Composite catalyst for lead acid battery, and preparation method of composite catalyst

A technology for composite catalysts and lead-acid batteries, applied in lead-acid batteries, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reducing battery internal pressure, accelerating decomposition speed, etc., and achieves easy scale-up and preparation process Simple, low loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

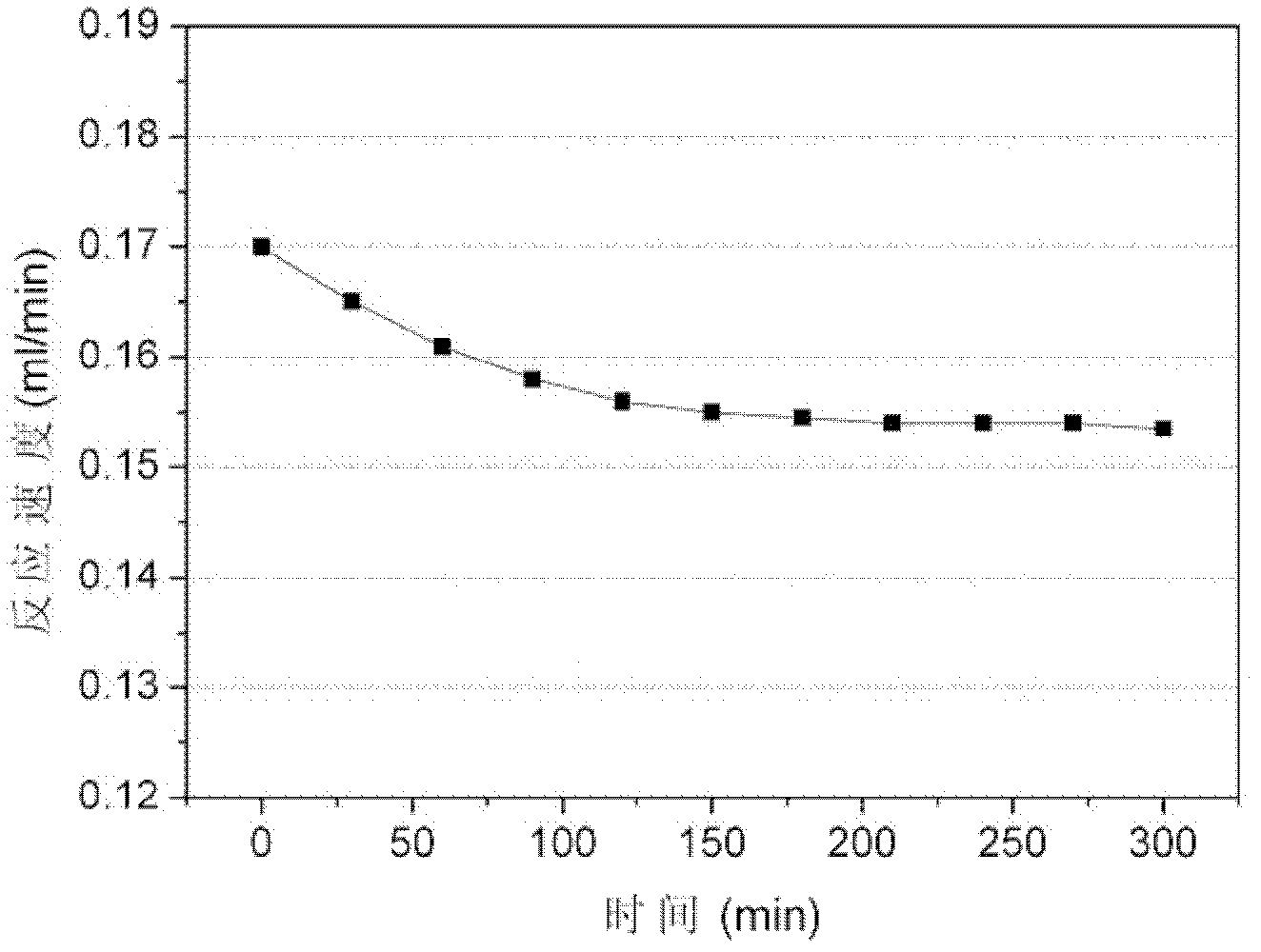

Image

Examples

Embodiment 1

[0021] Embodiment 1 0.2%PtPd / C catalyst preparation

[0022] Granular activated carbon is used as the carrier, and the mass ratio of Pt and Pd is 1:1. The specific preparation process is as follows:

[0023] (1) configure the ethylene glycol solution of chloroplatinic acid and palladium chloride, chloroplatinic acid and palladium chloride are analytically pure, in the present embodiment, weigh 1g chloroplatinic acid solution and 0.5g palladium chloride respectively, And be prepared into 1000ml respectively, concentration is the chloroplatinic acid / ethylene glycol solution of 1mg / ml and 1000ml, concentration is the palladium chloride / ethylene glycol solution of 0.5mg / ml;

[0024] (2) configure sodium hydroxide / ethylene glycol solution and hydrochloric acid / ethylene glycol solution, in the present embodiment, weigh 16g sodium hydroxide and 20ml hydrochloric acid, add 200ml ethylene glycol respectively, obtain the hydroxide of 2mol / L Sodium / ethylene glycol solution and 3mol / L hy...

Embodiment 2

[0031] Embodiment 2 0.5%Pd / C catalyst preparation

[0032] Granular activated carbon is used as the carrier, and the specific preparation process is as follows:

[0033] (1) configure the ethylene glycol solution of palladium chloride, palladium chloride is analytically pure, take 2g palladium chloride by weighing, be mixed with 1000ml, the palladium chloride / ethylene glycol solution that concentration is 2mg / ml;

[0034] (2) configure sodium hydroxide / ethylene glycol solution and hydrochloric acid / ethylene glycol solution, in the present embodiment, weigh 16g sodium hydroxide and 20ml hydrochloric acid, add 200ml ethylene glycol respectively, obtain the hydroxide of 2mol / L Sodium / ethylene glycol solution and 3mol / L hydrochloric acid / ethylene glycol solution;

[0035] (3) Weigh 5g of granular activated carbon carrier, and add 1000ml of ethylene glycol, and stir with a stirrer to obtain slurry A;

[0036] (4) Pipette 21.5ml palladium chloride / ethylene glycol solution, and joi...

Embodiment 3

[0041] Embodiment 3 1.0%Pt / C catalyst preparation

[0042] Granular activated carbon is used as the carrier, and the specific preparation process is as follows:

[0043] (1) configure the ethylene glycol solution of chloroplatinic acid, chloroplatinic acid is analytically pure, take 8g chloroplatinic acid by weighing, be mixed with the chloroplatinic acid / ethylene glycol solution that 1000ml concentration is 8mg / ml;

[0044](2) configure sodium hydroxide / ethylene glycol solution and hydrochloric acid / ethylene glycol solution, in the present embodiment, weigh 16g sodium hydroxide and 20ml hydrochloric acid, add 200ml ethylene glycol respectively, obtain the hydroxide of 2mol / L Sodium / ethylene glycol solution and 3mol / L hydrochloric acid / ethylene glycol solution;

[0045] (3) Weigh 5g of granular activated carbon carrier, and add 1000ml of ethylene glycol, and stir with a stirrer to obtain slurry A;

[0046] (4) Pipette 17ml palladium chloride / ethylene glycol solution, and joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com