Carbon fiber cloth loom

A cloth loom and carbon fiber technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems that scissors cannot meet the cutting requirements of weft yarn pieces, carbon fiber materials have poor wear resistance, and weft insertion reliability is low, so as to improve the use of The effect of simplifying the service life and weaving requirements and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

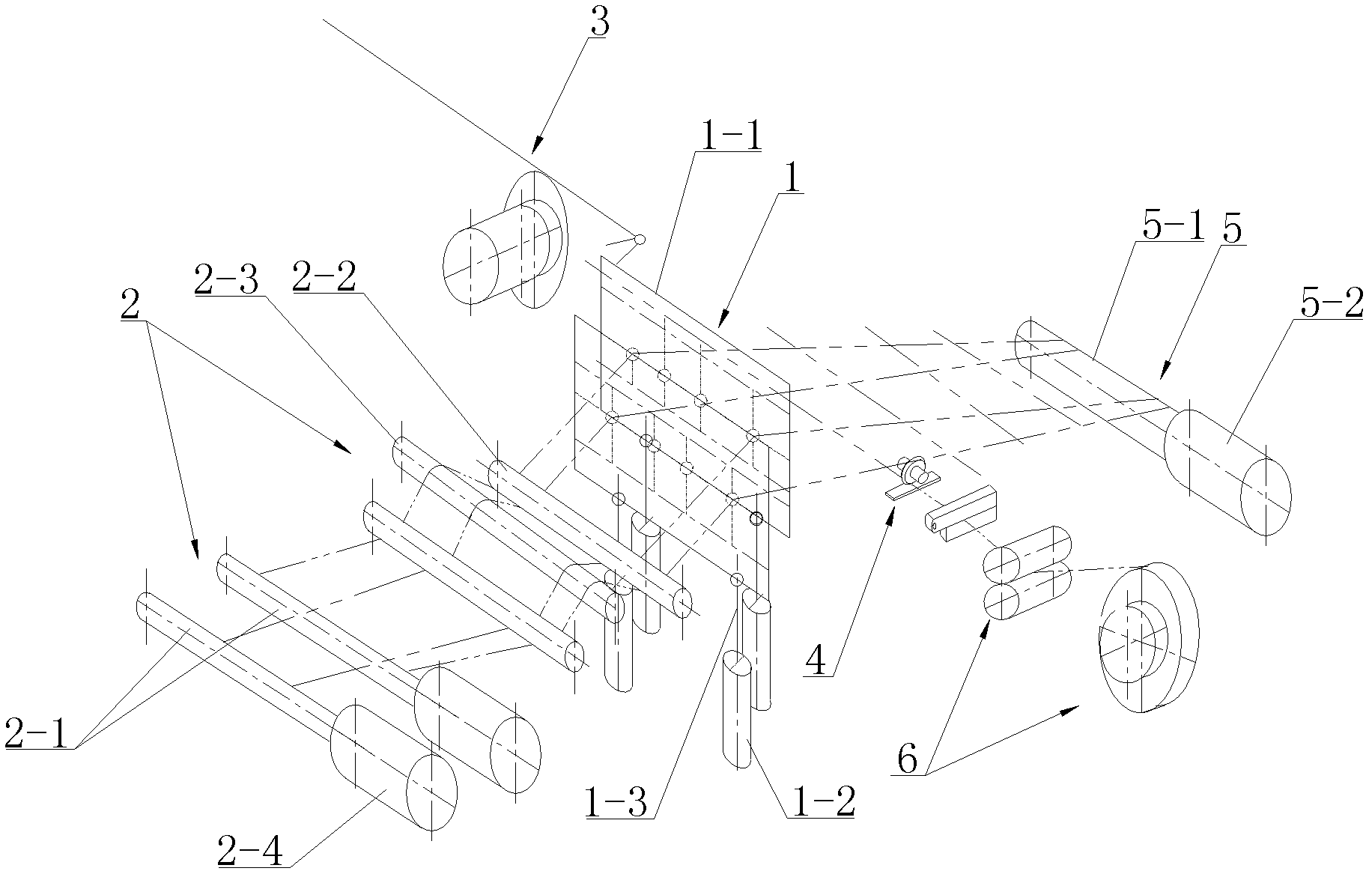

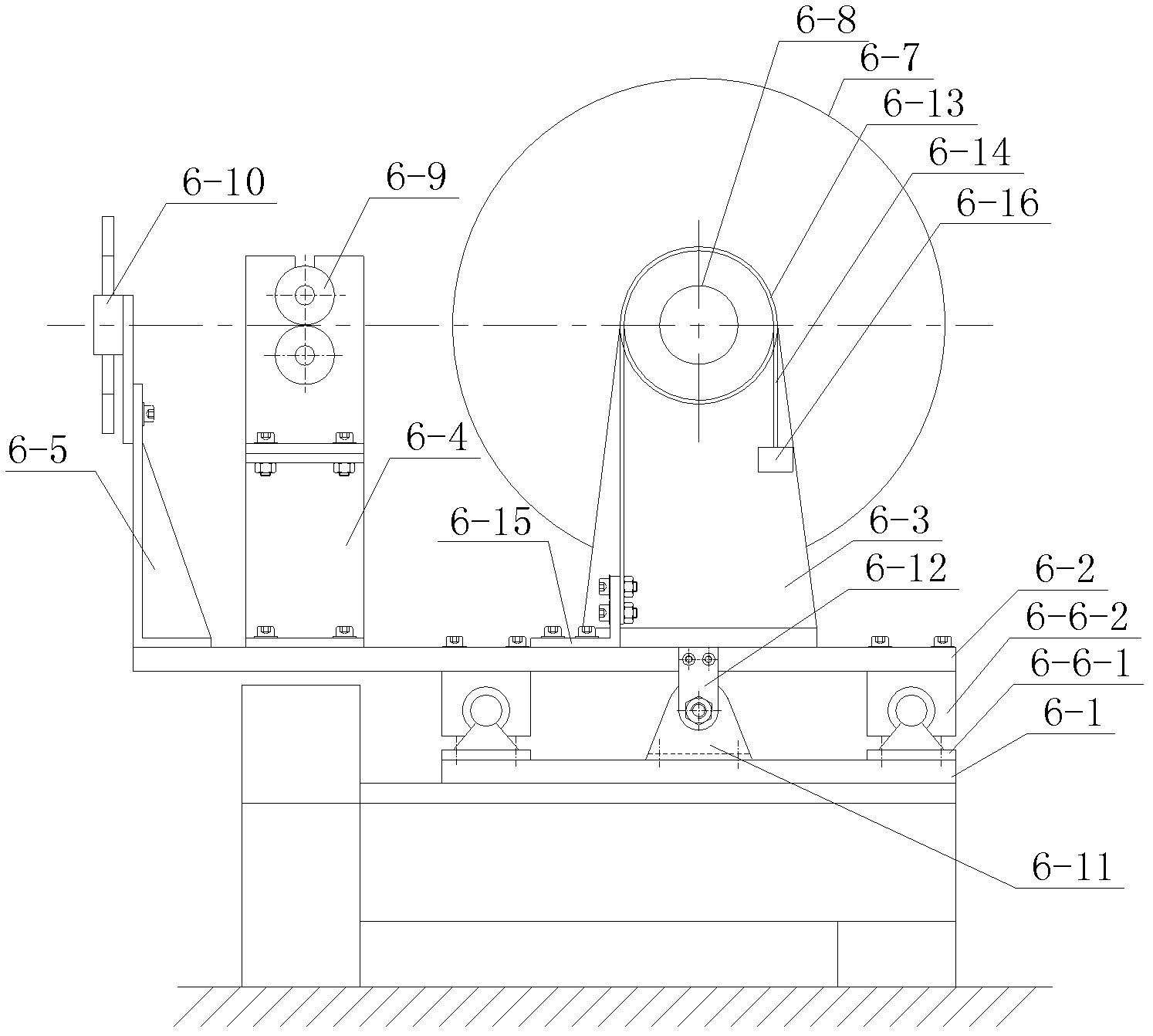

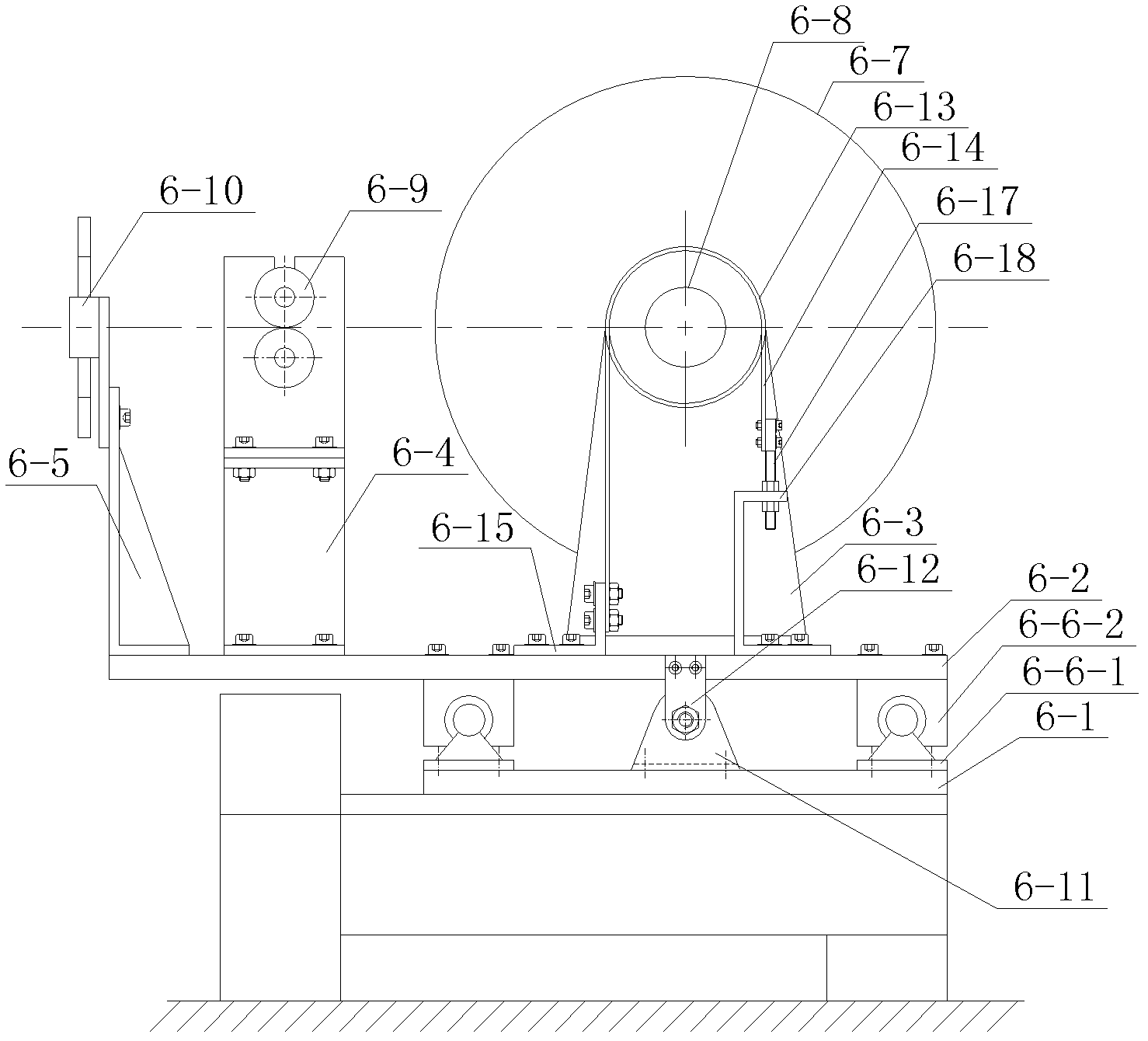

[0038] see Figure 1-9 , a carbon fiber cloth loom, including a frame, a shedding mechanism 1, a let-off mechanism 2, a weft insertion mechanism 3, a weft yarn cutting mechanism 4, and a take-up mechanism 5, and also includes an automatic weft-laying and weft-feeding mechanism 6. The weft insertion mechanism and the automatic weft putting and weft feeding mechanism are respectively located on both sides of the frame. Specifically, the frame is used to support the let-off mechanism, the shedding mechanism and the take-up mechanism; the let-off mechanism supplies warp yarns according to the needs of interweaving, and makes the warp yarns have a certain tension; the shedding mechanism separates the warp yarns up and down according to the fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com