Composite sealing device for centrifugal machine bearing

A technology for sealing devices and centrifuges, which is applied in the direction of centrifuges, engine seals, mechanical equipment, etc. It can solve the problems of not meeting industrial requirements and affecting the service life of rotating parts such as spindles and bearings, so as to improve service life and reduce bearings. temperature, the effect of improving the usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following are preferred embodiments of the present invention, but they do not limit the protection scope of the present invention.

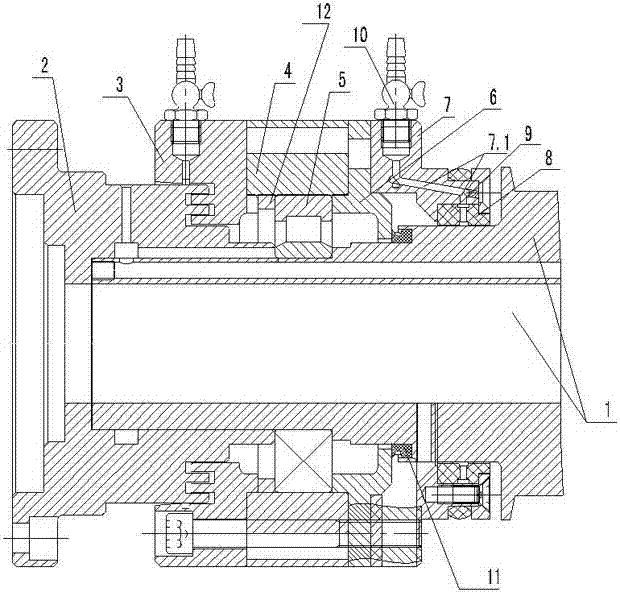

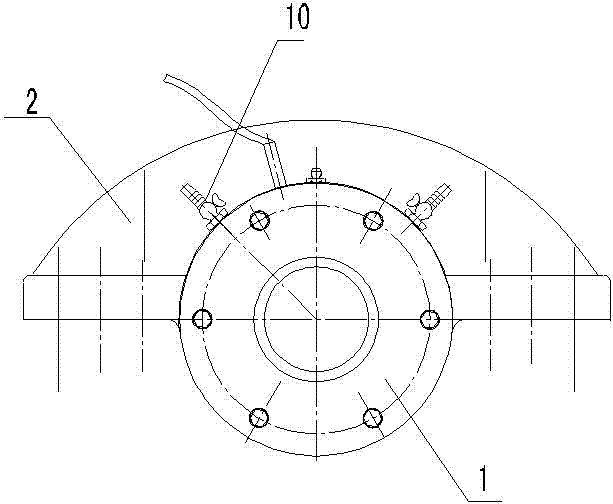

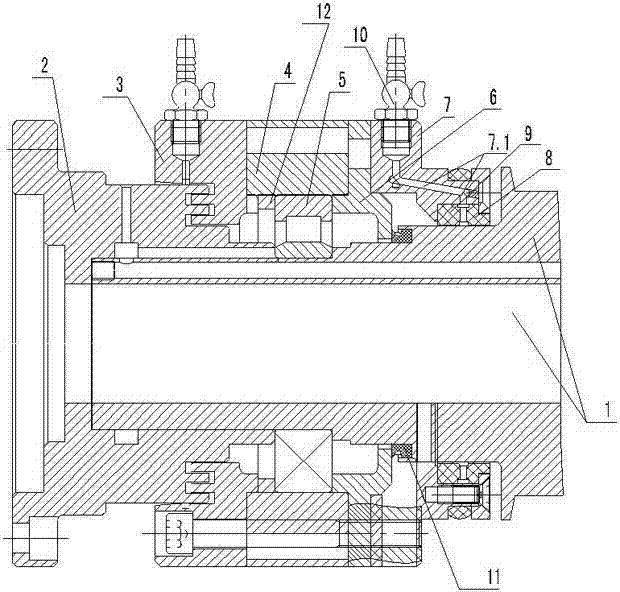

[0013] refer to figure 1 with figure 2 As shown, a centrifuge bearing composite sealing device of the present invention includes a transmission cover 2, a bearing outer cover 3, a bearing seat 4, a bearing 5, a bearing inner cover 6, The sealing bracket 7 and the sealing gland 8 are provided with a sealing element 9 between the sealing bracket 7 and the drum main shaft 1. The sealing bracket 7 is provided with an air-tight channel 7.1, and the inner end of the air-tight channel 7.1 is close to the drum main shaft 1 The outer surface is located between the sealing element 9 and the sealing gland 8, and the outer end of the air-tight channel 7.1 is connected with a high-pressure gas source 10.

[0014] Said sealing element 9 is screwed onto the drum spindle 1 .

[0015] An oil seal 11 is provided between the bearing inner cover 6 nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com