System for measuring mass of heavy object lifted by motor by utilizing motor output power and method thereof

A technology for outputting power and heavy objects, applied in weighing, instruments, etc., can solve the problems of large sensor magnification, grid voltage disturbance, and inability to guarantee measurement accuracy, and achieve the effect of objective measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

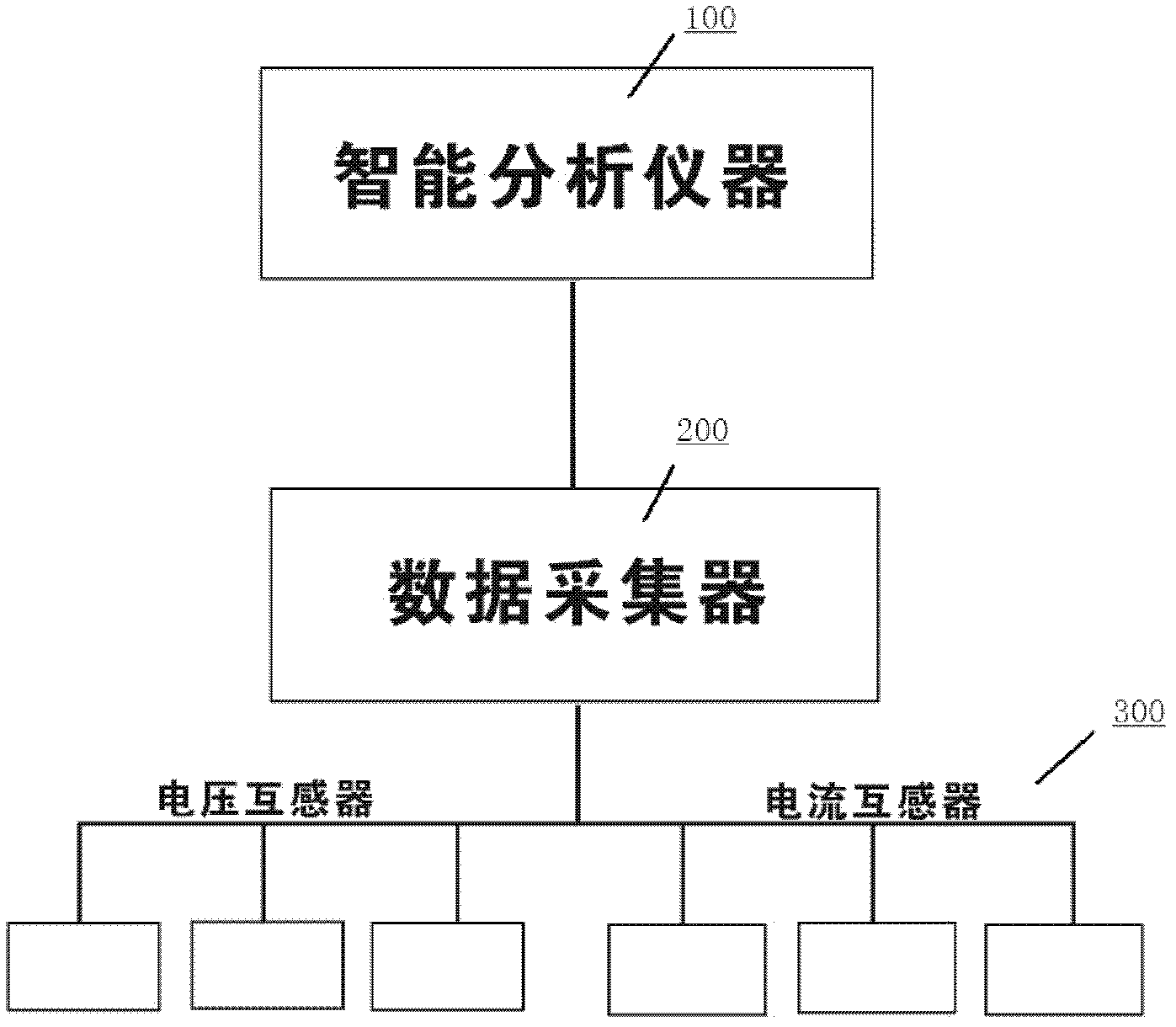

[0021] Various specific embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that this description is illustrative and not restrictive.

