System for testing optical thin film damage threshold

A technology of optical film and test system, which is applied in the direction of testing optical properties, can solve problems such as large measurement errors, and achieve the effects of wide application range, accurate measurement, and accurate data results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

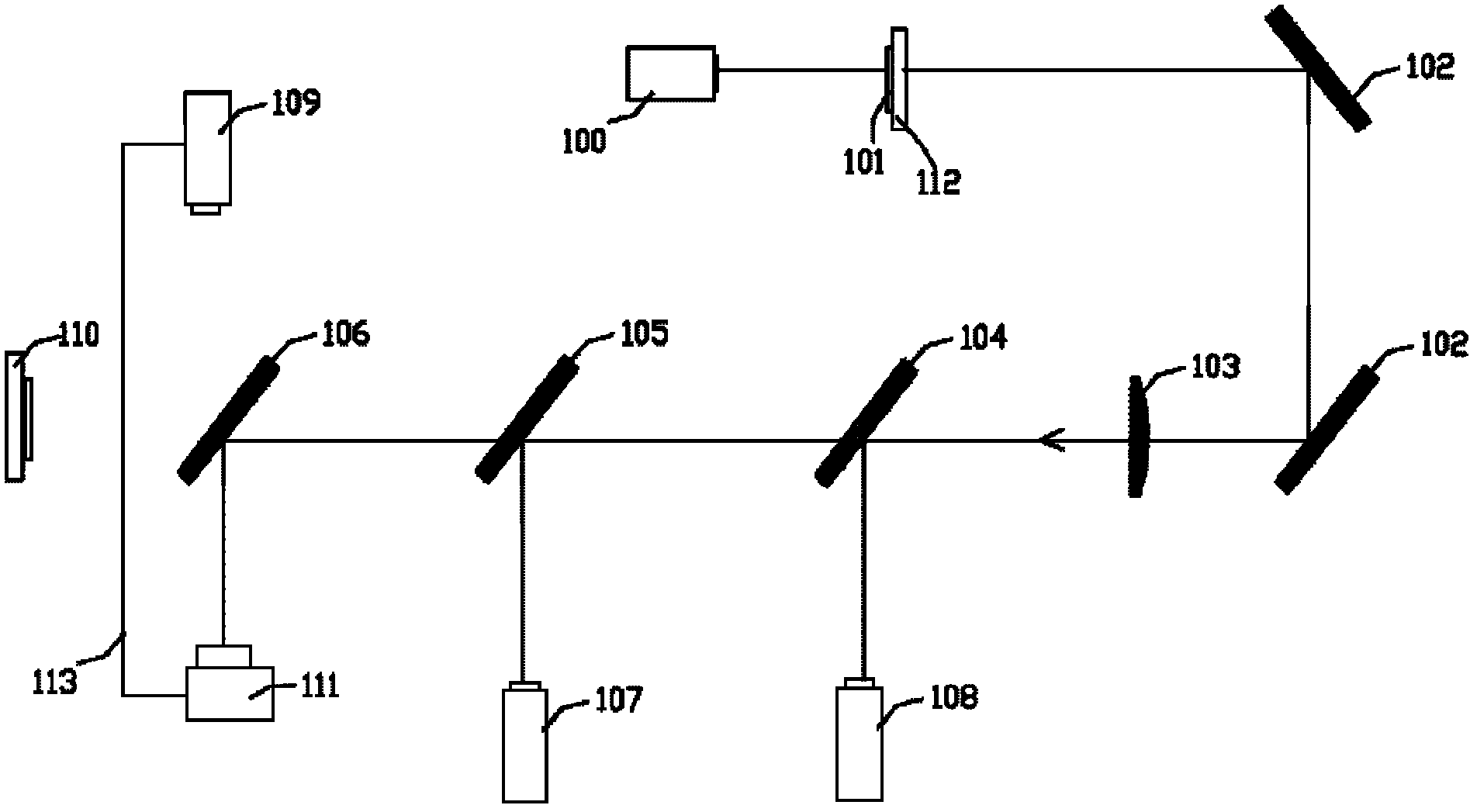

[0019] The present invention relates to a test system for the damage threshold of optical thin films, which includes a pulsed laser 100, an attenuation plate 101, a total reflection lens group 102, a converging lens 103, a window mirror 104, a beam splitter mirror 105, a total Mirror 106, an energy meter 107, a first image acquisition device 108, a second image acquisition device 109, a photoelectric probe 110, an oscilloscope (not shown), a data processing device (not shown), a carrier Object stage 111 and a rotating stage 112. The pulsed laser 100, the attenuation sheet 101, the total reflection lens group 102, the converging lens 103, the window mirror 104, the beam splitter 105 and the total reflection mirror 106 are sequentially arranged along the optical path . The energy meter 107, the first image acquisition device 108, the second image acquisition device 109, and the oscilloscope are all connected to the data processing device.

[0020] The pulsed laser 100 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com