Rim bolt

A technology of rim bolts and bolts, which is applied in the field of devices for fastening or fixing components or mechanical parts, can solve problems such as uneven force, poor loosening performance, loose rim bolts, etc., to eliminate processing or assembly errors, improve The effect of using performance and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

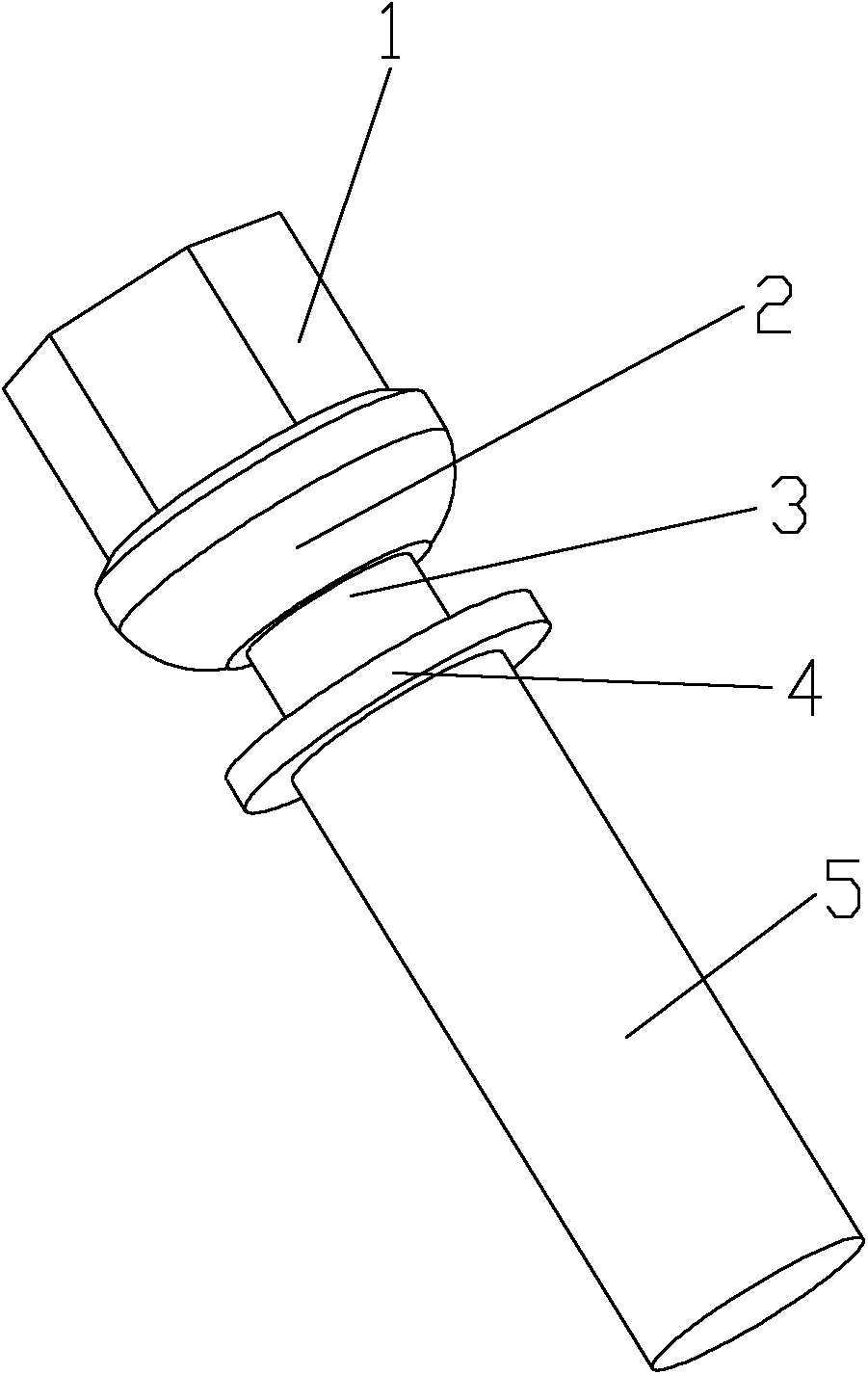

