Drop hammer type pile sinking device and pile sinking method thereof

A technology for driving piles and hanging hammers, applied in the field of port engineering, can solve the problems such as the inability to meet the water depth of the piling ship, the high construction cost, and the inability to carry out the construction of the piling ship, so as to improve the construction quality and construction efficiency, the convenience of manufacture and construction, and the structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

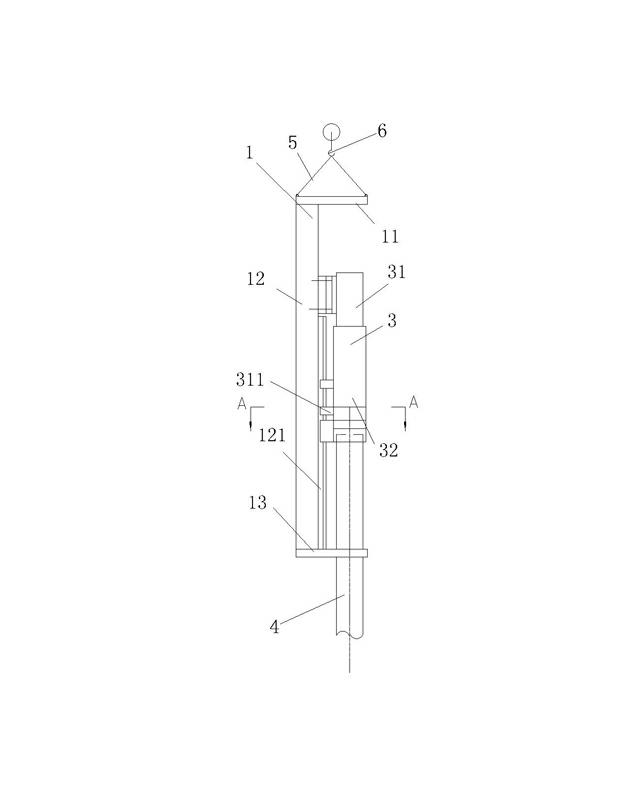

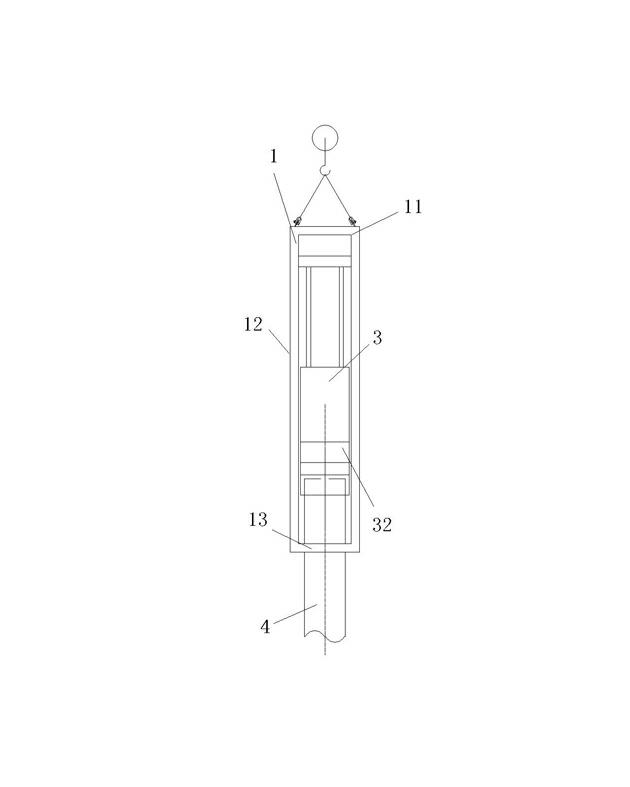

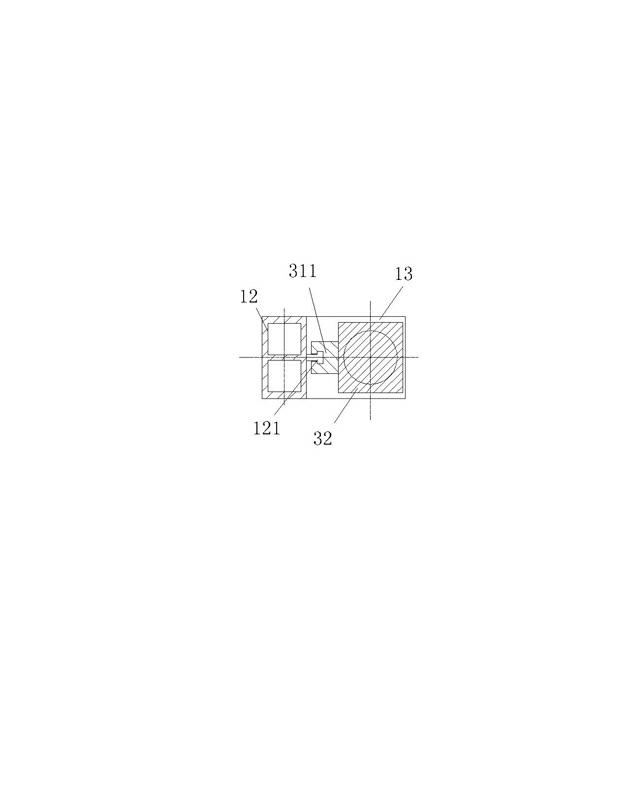

[0029] Such as Figure 1 ~ Figure 3 As shown, the pendant hammer pile sinking device of this embodiment includes a pendant hammer guide frame 1 and a pile sinking support frame 2. The pendant hammer guide frame 1 includes an upper suspension frame 11, an upright guide seat 12 and a lower engineering pile support that are connected as one. Seat 13, the upright guide seat 12 is provided with vertical guide rail 121, and the hammer body 31 of power hammer 3 is fixed on the upright guide seat 12 upper end, and the tup 32 of power hammer 3 is supported on the vertical guide rail 121, and the lower engineering pile support seat Have the circular hole that can accommodate engineering pile 4 tops in 13, engineering pile 4 tops are supported in the lower engineering pile support seat 13, and the hammer guide frame 1 top is suspended on the hook 6 of crane by sling 5. figure 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com