Soil sealing and guiding thrust plate for horizontal tunnel lining model testbed board

A model test and thrust plate technology, which is applied in the field of thrust plates for tunnel lining model test research, can solve the problems of uneven force on the upper and lower sides of the surrounding rock, uneven force on the surrounding rock, high cost, etc., and achieve the elimination of frictional resistance, Guarantee the effect of accuracy and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

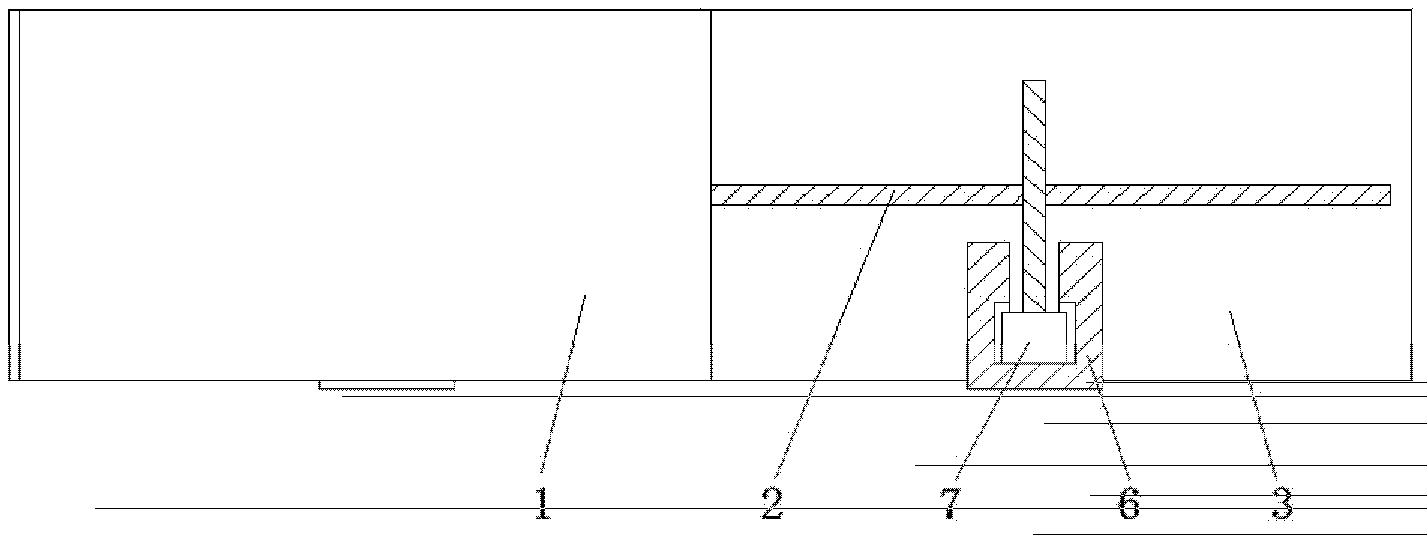

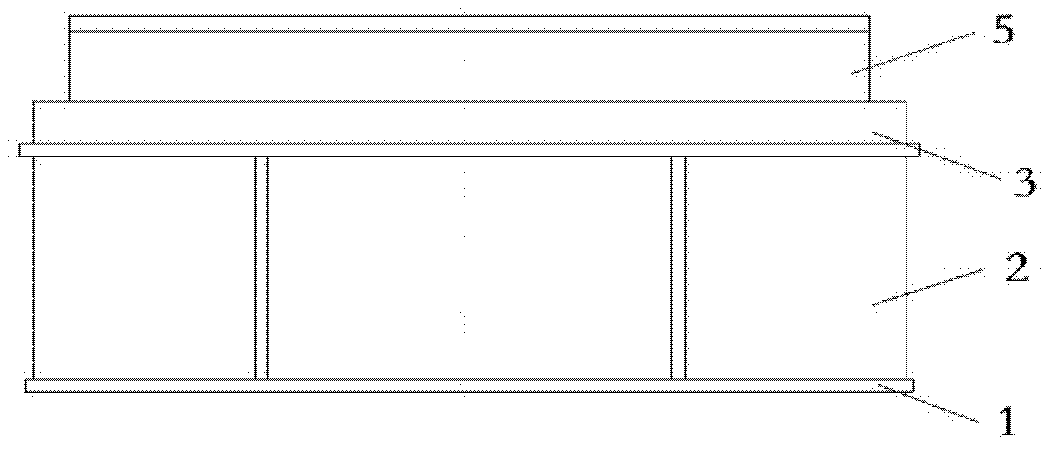

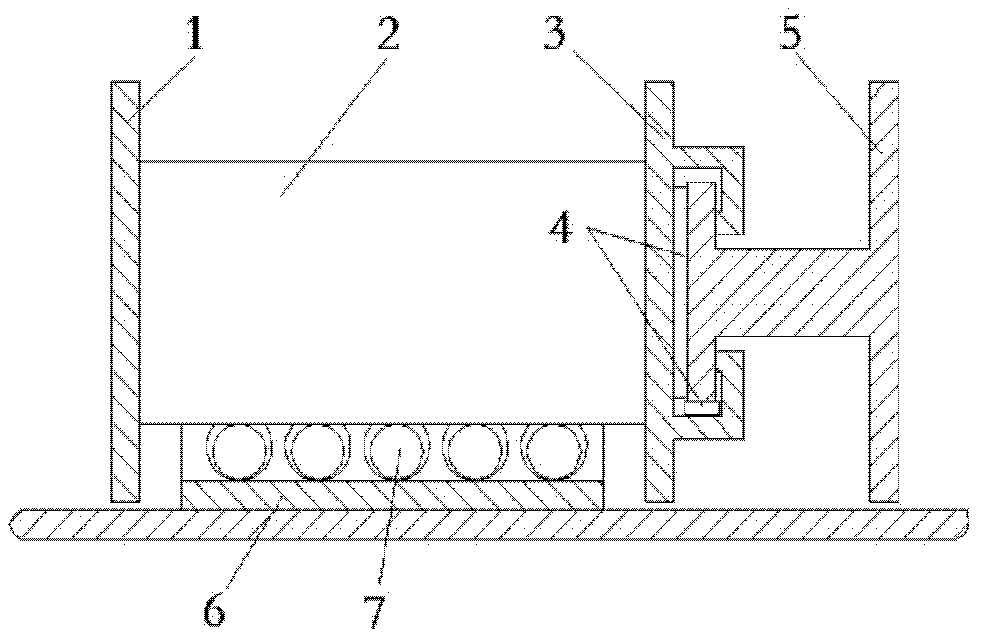

[0019] A specific embodiment of the present invention is shown in the figure. All sealable guide thrust plates are designed to be the same, and are composed of push plate 1, slide plate 5 and "concave" shaped chute 6. Push plate 1 and slide plate 5 can move vertically in the horizontal plane; slide plate 5 can move along the adjacent push plate 1. Move in the direction of force; the vertical lower end surface of the tester is placed in the "concave" shaped groove 6, which is used for the guidance and bearing of the push plate 1, and makes there is a small gap between the push plate 1 and the test table surface. When assembling, all the push plates 1 slide plates protrude a part sequentially from the adjacent slide plates 5 .

[0020] After the push plate 1, the cross rib 2 and the slide plate groove 3 of the present invention are processed according to the drawings, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com