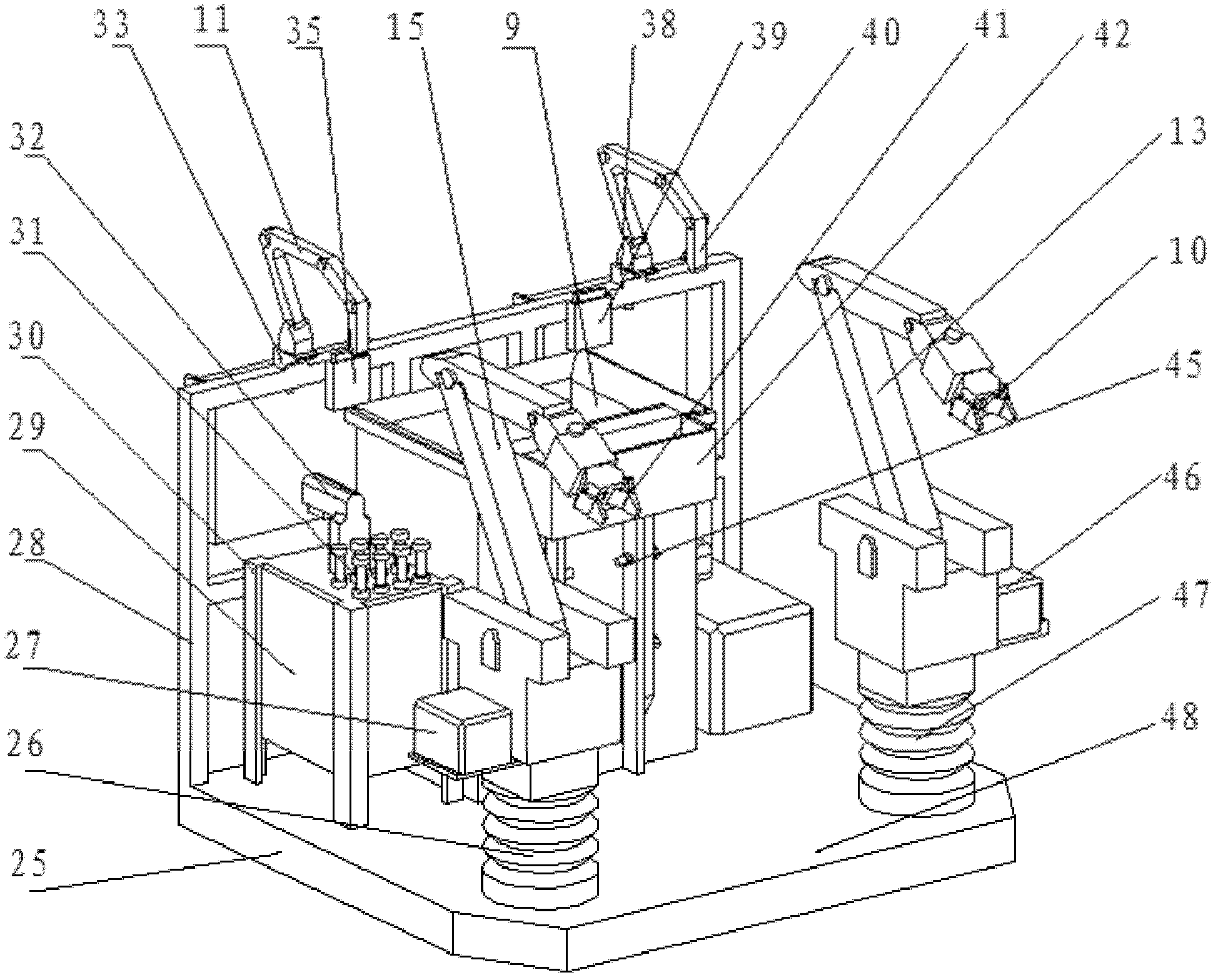

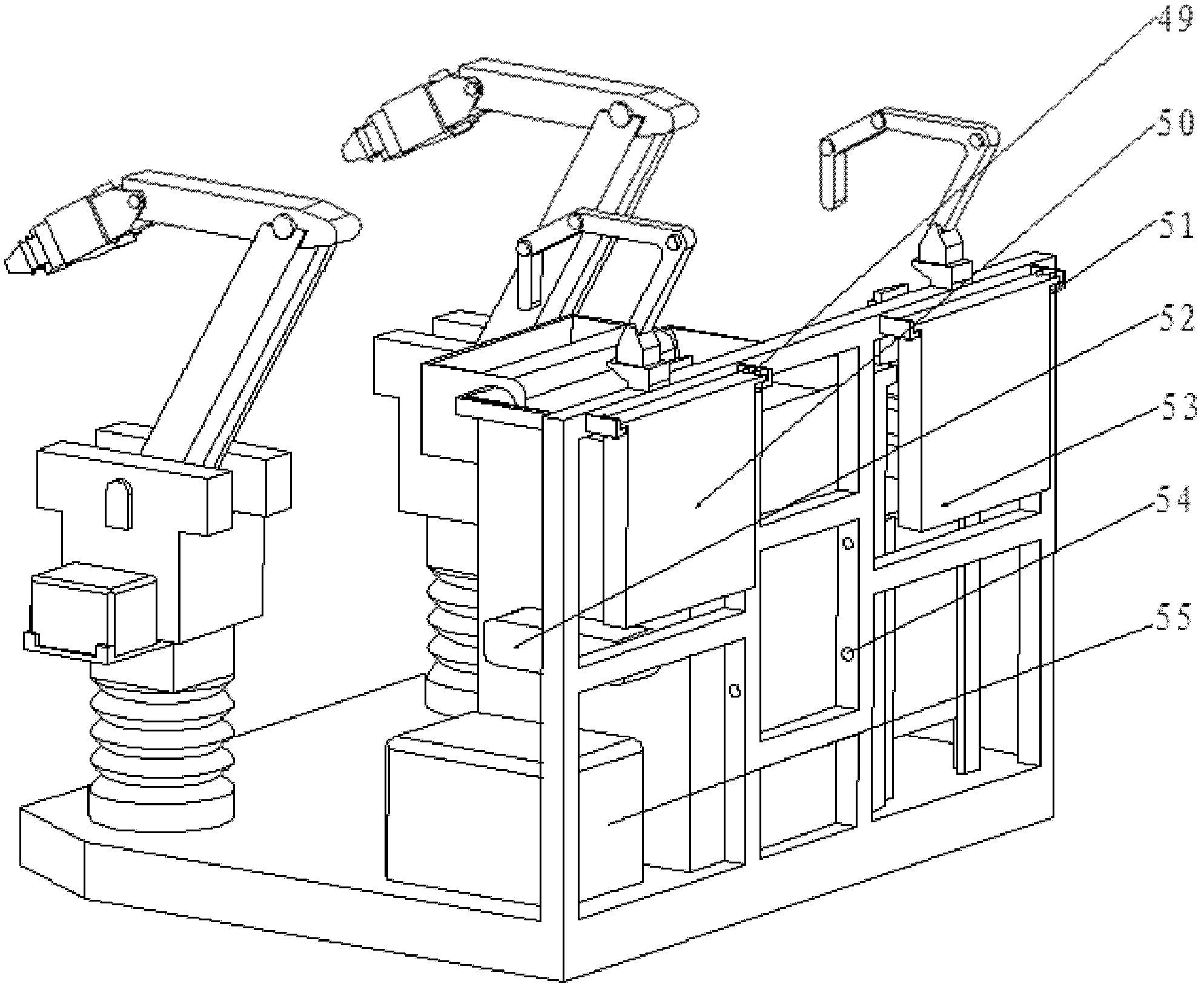

[0033] combine figure 1 , a high-voltage live working robot device, including a mobile car 2, a top-mounted folding and telescopic insulating arm, a top-mounted control device and a robot operating platform.

[0034] Mobile car 2 chassis are provided with lower arm support frame 3, upper arm support frame 23, robot work platform support frame 24, supporting leg 1. The upper folding and telescopic insulating arm is arranged on the chassis of the mobile car 2, and the upper folding and telescopic insulating arm includes an upper hydraulic pump station 22, a slewing tower 4, a lower arm 5, an upper arm 6, a telescopic arm 7, and the telescopic arm 7 is connected with the robot operation platform by bolt 8.

[0035] The upper control device includes a lower control device 21 and an upper control device 19. The lower control device is arranged on the slewi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com