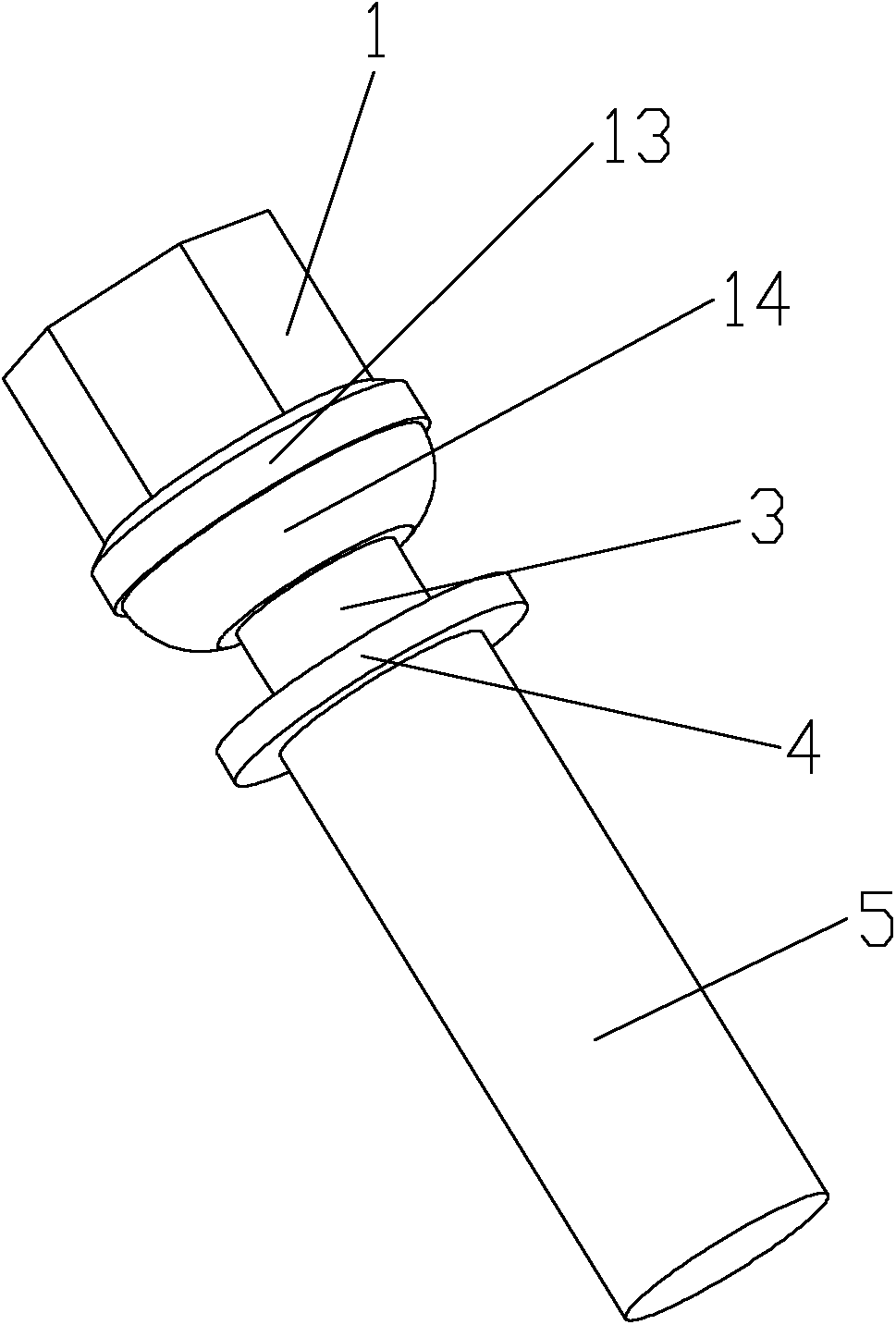

[0015] as attached image 3 The shown rim bolt of the present invention includes a bolt body, and the bolt body is formed by sequentially connecting a bolt head 1, a first step 13, a first screw rod 3, a second step 4 and a second screw rod 5; The first screw 3 is provided with a spherical elastic washer 14 ; the spherical elastic washer 14 is a spherical rubber washer and is located below the first step 13 .

