Wire harness rubber ring

A wire harness apron and apron technology, which is applied to electrical components and other directions, can solve the problems of disconnection between the wiring harness and the apron, damage to the bell mouth of the apron, affecting the life of the apron, etc. Service life, the effect of avoiding relative displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

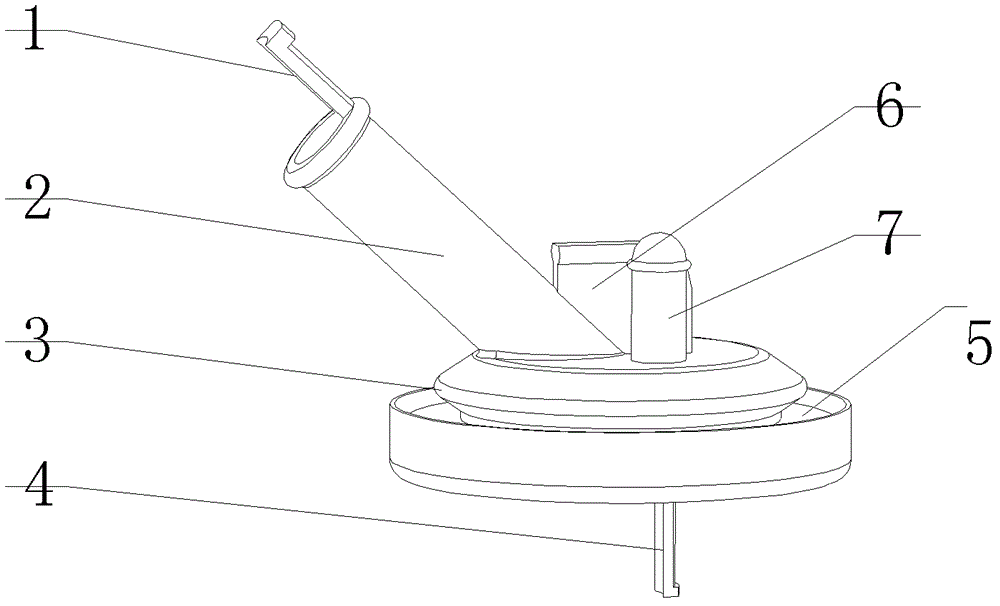

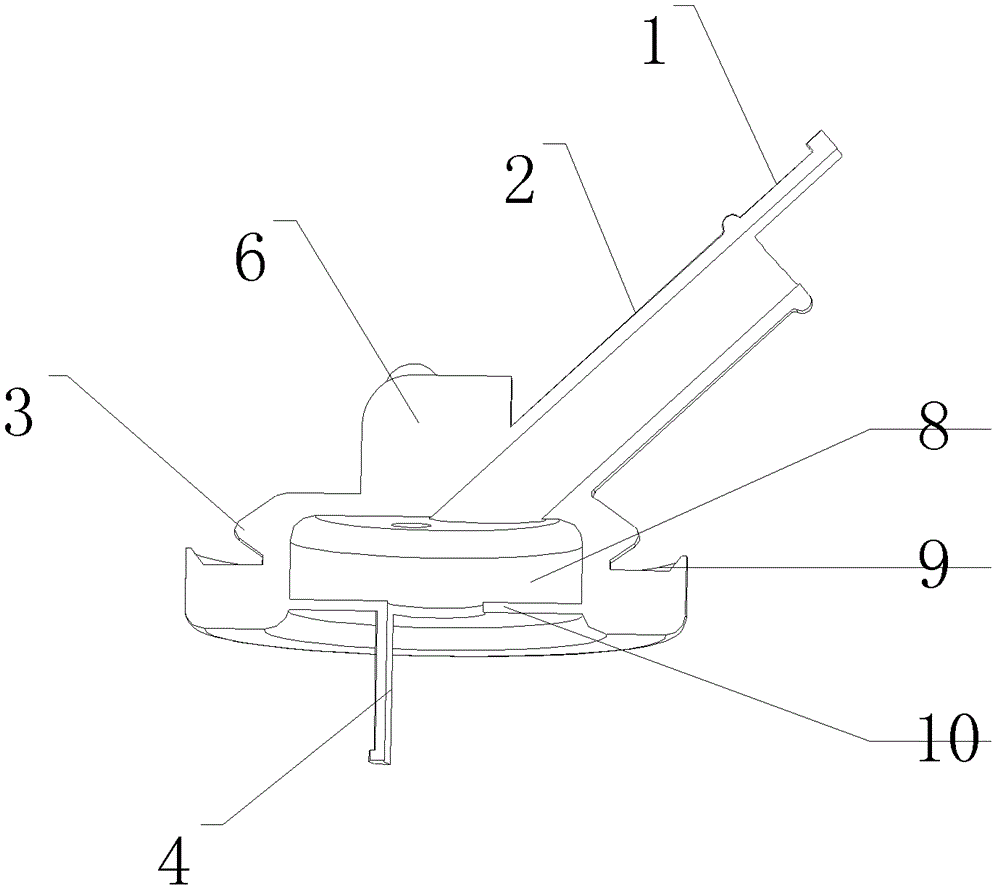

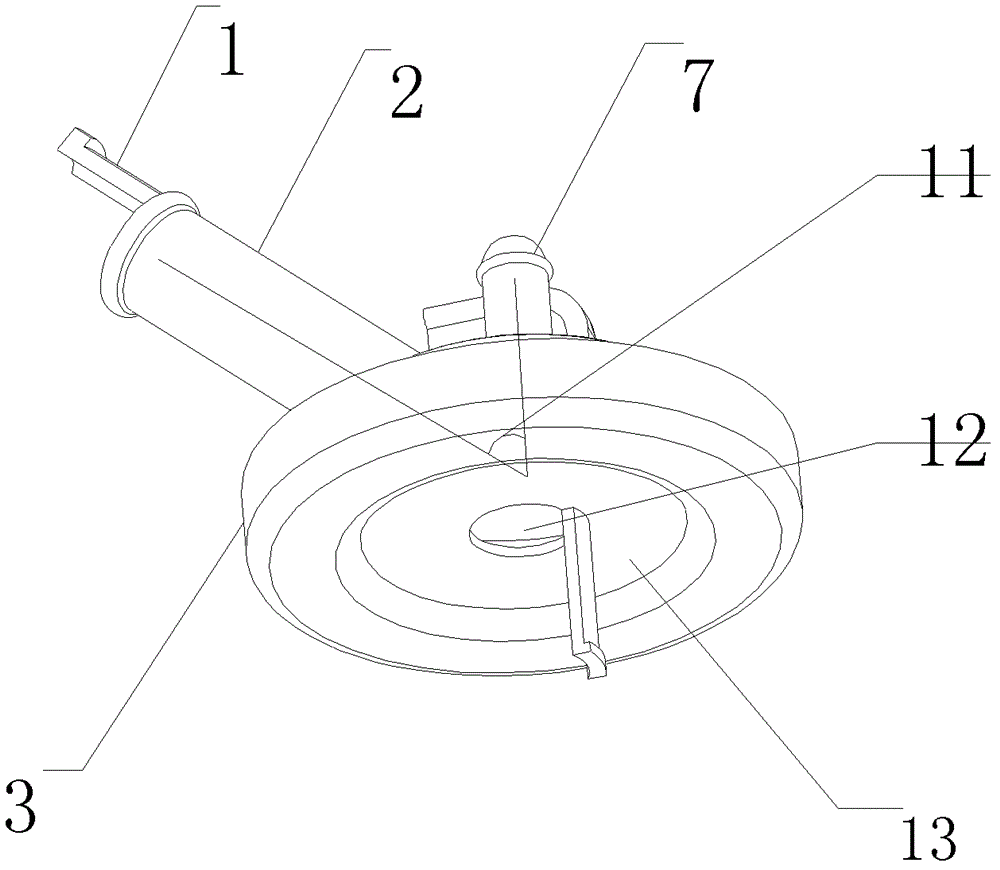

[0024] Such as Figure 1-3 As shown, a wire harness apron according to the embodiment of the present invention includes an apron main body 3, a cavity 8 is provided inside the apron main body 3, and a wire tube 2 and a pull tab are provided on the top of the apron main body 3. 6 and the spare blind hole 7, the bottom of the apron main body 3 is provided with a groove one 13, and the middle part of the groove one 13 is provided with a wire hole 12, and the wire pipe 2 and the wire hole 12 are all communicated with the cavity 8. The wiring harness fixing tongue 1 is connected to the wire passing pipe 2 . The bottom of the wire passing hole 12 is connected with a wire harness fixing tongue 2 4 . Bosses are provided at the ends of the first wire harness fixing tongue 1 and the second wire harness fixing tongue 4 . There is an included angle between the wire passing pipe 2 and the top surface of the rubber ring main body 3 . The spare blind hole 7 and the pull tab 6 are perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com