Corneal thickness measuring method based on subdivision of pulses

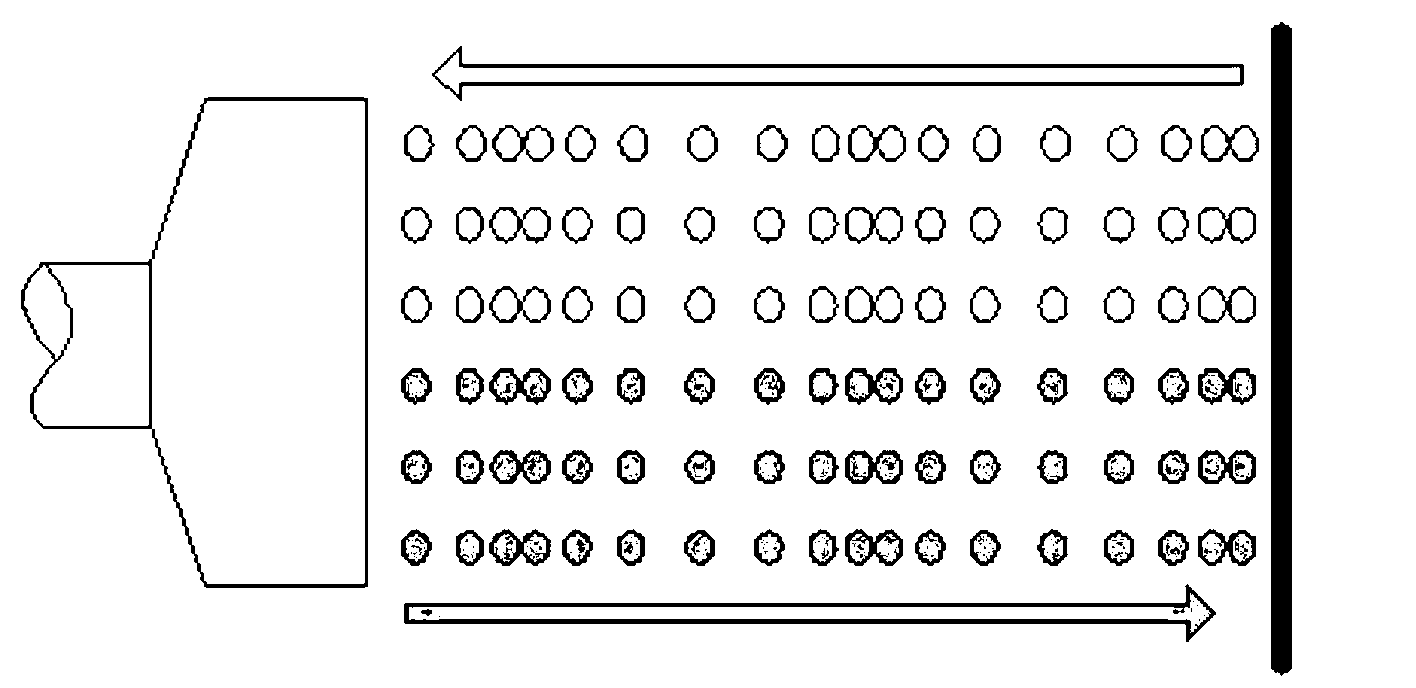

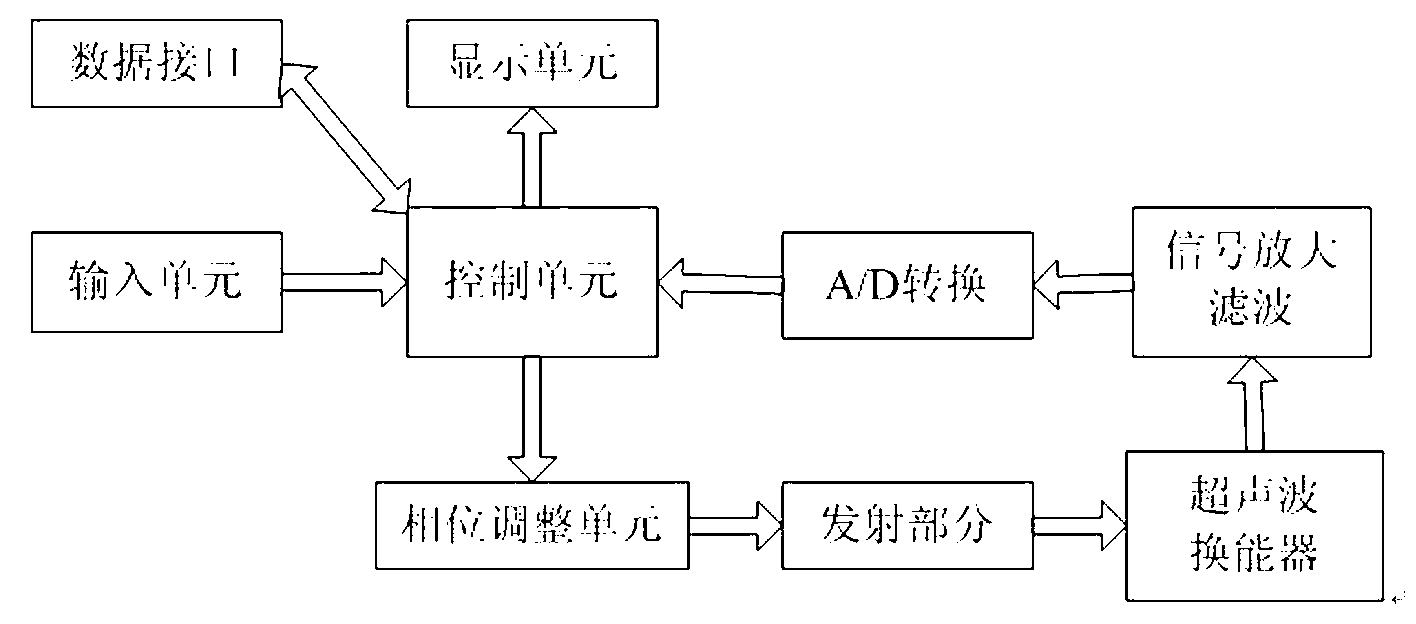

A technology of corneal thickness and measurement method, which is applied in the direction of eye testing equipment, eye examination, etc., can solve the problems of the center frequency limitation of the resolution emission wave, etc., and achieve the effect of high resolution and easy popularization and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment, further illustrate the present invention.

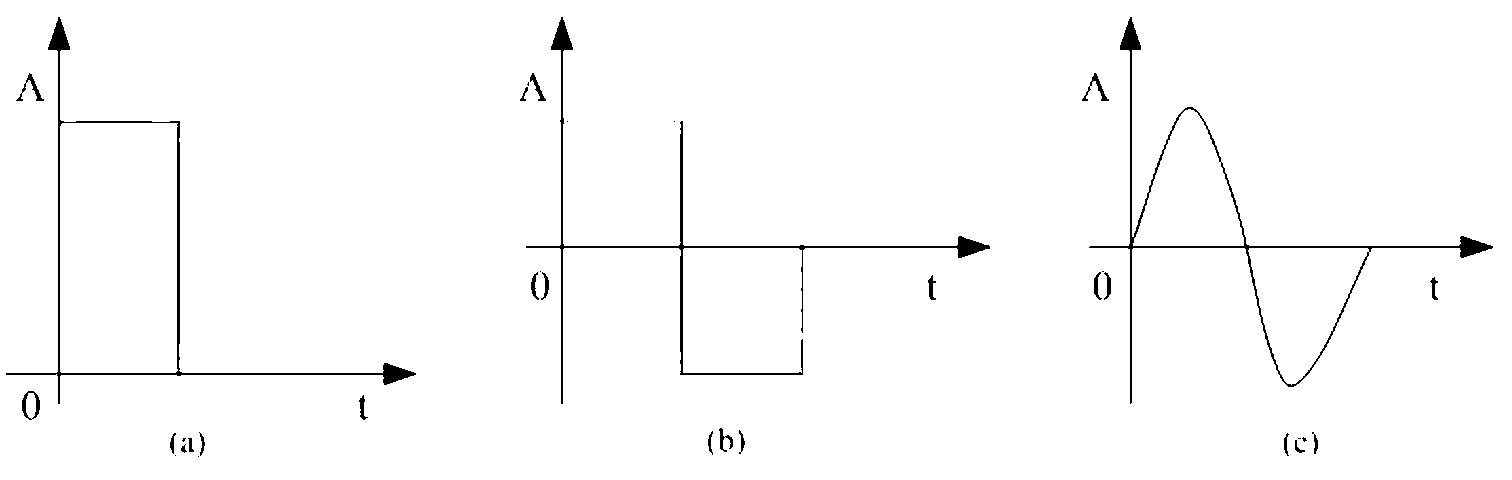

[0018] Example transmit waveforms are in the form of simple harmonics ,Right now

[0019]

[0020] In the formula ω , φ are the angular frequency and the initial phase, respectively. The received reflected wave is modulated by the medium, and the reflection characteristic of the medium is defined as R(x), and the form of the echo can be recorded as:

[0021]

[0022] If the value of the echo reaches the maximum R(x) maximum while Equal to 1 or -1. R(x) The maximum means the reflected echo of the interface, by adjusting the initial phase φ It can make the ultrasonic wave reach the interface at the moment when the sound pressure is maximum. If the subdivision phase is Φ , then in addition to the integer multiples of the half-wavelength in the distance, there are also Φ / π fractional multiples of half-wavelength. The more subdivision steps N, the higher the accuracy. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com