Manufacturing process for cement-base plastic track coiled material

A technology of plastic track and roll material, which is applied to roads, roads, rubber layered products, etc. It can solve problems such as delamination, inconvenient transportation and installation, and foaming of runway rubber rolls, and achieves the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Concrete manufacturing process of the present invention is as follows;

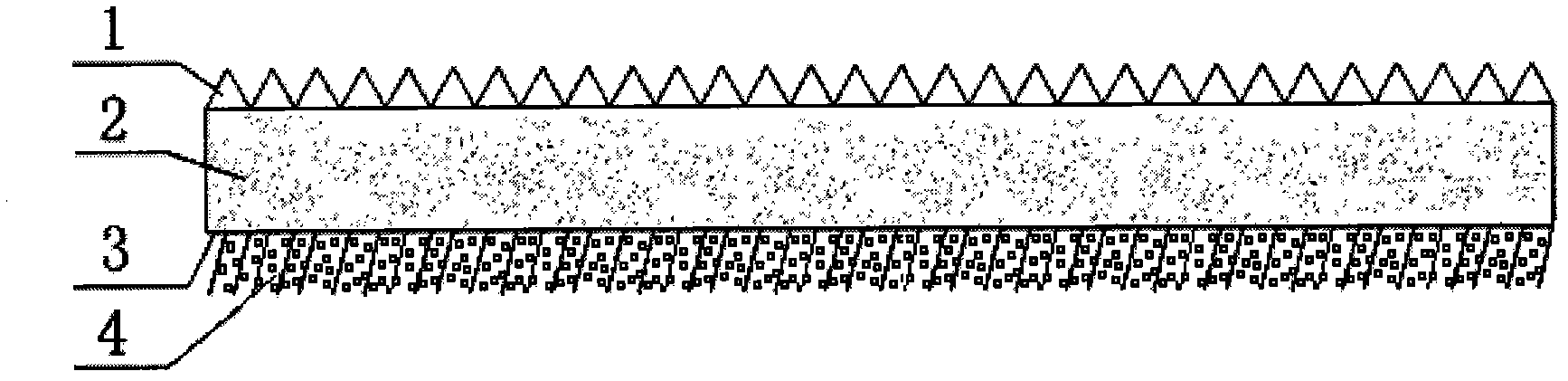

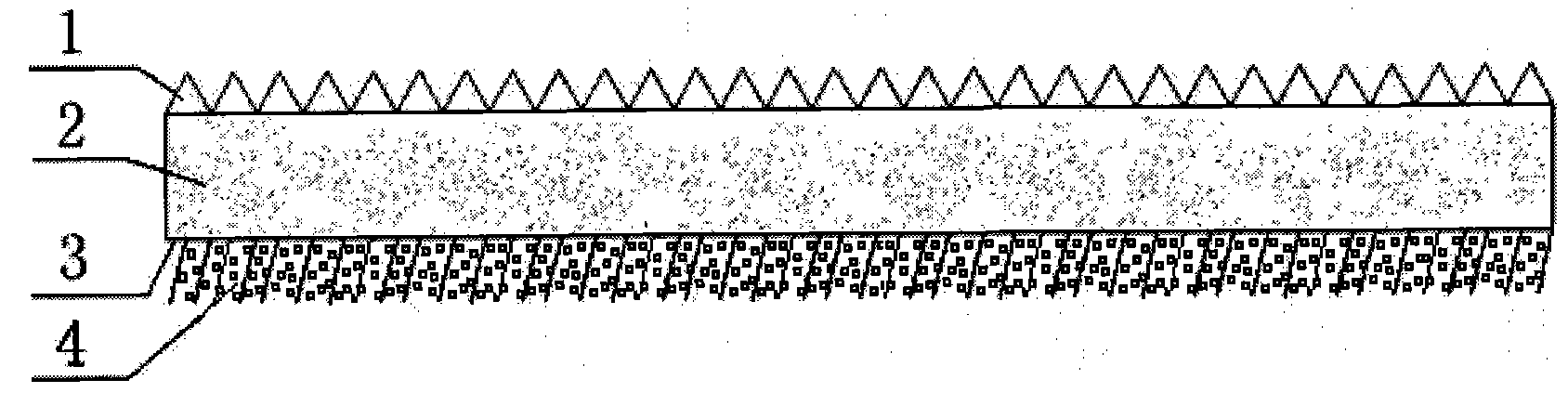

[0011] Step 1: Continuously pour colored polyurethane elastomer liquid on the silicone base belt with evenly arranged concave-convex patterns on the circular running surface, fix the straight silicone scraper above the silicone base belt and cling to the running silicone base belt, and pour the colored polyurethane elastomer The liquid is scraped and filled into the concave holes on the surface of the silicone base belt, and filled up to the convex surface; thin colored polyurethane elastomer liquid remains on the convex surface of the silicone base belt.

[0012] Step 2: Place the rubber particle coil on the top of the silicone base belt and stick it close. The thin colored polyurethane elastomer liquid remaining on the convex surface of the silicone base belt is attached to the rubber particle coil, and the colored polyurethane elastomer liquid part enters the rubber particle groove.

[0013] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com