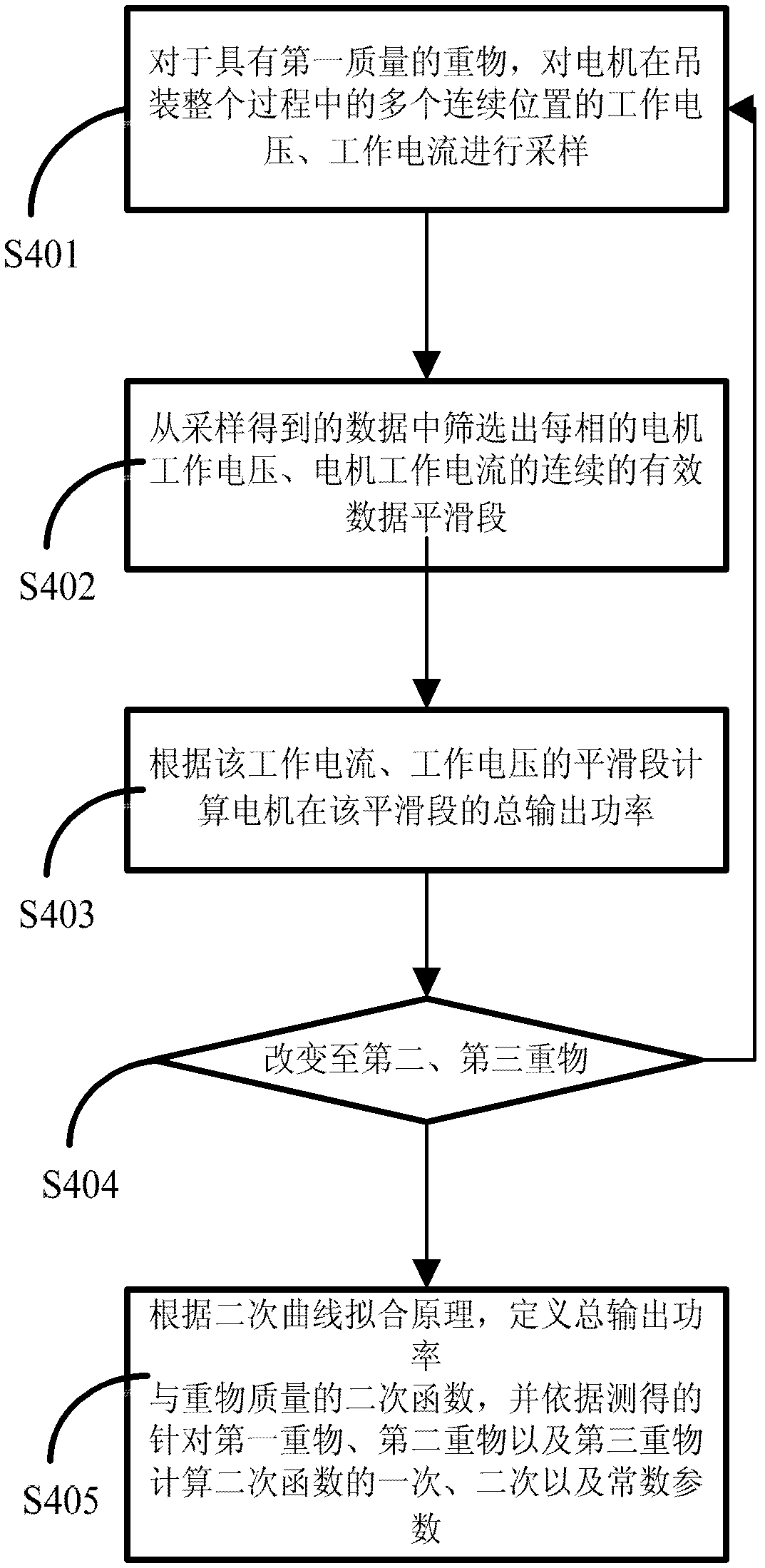

[0022] According to energy conservation, the power output provided by the motor is equal to the sum of work done by lifting heavy objects and other energy losses. According to the data analysis collected by the applicant in the field experiment, when the hoisting motor works stably near the rated speed, the output power provided by the motor has a certain function relationship f(x) with the weight of the heavy object.

