Dual-channel hydraulic suspension of engine

A hydraulic mount, dual-channel technology, used in power plants, mechanical equipment, jet propulsion devices, etc., can solve the problems of inability to achieve isolation, vibration reduction and sound insulation, reduce resonance generation, improve vibration absorption capacity, and reduce vibration frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

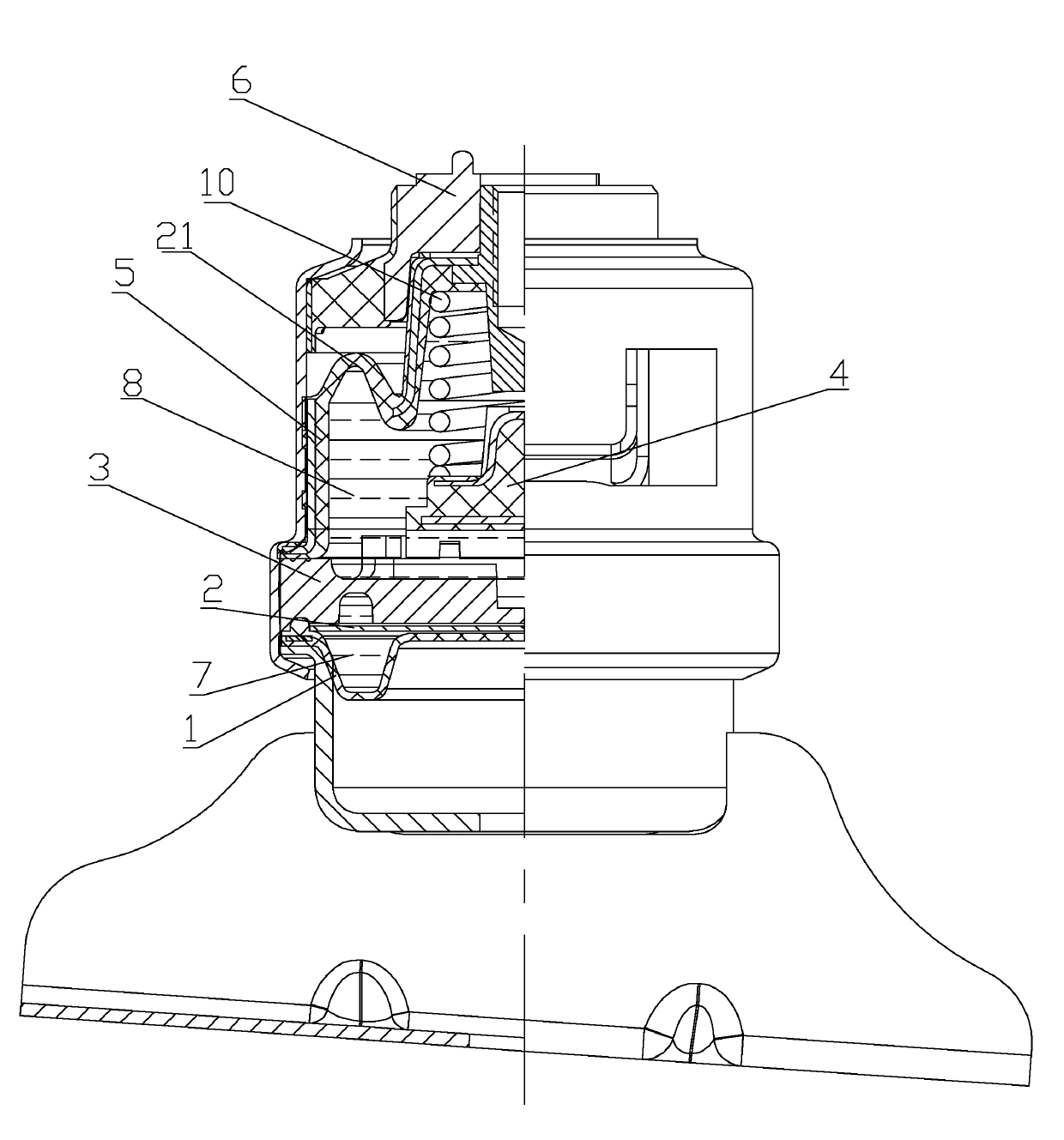

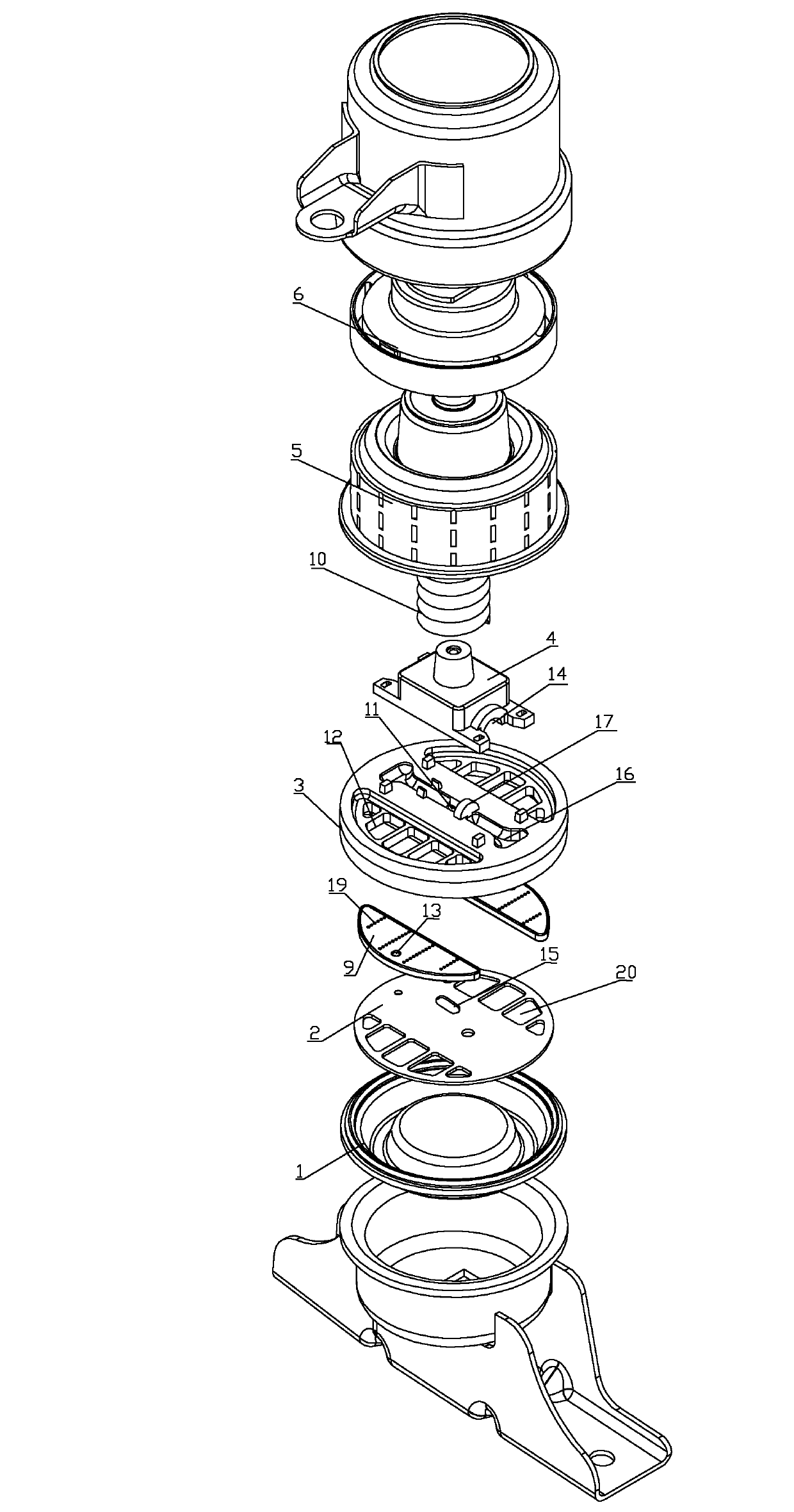

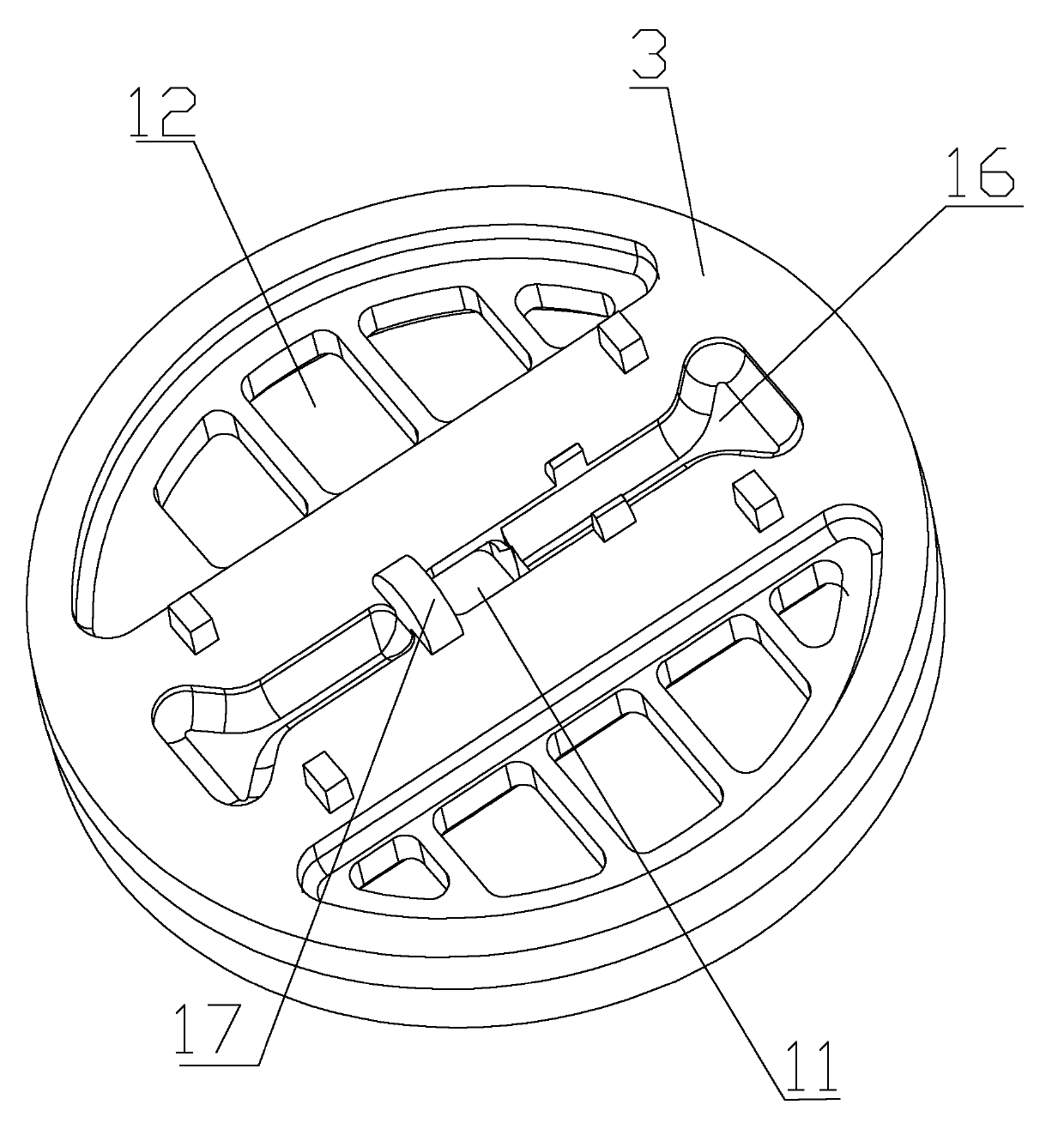

[0032] exist figure 1 In the shown embodiment, a dual-channel hydraulic mount for an engine is provided. A main liquid chamber and a slave liquid chamber are arranged inside the hydraulic mount, and a top block is arranged between the main liquid chamber and the slave liquid chamber. Flow channel plate, decoupling sheet, iron partition, the main liquid chamber and the secondary liquid chamber are filled with liquid, and a low-frequency vibration-damping fluid channel and a high-frequency High-frequency damping fluid channel, the low-frequency damping fluid channel is arranged along the top block 4, the runner plate 3 and the iron separator 2, and the high-frequency damping fluid channel is arranged along the runner plate 3, the decoupling plate 9 and the Iron clapboard 2 set. The hydraulic suspension is also provided with an inner core 5, the inner core 5 is buckled on the runner plate 3 in a bell-shaped structure, and the outer shell of the inner core 5 is provided with an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com