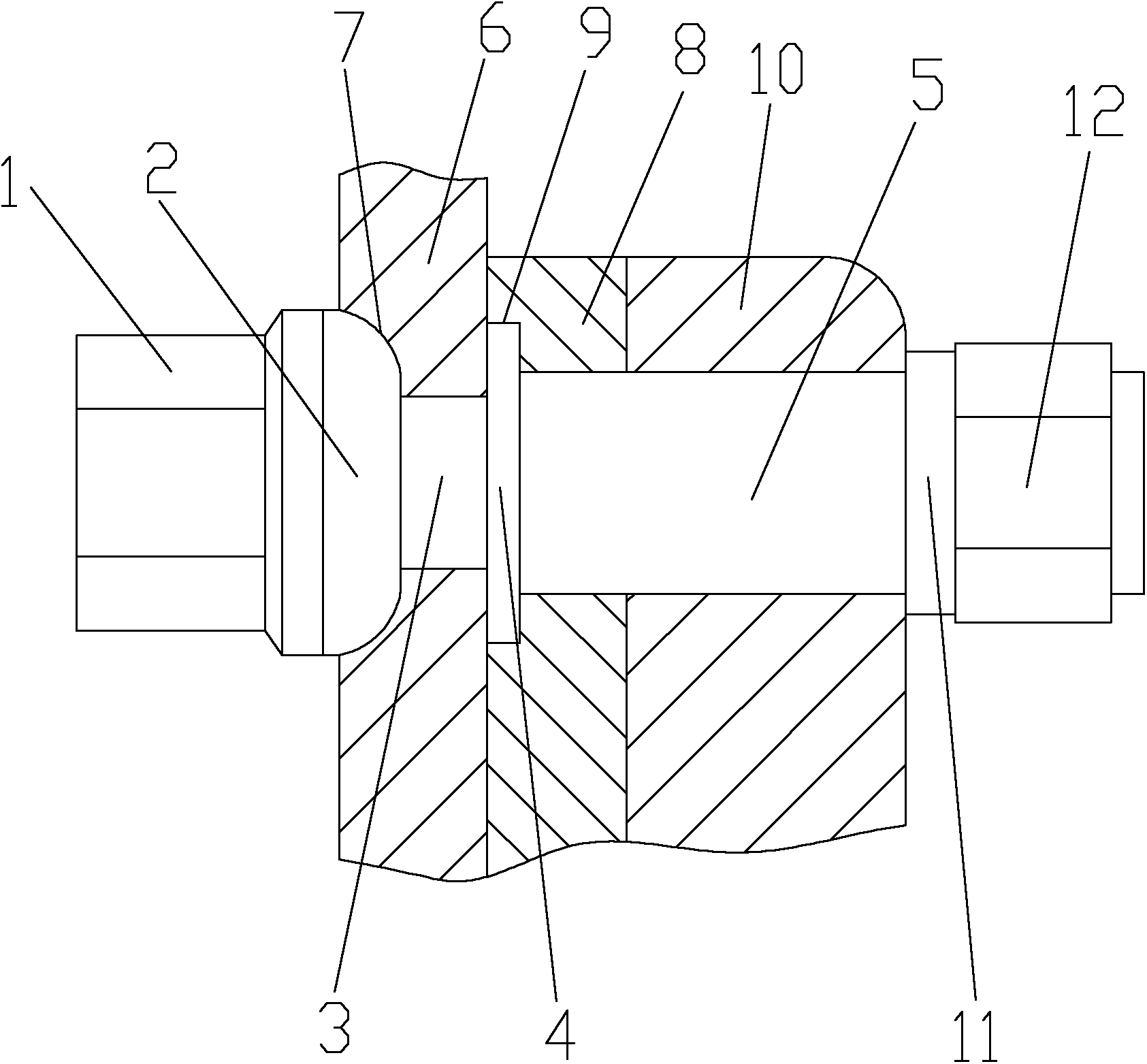

[0016] as attached Figure 4 A rim bolt according to the present invention is shown, the spherical rubber washer of the rim bolt is in contact with the spherical concave surface 7 of the rim 6, the first screw rod 3 passes through the rim 6, and the second step 4 of the rim bolt is stuck on the planetary wheel carrier 8 In the annular groove 9 of the end face, the second screw rod 5 passes through the planetary wheel carrier 8 and the hub 10, and finally the washer 11 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com