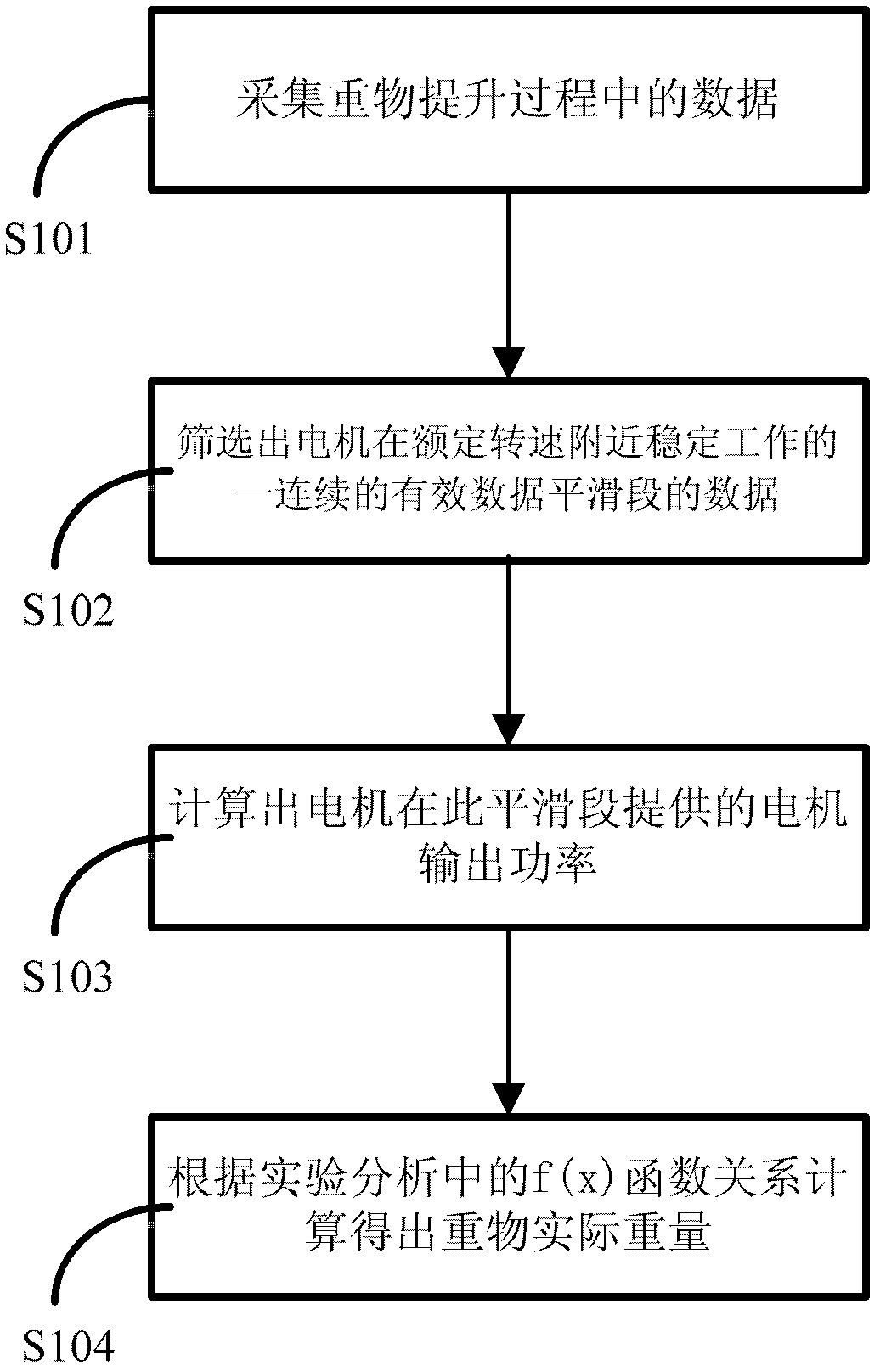

[0023] Therefore, the whole process of calculating the weight of the present invention is as follows figure 1 As shown, the data S101 in the process of lifting heavy objects is first collected, and the continuous data S102 of the motor working stably near the rated speed is screened out, and the output power S103 provided by the motor in this contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com