Simply supported-continuous construction method for bridge superstructure

A simple-support variable-continuous construction method technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large environmental impact, long construction period, and easy damage to bridge decks with cracks in inclined sections, and achieves low cost and overall Good performance and the effect of overcoming cracks in oblique sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

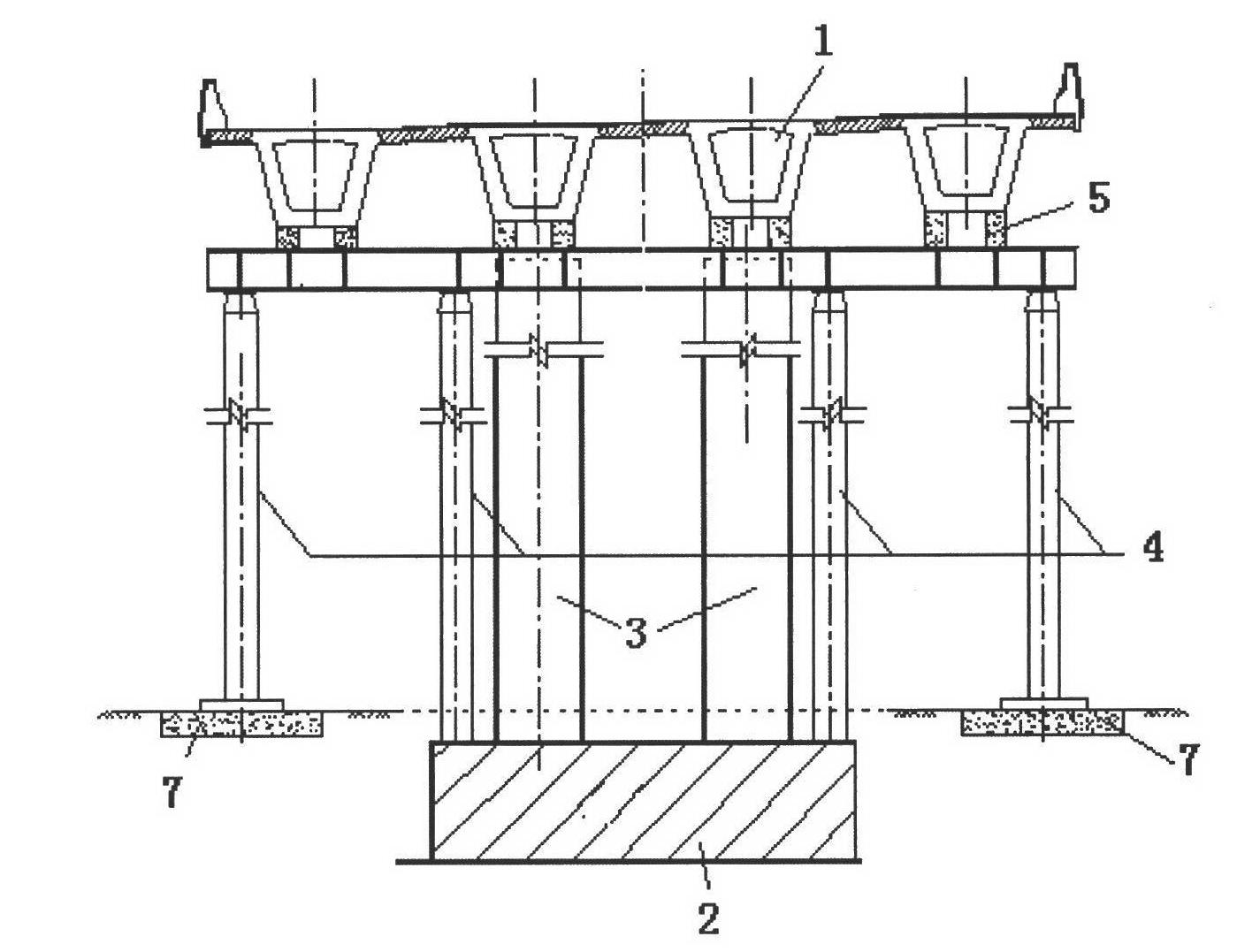

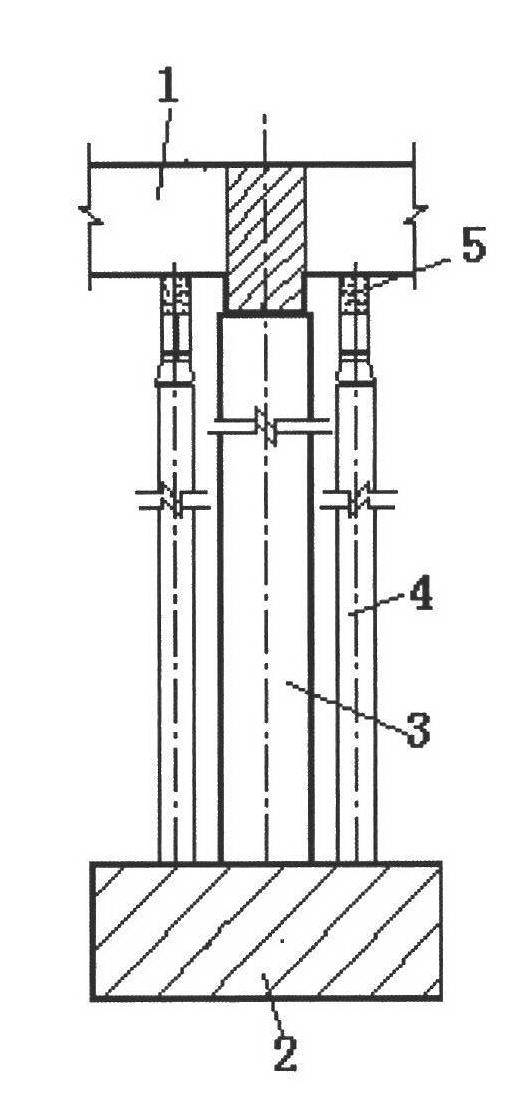

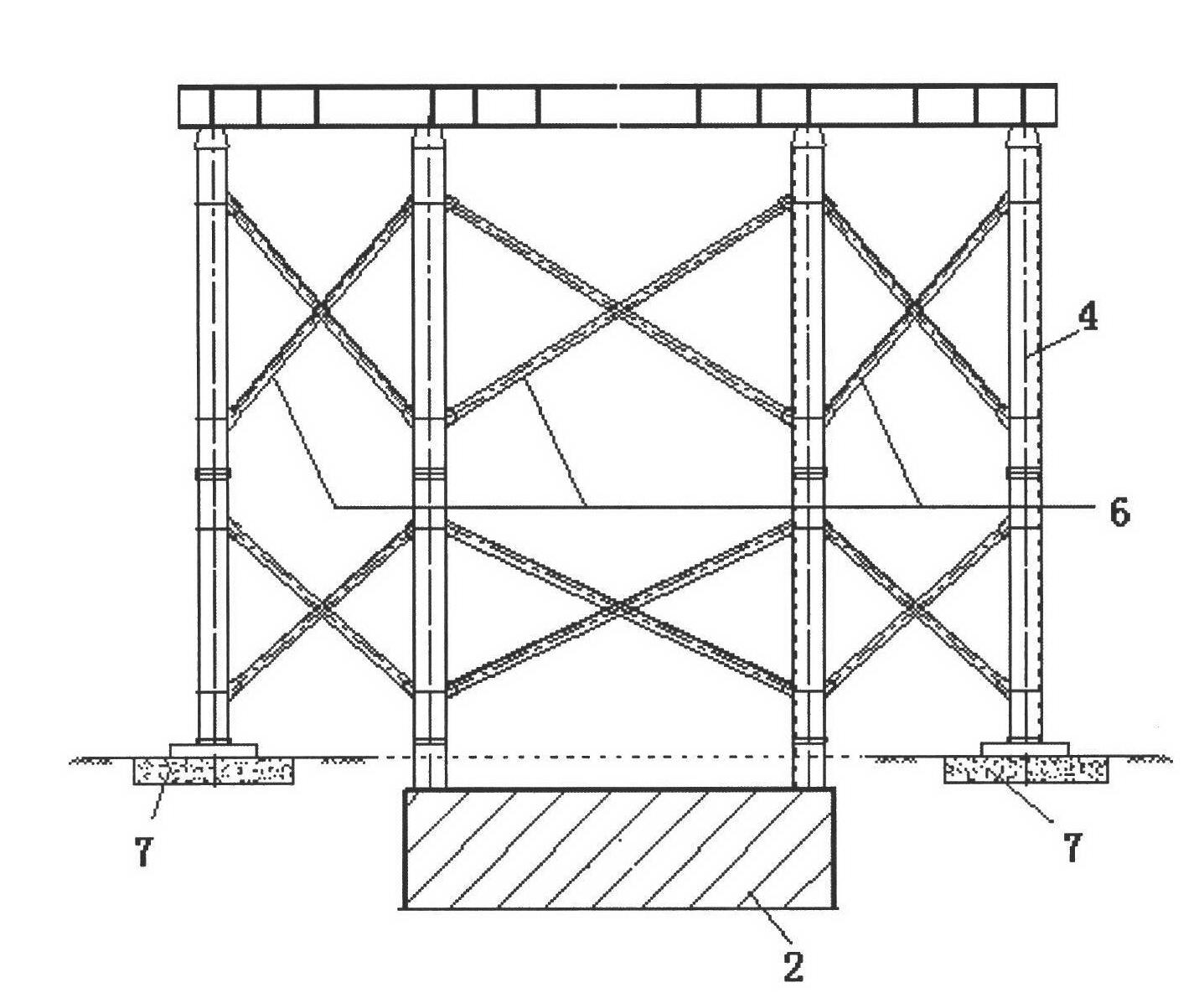

[0023] Such as Figure 1 to Figure 10 As shown, a simple-supported variable continuous construction method for the bridge superstructure, first prefabricated small simply-supported box girders 1 in batches, and then installed temporary steel brackets 4 on both sides of bracket steel pipe columns 3 standing on the cap 2, temporarily A temporary support 5 with adjustable elevation is installed on the top of the steel bracket 4, and the prefabricated simply supported small box girder 1 is hoisted to the temporary support 5 on the temporary steel bracket 4, and then the beam between the simply supported small box girders 1 The transverse prestressed tendons 8 are arranged at the position, and the longitudinal negative moment beams are arranged through the holes reserved on the top surface of the simply supported small box girder 1, and the beam concrete 8 is poured. Prestressed continuous beam system.

[0024] The main construction steps of the bridge superstructure using the sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com